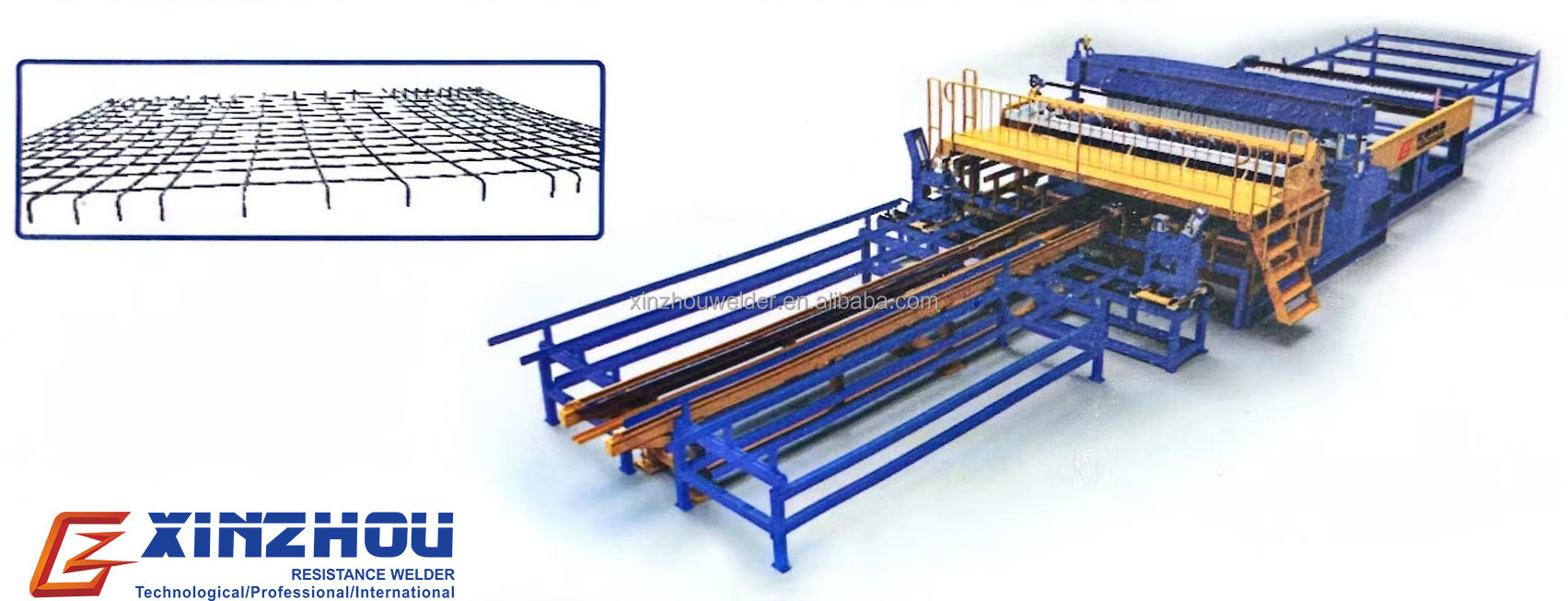

1.This series is suitable for producing the mesh which the specifications vary frequently.

2.A pre-feeding mechanism is added and it improves the production efficiency.

3.Suit for different type of steel bar such as cold-drawn,hot-rolled round steel or hot-rolled bar.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

GWC-D

-

Weight (KG):

-

22000

-

Power (kW):

-

1600

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

green/customized

-

Wire diameter:

-

4-12mm

-

feeding method:

-

automatic/semi-automatic

-

discharging method:

-

automatic

-

Welding speed:

-

50-70 times/min

-

Type:

-

Other

Quick Details

-

Wire Diameter (mm):

-

5 - 12 mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

xinzhou

-

Model Number:

-

GWC-D

-

Weight (KG):

-

22000

-

Power (kW):

-

1600

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

green/customized

-

Wire diameter:

-

4-12mm

-

feeding method:

-

automatic/semi-automatic

-

discharging method:

-

automatic

-

Welding speed:

-

50-70 times/min

-

Type:

