- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

800-2000 bags/h

-

Weight (KG):

-

1000

-

Voltage:

-

220V/380V/50/60Hz

-

Place of Origin:

-

China

-

Speed:

-

800-2000bags/h(adjustable)

-

After Warranty Service:

-

Video technical support

-

Main Function:

-

Bag Palletizing

Quick Details

-

Function:

-

Wrapping, Laminating

-

Packaging Type:

-

Cartons, Bags, case

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

800-2000 bags/h

-

Weight (KG):

-

1000

-

Voltage:

-

220V/380V/50/60Hz

-

Place of Origin:

-

China

-

Speed:

-

800-2000bags/h(adjustable)

-

After Warranty Service:

-

Video technical support

-

Main Function:

-

Bag Palletizing

|

Pallet height

|

≤2400mm(with pallet)

|

|

Bags per layer

|

3~8(depending on bag size)

|

|

Palletizing form

|

2+3/3+2,3+3,2+4/4+2,2+2+3/3+2+2, 3+3+2/2+3+3(depending on bag size)

|

|

Bag weight

|

10~50 kg/bag

|

|

Pallet material

|

Wooden pallet, engineering plastic pallet, iron pallet, corrugated paper pallet

|

|

Fork form

|

Two-sided or four-sided fork

|

|

Pallet size

|

Length 800~1400mm, width 800~1200mm, height 80mm~200mm

|

|

HP-1200

|

800 ~ 1200 bags / hour (all kinds of pockets and palletizing form)

|

|

HP-1600

|

1200~1600 bags / hour (no less than 5 bags per layer for all kinds of pockets)

|

|

HP-2000

|

1800~2000 bags / hour (not less than 5 bags per layer of conventional valve pocket and building material valve pocket)

|

High Level Palletizer:

* High speed: the desired speed can reach 1200-1600bags per hour, it is the quickest way to palletizer;

* The best palletized result, the finished pallet is good pattern, the bags are not easy to slide off;

* Keep the bags safe at the most, it is not easy to damage bags;

* Can be used in high altitude area;

* Long lifetime: min. 15 years;

* Cost effective.

