- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4700*2930*3200

-

Power (kW):

-

9.73

-

Weight (KG):

-

1500 KG

-

Product Name:

-

Continuous Pre Expander Machine Eps Polystyrene

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Application:

-

EPS Material Expanding Foaming

-

Material:

-

steel structure

-

Operation:

-

PLC and touch screen

-

Color:

-

Selectable

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Joseph

-

Machine Type:

-

EPS

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4700*2930*3200

-

Power (kW):

-

9.73

-

Weight (KG):

-

1500 KG

-

Product Name:

-

Continuous Pre Expander Machine Eps Polystyrene

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Application:

-

EPS Material Expanding Foaming

-

Material:

-

steel structure

-

Operation:

-

PLC and touch screen

-

Color:

-

Selectable

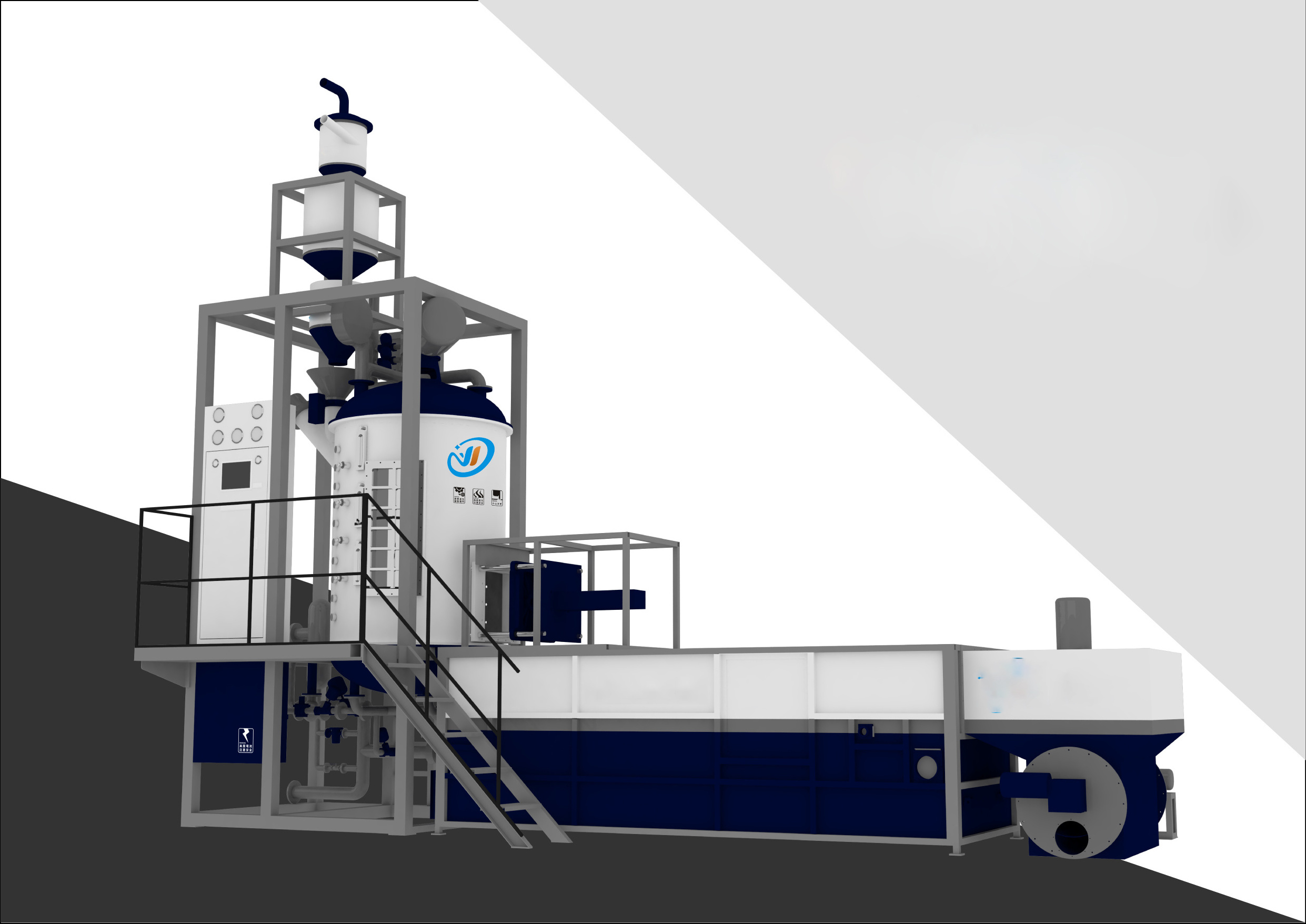

Products Description

Auto EPS Continous Pre-expander

turns eps raw material (expanded polystyrene) to big and light foam beads through steam heating. With PLC, touch screen and weighing system to realize full automatic production for feeding, heating and ejecting foam beads.