-

Other

Product Description

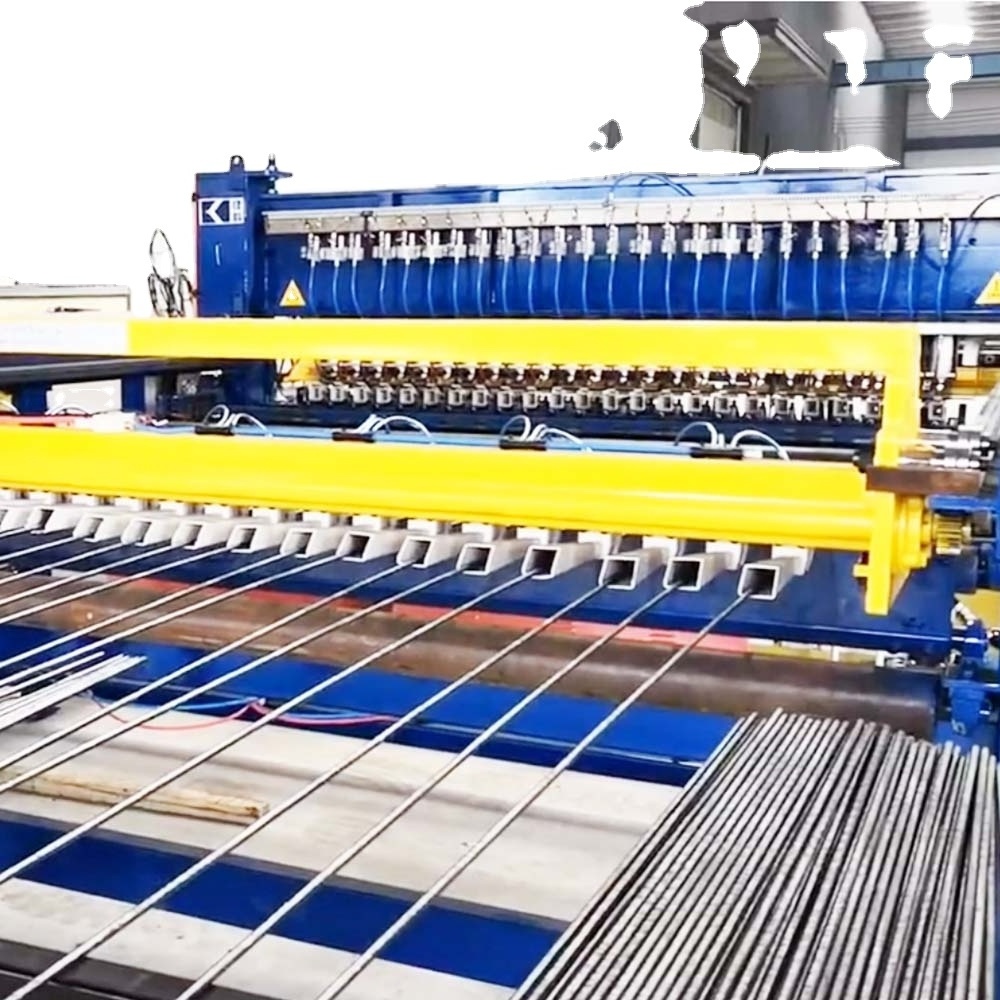

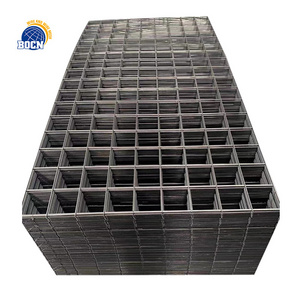

Welding Machines for the Production of

Reinforcement Mesh(4-12mm)

Gwc-B Automatic Wire Mesh Welding Production Line

.GWC-BW Automatic Bending Wire Mesh Welding Production Line

1.The mesh welding and bending are completed synchronously which is high production efficiency.

2.The host frame uses high-quality, thick steel plate which makes the structure more compactly and firmly.

3.Famous brand industrial control equipment are imported and the system has the advantage of highsecurity, intuitive operation,

4.standard mesh size, firm welding spots, and good consistency.

2.The host frame uses high-quality, thick steel plate which makes the structure more compactly and firmly.

3.Famous brand industrial control equipment are imported and the system has the advantage of highsecurity, intuitive operation,

4.standard mesh size, firm welding spots, and good consistency.