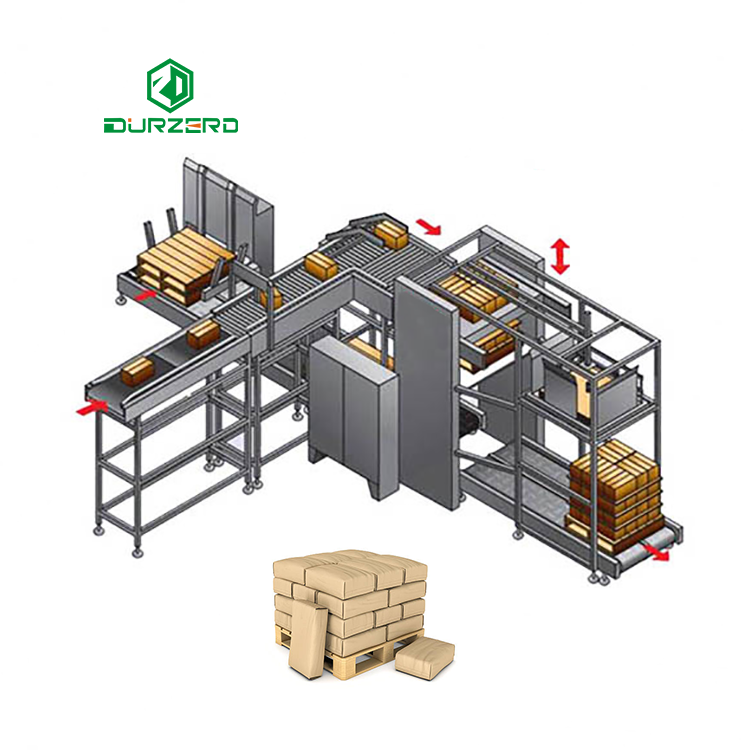

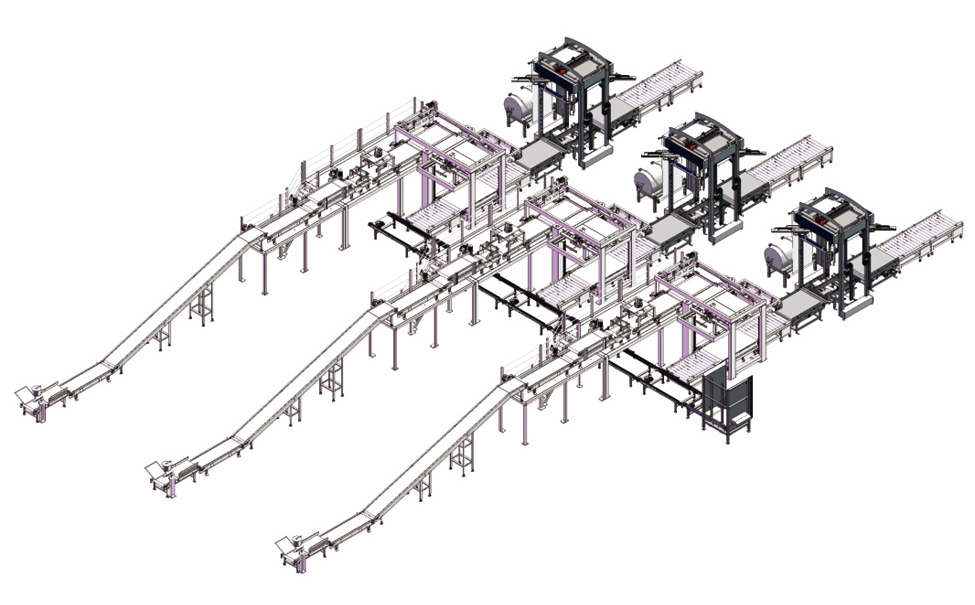

1. The High-level Palletizer Production Line adopts the modular design, modular setup can be different according to the different requirements of customers.

2. Full-automatic Packaging Machine is equipped in the packaging part.

The production line includes High-speed Sewing System, Pushing and Convey Mechanism, Double-level Flatting and Convey Mechanism, Transposition Marshalling Mechanism, High Level Palletizer, Automatic Film Packaging Machine,

3. Automatic Pallet Storehouse, and Pallet Convey System. The actual output of production line can be up to 1200 bags/h.

4. The Metal Detection System and the Weight Detection System can be equipped per customers’ requirements to get rid of unqualified products to ensure product quality.There is Automatic Industrial Inkjet Printer to help customers recognize and retrospect products, this enhance the control and management of products.

5. Film Packaging Machine replaces Online Winding Machine, which makes the pallets steadier in order. Film Packaging Machine can film 60 stacks/h, it increases the output of production line. And using stretched film instead of wrapping film reduces production costs.

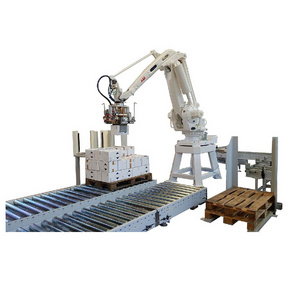

1. Flatten Bag

Use a conveyor with double belt to flatten the bags that enter the High-level Palletizer.

2. Rotate Bag

The clamping and rotating mechanism selectively rotates the material bag 90 or 180 degree angle according to the established procedure to achieve the direction required for the material bag grouping.

3. Cache Bag

Ensure that the distance between the bag and the bag is in a stable state, and avoid the collision of the two bags and affect the stacking effect.

4. Grouping Bag

It consists of a belt conveyor and a stainless steel buffer plate. On the belt conveyor, the bags are grouped in a 3+2 or 2+3 type.

5. Push and Press Bag

Push the grouping bag onto the layered door, and open the layered door to drop the bags onto the pallet. After the layered door is closed, the bag pressing device and the surrounding shaping mechanism are used for all-round compaction and shaping.

6. Empty Pallet Input

The empty pallets from the pallet library are transported to the lifting roller conveyor, which is lifted up by the lifting mechanism to place the material bags coming down from the layered door.

7. Full Pallet Output

Repeat steps 1-6 to stack the material bags on the pallet layer by layer. After reaching the set number of layers, the full pallet will be lowered to the bottom by the lifting mechanism and output to the next station.

Q1: Are you a factory or a trading company?

A1:We are the factory with manufacturing and self-supporting import and export rights for more than 25 years.

Q2: How to choose suitable packaging machine?

A2:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How about the payment way?

A3:Payment can be T/T, L/C etc. we can provide FOB, CNF, CIF term by sea.

Q4: How to ensure the quality of the machine?

A4:We usually delivery the machine after successful inspection in our factory. We have our own quality control department,before the delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q5: How to install the equipment?

A5:We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Hot Searches