1.Pictures of Continuous Pre Expander Machine Eps Polystyrene

2.Technical Data of Continuous Pre Expander Machine Eps Polystyrene

|

Item

|

|

PSJ70

|

PSJ90

|

PSJ120

|

|

|

Expansion Chamber

|

Diameter

|

φ700mm

|

φ900mm

|

φ1200mm

|

|

|

|

Volume

|

0.6m³

|

1.2m³

|

2.2m³

|

|

|

|

Useable Volume

|

0.4m³

|

0.8m³

|

1.5m³

|

|

|

Steam

|

Entry

|

DN20

|

DN25

|

DN40

|

|

|

|

Consumption

|

80-100kg/h

|

100-150kg/h

|

150-200kg/h

|

|

|

|

Pressue

|

0.6-0.8MPa

|

0.6-0.8MPa

|

0.6-0.8MPa

|

|

|

Compressed Air

|

Entry

|

DN15

|

DN20

|

DN20

|

|

|

|

Pressure

|

0.6-0.8MPa

|

0.6-0.8MPa

|

0.6-0.8MPa

|

|

|

Drainage

|

Condensate

|

φ20mm

|

φ20mm

|

φ20mm

|

|

|

Throughput

|

15g/l

|

100kg/h

|

150kg/h

|

250kg/h

|

|

|

|

20g/l

|

120kg/h

|

200kg/h

|

300kg/h

|

|

|

|

25g/l

|

150kg/h

|

250kg/h

|

410kg/h

|

|

|

|

30g/l

|

200kg/h

|

300kg/h

|

500kg/h

|

|

|

Material Conveying Line

|

|

φ150mm

|

φ150mm

|

φ150mm

|

|

|

Power

|

|

8.93kW

|

9.73kW

|

14.83kW

|

|

|

Density

|

First expansion

|

12-30g/L

|

12-30 g/L

|

14-30 g/L

|

|

|

|

Second expansion

|

8-11g/L

|

8-11g/L

|

8-13g/L

|

|

|

Density Tolerance

|

|

±2%

|

±2%

|

±3%

|

|

|

Outside Dimensions

|

L×W×H

|

4700×2660×2600mm

|

4700*2930*3200mm

|

4905*4655*3250mm

|

|

|

Weight

|

|

1300kg

|

1500kg

|

1800kg

|

|

|

Room Height Required

|

|

3000mm

|

3000mm

|

3000mm

|

|

3.Features of Continuous Pre Expander Machine Eps Polystyrene

1.Feeding, expander, filtrating, crushing, transport to silos automatically

2.With first and second expansion ,the first time filling adopt frequency conversion feeding device,guarantee the stability of feeding

3.Uniform foaming ,foam density range is 6-35g/l

4.Material barrel inside and outside ,fluidized bed dryer made of stainless steel ,in order to maintain the durable use and stable performance

5.Electrical protection device

6.Adopt Japanese reducing valve

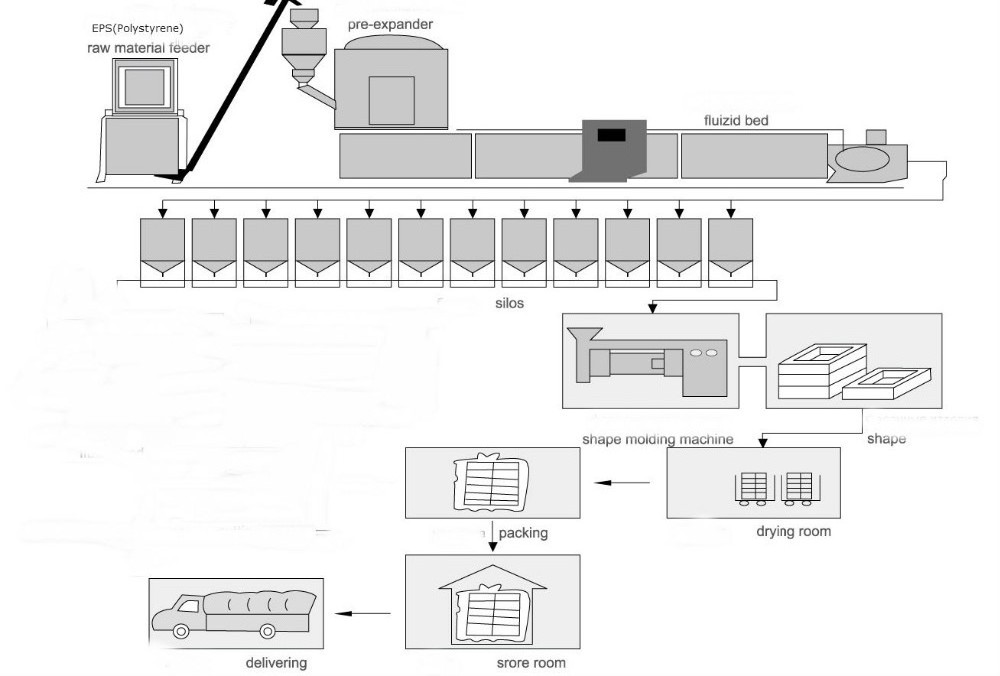

4.Application of Continuous Pre Expander Machine Eps Polystyrene

Hot Searches