- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

Lantai

-

Voltage:

-

Depends on customer

-

Dimension(L*W*H):

-

Depends on design

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Free spare parts

-

Name:

-

Extrusion Machine

-

Usage:

-

Wide Usage

-

Processing Type:

-

Exturding Machine

-

Color:

-

Require

-

Automatic Grade:

-

Auto

-

Power(W):

-

200/75 kW

-

Output (kg/h):

-

220 - 600 kg/h

-

Certification:

-

CE

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

55:1

-

Screw diameter (mm):

-

72.3 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

Lantai

-

Voltage:

-

Depends on customer

-

Dimension(L*W*H):

-

Depends on design

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Free spare parts

-

Name:

-

Extrusion Machine

-

Usage:

-

Wide Usage

-

Processing Type:

-

Exturding Machine

-

Color:

-

Require

-

Automatic Grade:

-

Auto

-

Power(W):

-

200/75 kW

-

Output (kg/h):

-

220 - 600 kg/h

-

Certification:

-

CE

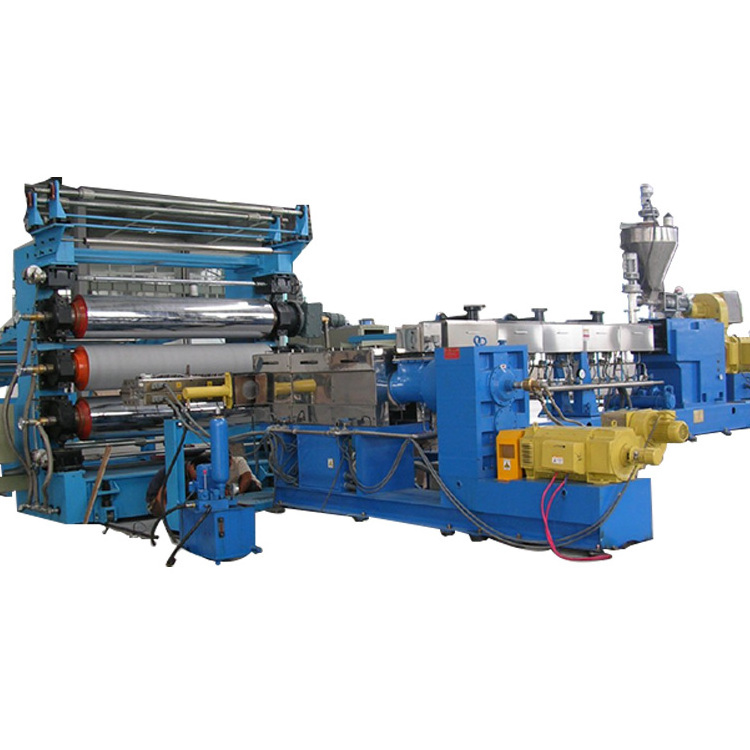

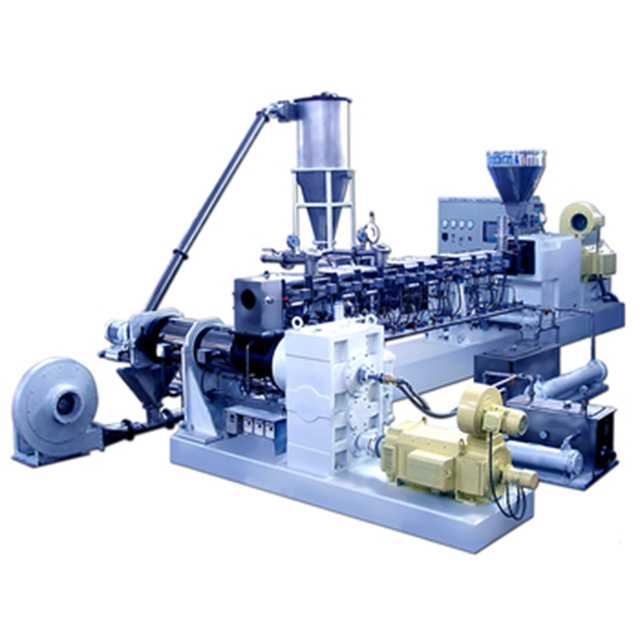

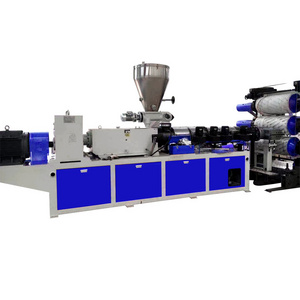

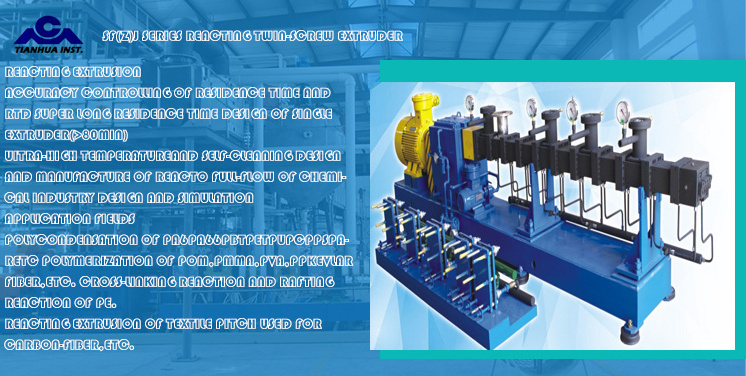

The STJ series twin-screw extruders hasve screw threads made of high grade steel with a five-axis machining tool to reduce clearance and wear.

This twin screw extruder is equipped with PLC controllers and high-level touch screen panels for manual or automatic operations. The extruder’s operating parameters are input and displayed on the touch panel. Designed by CAD, the closely intermeshed screw elements have excellent self-wiping characteristics, and can be interchanged with each other easily. Besides, twin-screw compounding extruder is installed with the newly designed torque distribution system, high-precision grinding of hardened gear teeth, and imported high-quality key bearings.

