Hardness:

HRC55-62 °

Speed:

G2.5 20000RPM/r

Function:

High precision and high speed

Application environment:

milling, drilling, reaming, tapping can be applied

Note: PHC is a hydraulic tool holder, which also has other names such as SASL/HDC

PHC = HDC = SASL

PHC = HDC = SASL

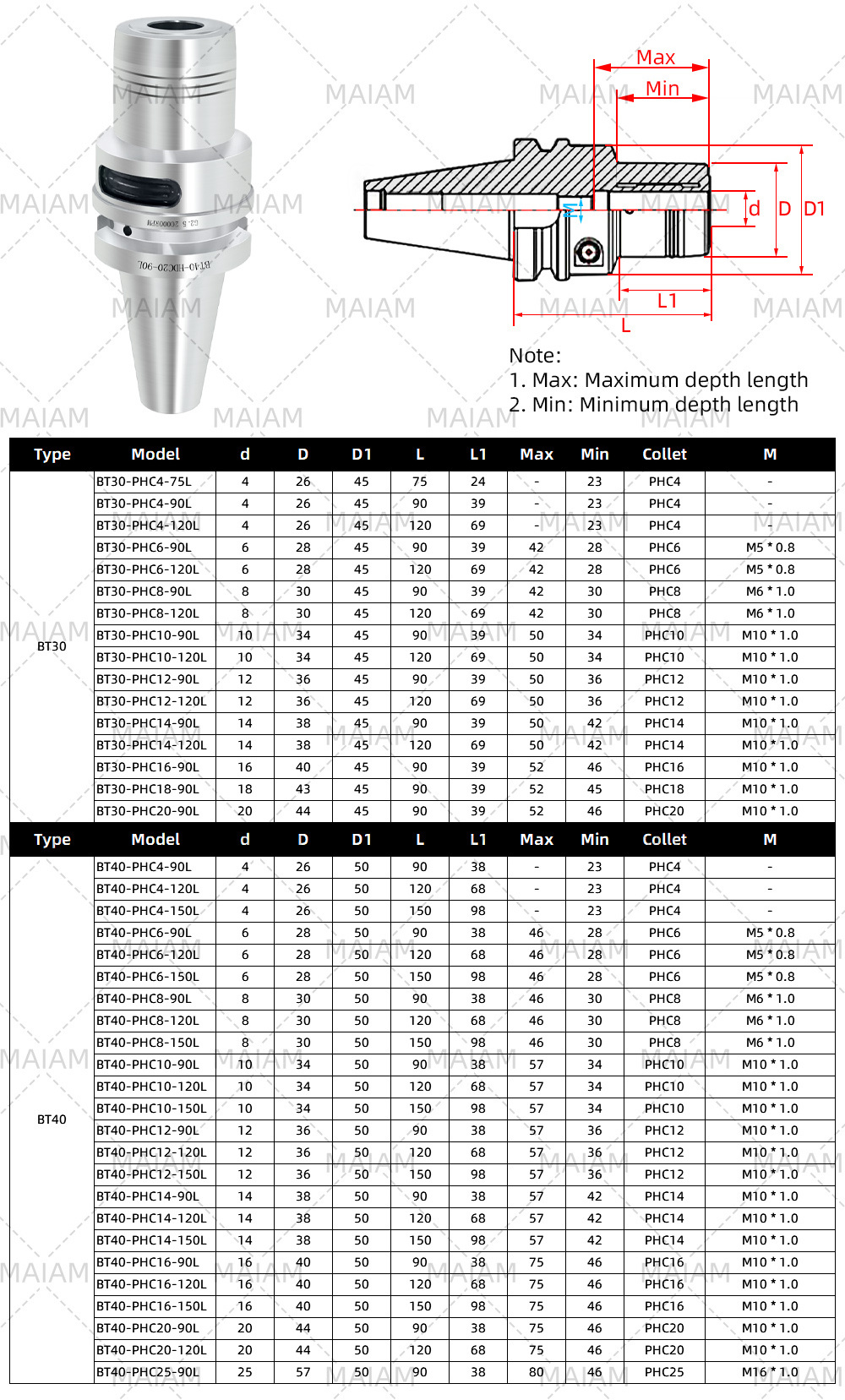

(Note: For more parameters, please contact for consultation)