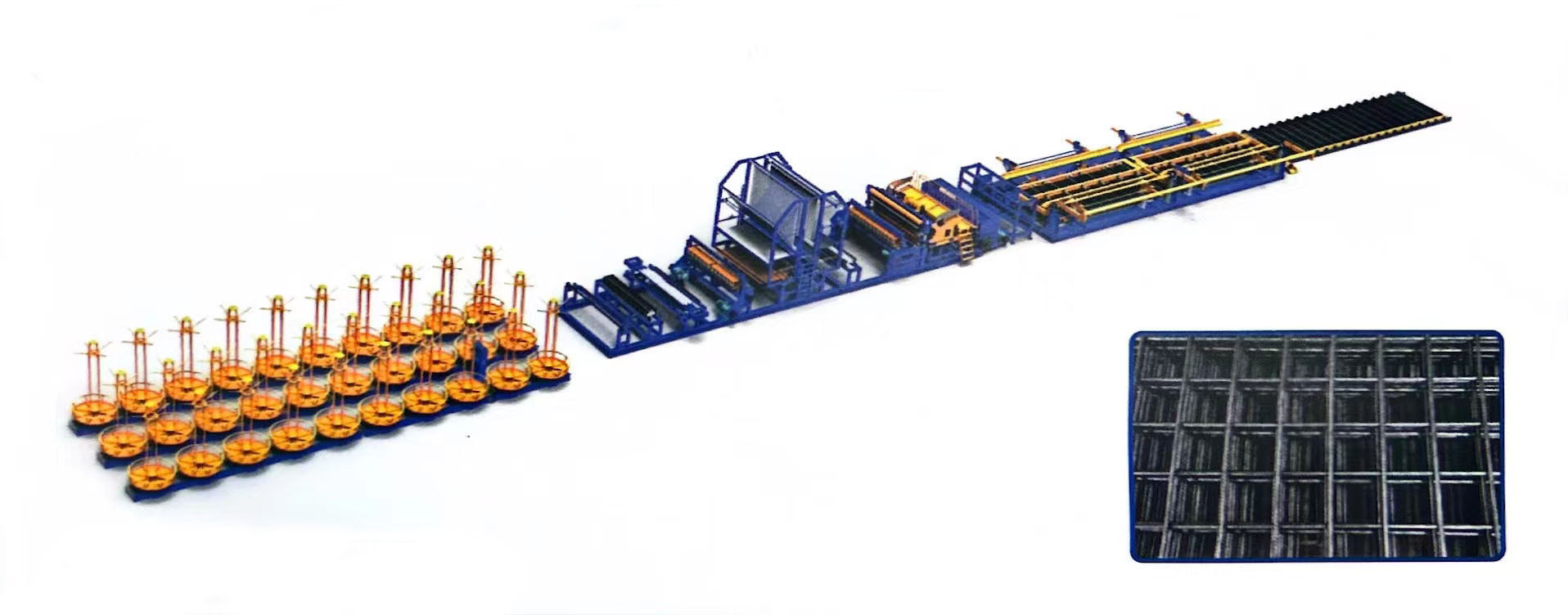

GWC-C Fully-automatic Wire Mesh Welding Production Line

1.This series is suitable for producing same specification and massive batch mesh. It has straightening mechanism for each line wire, the production efficiency and automation degree are high.

2.It is a fully-automatic mesh welding device for welding mesh after the round steel coils(cold-drawn or hot-rolled steel) are processed automatically.

2.It is a fully-automatic mesh welding device for welding mesh after the round steel coils(cold-drawn or hot-rolled steel) are processed automatically.