Furthermore, the system is capable of remote control. This twin screw extruder can be extensively used in many fields, such as polymer blending, homogeneity, plasticization, filling modification and granulation, engineering polymer and glass fiber reinforcement, master batch, functional parent granule, special material, power coating material and cable material reactive extrusion, degassing and devolatilization, etc.

All STJ series twin-screw compounding extruders meet or exceed CE and international safety standards. Tianhua can also design an entire twin screw extruder production line to meet customers’ specifications

Twin Screw Dia: 72.3mm

Power: 75-160kW

L/D: 20-48

Single Screw Dia: 150mm

Power: 45-75kW

L/D: 7-16

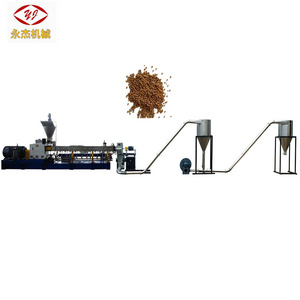

Installed loss-in-weight feeders

Air cooling die face cutter.

Conveying unit

Silo for finished products

Packing system

Can be used to produce HFFR compound, PVC, Cross-linked PE.

Also can be used to compound&extruding sheet/profile/pipe!

| Parmeters of STJ Single/Twinscrew extrudes | ||||||||||

| Type | STJ-50/100 | STJ-60/120 | STJ-75/150 | STJ-80/180 | STJ-92/120 | |||||

| double | single | double | single | double | single | double | single | double | single | |

| Screw diameter(mm) | 49.2 | 100 | 59.8 | 120 | 72.3 | 150 | 80 | 180 | 90 | 200 |

| L/D | 20-48 | 7-16 | 20-48 | 7-16 | 20-48 | 7-16 | 20-48 | 7-16 | 20-48 | 7-16 |

| Screw speed(r/min) | 300/600 | 70/90 | 300/600 | 70/90 | 300/600 | 70/90 | 300/600 | 70/90 | 300/600 | 70/90 |

| Main power(kw) | 37/55 | 18.5/22 | 45/75 | 37/45 | 75/160 | 45/75 | 160/280 | 55/90 | 220/355 | 75/110 |

| Output(kg/h) | 100-300 | 200-400 | 300-600 | 400-1000 | 700-1300 | |||||

Advantages:

1. Lantai twin-screw compounding extruders possess space saving function, elegant and compact configuration.

2. This type of twin screw extruder adopts world-class inverter and comprehensive alarm system.

3. Its reducing torque distribution system can ensure quiet running.

4. Twin-screw compounding extruder is equipped with flexible and maintenance-free air-cooling system.

5. This kind of twin screw extruder is well designed and elaborately manufactured.

Application:

