- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KeHua, KeHua

-

Model Number:

-

ZKBM

-

Certification:

-

ISO, CE

-

Color:

-

As Required

-

Application:

-

Many Raw Materials

-

Service:

-

Intime and Considerate

-

Guarantee:

-

One Year

-

Operation:

-

Easy and Simple

-

Installation:

-

Engineer Guide

-

Payment:

-

T/T, L/C

Quick Details

-

Production Capacity:

-

1-30T/h

-

Power:

-

45

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KeHua, KeHua

-

Model Number:

-

ZKBM

-

Certification:

-

ISO, CE

-

Color:

-

As Required

-

Application:

-

Many Raw Materials

-

Service:

-

Intime and Considerate

-

Guarantee:

-

One Year

-

Operation:

-

Easy and Simple

-

Installation:

-

Engineer Guide

-

Payment:

-

T/T, L/C

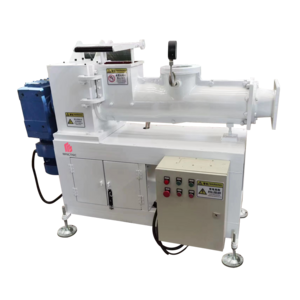

Briquette MakingMachine

Skype: zkbm1998

Brief Introduction of Briquette Making Machine

1. ZhengZhou KeHua Briquette Making Machine is mainly used for pressing powder material.

2.Such as, coal powder, charcoal powder, metallic powder, iron scale, iron sludge, precipitator dust, iron

concentrate, the final production can be press into ball, oval pillow and egg shapes, etc.

3. Briquette Making Machine mainly used in the pulverized coal forming; Dry powder molding; The desulfurization

gypsum molding; Coke powder molding; Iron ore and all kinds of metal powder molding, etc.

Feature of Briquette Making Machine

1. High profit and low cost in raw material

2. Increase the calorific value per unit volume after briquetting

3. Energy saving, friendly-environment, Low-consumption

4. No chemical additives, no smell, no smoke

5. Easy to transport and store as densities product

Working Principle of B riquette Making M achine:

The pressure throughout a closed system is constant. One part of the system is a piston acting as a pump,

with modest mechanical force acting on a small crosssectional area; the other part is a piston with a larger

area which generates a correspondingly large mechanical force. Only smalldiameter tubing (which more

easily resists pressure) is needed if the pump is separated from the press cylinder.When the pressure on

the press cylinder is released (the fluid returning to a reservoir), the force created in the press is reduced

to a low value (which depends on the friction of the cylinder's seals. )

Main Technical Paramaters

|

Model |

Roll Diameter (MM) |

Capacity (T/H) |

Powder (KW) |

|

ZKBM 290 |

290 |

1-3 |

5.5 |

|

ZKBM 360 |

360 |

4-6 |

11-15 |

|

ZKBM 430 |

430 |

6-8 |

18.5 |

|

ZKBM 500 |

500 |

7-9 |

18.5-55 |

|

ZKBM 500H |

500 |

7-9 |

20.7-57.2 |

|

ZKBM 650 |

650 |

10-15 |

37-45 |

|

ZKBM 650H |

650 |

10-15 |

39.2-47.2 |

|

ZKBM 750 |

750 |

15-20 |

75-110 |

|

ZKBM 750H |

750 |

15-20 |

78-113 |

|

ZKBM 850 |

850 |

20-25 |

90-110 |

|

ZKBM 850H |

850 |

20-25 |

93-113 |

|

ZKBM 1000 |

1000 |

25-30 |

90-132 |

|

ZKBM 1000H |

1000 |

25-30 |

93-135 |