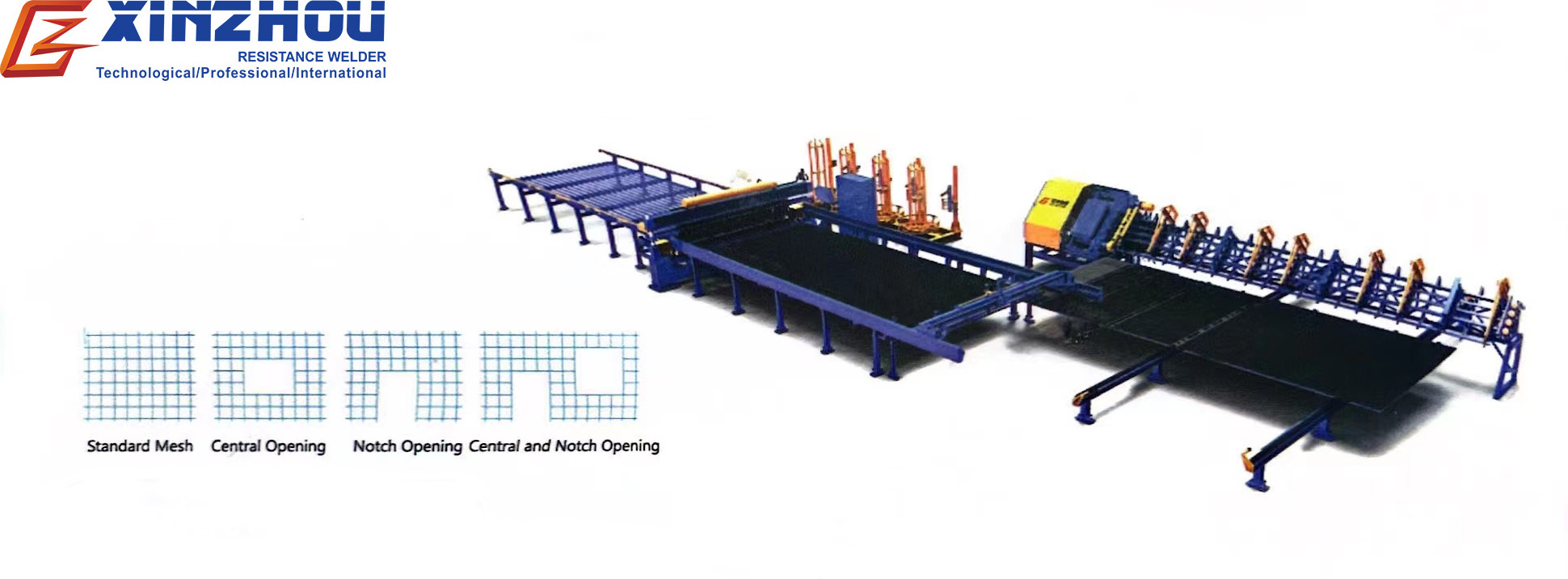

GWC-DR Flexible Wire Mesh Welding Production Line

a full-automatic wire mesh production line developedindependenuy oy ourconmpunyr oug the advanced technology in China and abroad.

With high degree of automation, built-in production flow control system can program automatically according CAD files. It can be used to weld many materials with wide adaptability, such as hot-rolled ribbed bar, cold-rolled ribbed bar, cold-rolled

plain bar etc.

With high degree of automation, built-in production flow control system can program automatically according CAD files. It can be used to weld many materials with wide adaptability, such as hot-rolled ribbed bar, cold-rolled ribbed bar, cold-rolled

plain bar etc.

Construction Industry-Reinforced concrete

Product Paramenters

|

Product Name

|

Fully Automatic Wire Mesh Welding Line

|

Style

|

GWC-3200-C

|

|

The power supply

|

380V 50Hz

|

The power phase number

|

3 phase 4 wire

|

|

Load duration

|

20%

|

Air pressure

|

0.6-0.8MPa

|

|

Coolant flow

|

40-60L/min

|

Coolant temperature

|

≤30℃

|

|

Voltage

|

3p 380V

|

Longitudinal spacing

|

50mm(increasing by 50)

|

|

Maximum welding capacity

|

Φ6+Φ8

|

duty cylce

|

20%

|

|

Horizontal spacing

|

≥25mm Unlimited adjustable

|

Steel bar diameter

|

Ø6-Ø8

|

|

Feeding way

|

Longitudinal bar plate material, horizontal bar straight

|

Discharging way

|

Unloading machine unloading

|

|

Maximum welding speed

|

95 rows/min (50 intervals)

|

Rated power

|

4 x150KVA

|

Recommend Products

Other Welding Machines for the Production of Industrial Mesh and Wire Fence(3-12mm)

Company Introduction

Ningbo Xinzhou Welding Equipment Co., Ltd. was founded in 1998, is a company mainly engaged in researching, designing, manufacturing and selling automation welding equipment, which is also a national high-new tech enterprises in China.

Its products are widely used in home appliances,hardware, auto parts production, petrochemical, liquid packaging, nuclear power station,hydropower station, steel structure platform, expressway, high-speed railway, rail transit and other large-scale infrastructure construction and precast constructions. With excellent quality and perfect service, the company has been widely recognized and unanimously praised by customers, products sell well in more than 30 countries and regions, and cooperate with a number of well-known enterprises to establish a long-term strategic partnership.

Exhibition

Certificate

Certificate of compiance

qualty management syatem

factory production control

Packing&Shipping

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes,we can provide good after-sale and fast delivery.

Q4: What is the price of your machine?

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us

thefollowing information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical

proposal and price for you.

Q5: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra

cost.

Q6: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty

period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new

parts, we will send engineer to your factory to help fixing the machine.

Q7: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q8: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you

need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the

machine.

Q9: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

Technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more

detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the

manufacturing process.

Q10: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide

you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,

visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us

thefollowing information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical

proposal and price for you.

Q5: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra

cost.

Q6: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty

period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new

parts, we will send engineer to your factory to help fixing the machine.

Q7: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q8: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you

need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the

machine.

Q9: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

Technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more

detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the

manufacturing process.

Q10: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide

you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,

visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Hot Searches