1.Flame retardant and enhancement of engineering plastics

2.Blending of rubber and plastic materials

3.Automotive material

4.BOPP

5.Plastic coloring

| series | SHJ,STJ,SPJ,SSJ,SFJ,SZJ multiple co-rotating twin-screw extrusion |

| Rubber and plastic blending | Typical products: PP, PE, PS+SBS; PP, PA+EPDM; PP+NBR; EVA+silicone rubber: TPR thermoplastic elastomer, etc. |

| Plastic alloy | Typical products: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+EPDM, PP+SBS, etc. |

| Plastic coloring | Typical products: PE, PP, PS, ABS, EVA, PBT, PET, etc. + inorganic or organic pigments. |

| Fiber reinforcement | Typical products: PP, ABS, PC, AS, PBT, PET, PA6, PA66, PPS, POM, etc.+ (long fiber, short fiber, carbon fiber, metal fiber). |

| High percentage filling |

General-purpose filling: It is widely used in the filling field of inorganic fillers such as CaCO: (heavy and light), talcum powder, titanium dioxide, etc. The maximum filling rate is 93%, and good dispersibility is ensured. The volumetric gas content in the particles is within 1% or less. Typical products: PP, PE filled CaCO, inorganic flame retardant Mg(OH), open masterbatch, ferromagnetic material, AMOH), red phosphorus, SbO: filled, helium-based flame retardant filling; PP, PE+CaCO, talc Powder, titanium powder, carbon black, etc.: ABS, PC, PS, etc.+xenon alumina; PP, PA, ABS, etc.+magnetic powder, ceramic powder, iron powder: carbon black masterbatch film and color masterbatch (suitable for various films Production). |

| Special materials for automobiles |

Typical products: PP, ABSPS, PBT, PET and other reinforced flame-retardant bumpers, instrument panels, battery shells, steering wheel materials, etc.; PVC sealing strip materials. Special materials for household appliances

|

| Advantages |

1.Hydraulic and sealing technology of the openable barrel 2.Forced feeding for ultra micro-power 3.Screw combination for different type of material 4.High wear resisting technology of screw element and liner |

Application |

1.Flame retardant and enhancement of engineering plastics 2.Blending of rubber and plastic materials 3.Automotive material 4.BOPP 5.Plastic coloring |

| Thermo-setting electronic packaging material extrusion technology |

With the rapid development of electronic and information techmology, the integration level of integrated circuit improves continually. The requirement for chip manufacturing is

better.Packaging plays an increasingly important role in the chip manufacturing. So the electric packing is becoming an independent industry with rapid development and its

market demand is increasing rapidly.

The electric packaging material includes metal and non-metal. The former is used for spaceflight and navigation. The latter is also called plastic packaging which is becoming dominant because of its low cost and simple process, The epoxy resin plastic is the optimum which accounted for about 95% of the total material. As the processing base of eloctric product and integrated circuit, our country has a rapid demand for epoxy resin packaging material. According to the market demand, TIANHUA Co., Ltd.Combines 50 years of expertise of manufacturing co-rotating Twin-screw extruder and makes special equipment, like openable barrel Twin-screw extruder, table press, cold brand granulation equipment and etc. Through continuous optimization and development, we have developed series production line which reached 15-1500 kg/h. The performance of the equipment keeps up with the advanced levels of the same products abroad. Compare with the more applied double roller open mill, the openable barrel twin-screw extruder has superior compounding performance, uniform heat transfer, closed continuous production, steady quality, self-clean function and narrow resistance time distribution. It does not need clean the equipment to replace the material with different color. So this kind of extruder adapts to a variety of materials to extrude steadily and continuously. In addition, the equipment can react accompanied with polymerization and chemical combination which is beneficial to new product development. |

|

SHJ series is the extruding line used for general-purpose polymers processing, it is one of competitive products of TIANHUA. I can be used for compounding, flling, reinforcement, degradation, coloration, grafting,crosslinking etc. lt can also process retardant master batch,filled master batch,master batch, biaxially oriented film, flame retardant sheet, automobile compounding. thermo-plastic elastomer,rubber & plastics blending,etc.

TIANHUA owned thedesign technology of completely self-cleaning screw, with uniformed screw clearance and excellent mixing effects,can process all kinds of polymer. TIANHUA has been used finite element analysis method to simulate the material flow in channel during the design.This can help us to know well of the working conditions and to justify the final performance of processed materials. TIANHUA used special design flow channel of barrel,which can ensure the same deformation and pretend unusual deformation under high temperature.The multi-channel design can enhance the heat transfer capacity effectively and improve the accuracy of the temperature control. The series of SHJ(H)and SHJ(S) are high performance and super high performance extruding line with wide die, high performance transfer system and screw shafts.SHJ(H),SHJ(S) machines have higher performance with lower price. |

|