- Product Details

- {{item.text}}

Quick Details

-

Diameter of top chord bar:

-

6~14mm

-

Diameter of botton chord bar:

-

5~14mm

-

Diameter of web bar:

-

4~8mm

-

Straight leg truss overall height:

-

(F+H)=70~350mm

-

Web bar pitch:

-

T=195~205 mm

-

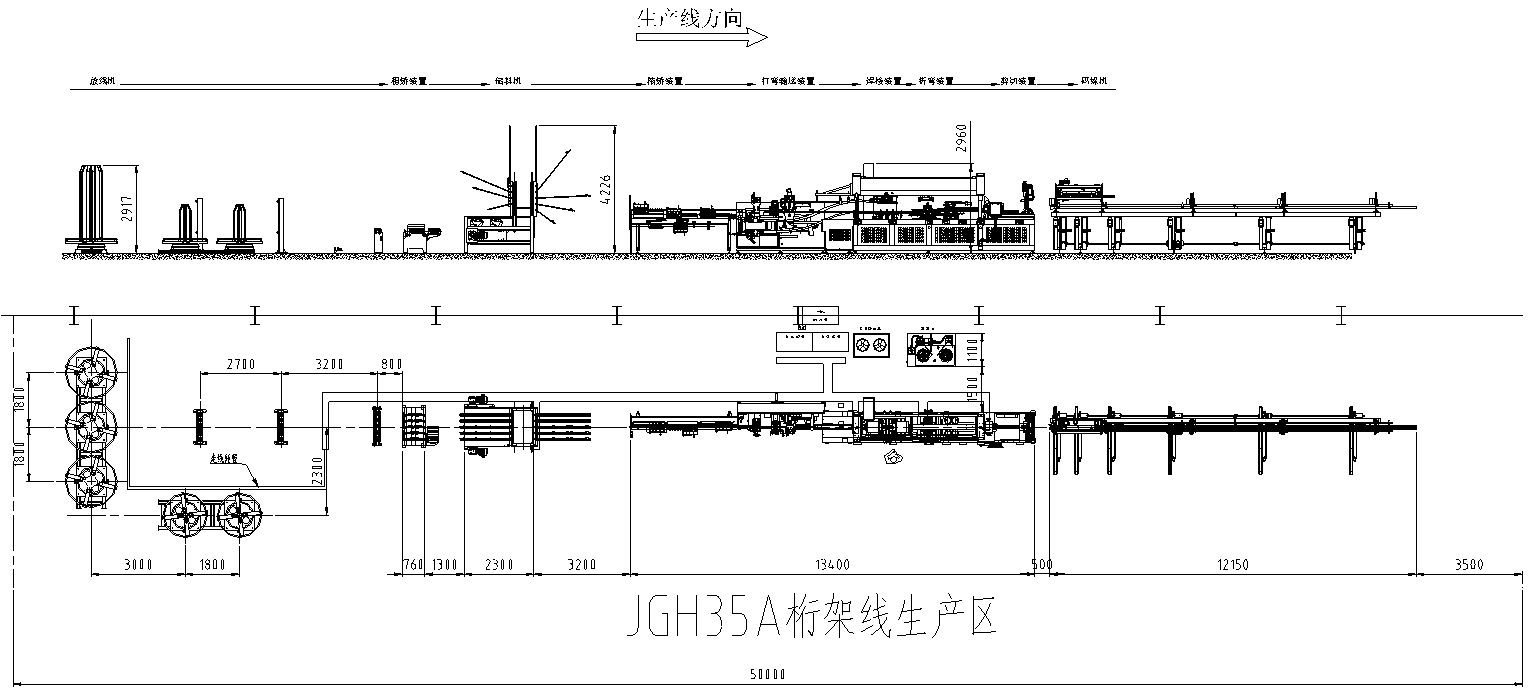

Production line space size:

-

45000*5000*4500 mm

-

input power:

-

380V/50 Hz

-

MOQ:

-

1 Set

-

Temperature:

-

-5~45 ℃

-

Equipment motor installed power:

-

80 kW

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OBM

-

Weight (KG):

-

6000

-

Diameter of top chord bar:

-

6~14mm

-

Diameter of botton chord bar:

-

5~14mm

-

Diameter of web bar:

-

4~8mm

-

Straight leg truss overall height:

-

(F+H)=70~350mm

-

Web bar pitch:

-

T=195~205 mm

-

Production line space size:

-

45000*5000*4500 mm

-

input power:

-

380V/50 Hz

-

MOQ:

-

1 Set

-

Temperature:

-

-5~45 ℃

-

Equipment motor installed power:

-

80 kW

Product Paramenters

|

Diameter of top chord steel bar

|

φ6~φ14mm

|

|

Bottom chord steel bar diameter

|

φ5~φ14mm

|

|

Diameter of web bar

|

φ4~φ8mm

|

|

Total height of straight truss

|

(F+H)=70~350mm;

|

|

Height from bottom chord to bottom

|

bent truss C=15~30mm;

|

|

|

Straight leg truss F=0~30mm (F value should satisfy 70≤(F+H)≤350mm)

|

|

|

Plane truss H=70~350 mm

|

|

Bottom width of triangular truss

|

curved truss A=135~140mm; straight truss b=60, 80mm

|

|

Triangular truss bent foot width

|

B=30mm

|

|

NO.

|

Equipment or component name

|

|

1.

|

5 sets of rebar charging

|

|

2.

|

Pre-straightening device 1 set

|

|

3.

|

1 set of broken rib detection device

|

|

4.

|

Rebar storage device 1 set

|

|

5.

|

1 set of steel bar fine straightening device, horizontal and vertical two-way straightening wheel set

|

|

6.

|

1 set of twist correction device for winding bars

|

|

7.

|

Abdominal bar bending device 1 set of mechanical arm bending

|

|

8.

|

1 set of steel bar fixed-length front pinch device synchronized with the rear pinch

|

|

9.

|

1 set of rear pinch device for rebar fixed length, synchronized with the front pinch

|

|

10.

|

1 set of welding positioning device for web bar rib with adjustable pitch

|

|

11.

|

1 set of steel welding host, frequency control

|

|

12.

|

1 set of bending device for the bottom of the web

|

|

13.

|

Rebar cutting device 1 hydraulic

|

|

14.

|

Palletizing device 1 set 12m/6m, default 12m

|

|

15.

|

Welding system 1 set variable frequency power supply, 200kVA×4

|

|

16.

|

Electronic control system 1 set

|

|

17.

|

Hydraulic system 1 set

|

|

18.

|

Pneumatic system 1 set

|

|

19.

|

Cooling system 1 set

|

Details Images

Manufacturing Technique

Raw material requirements

The upper and lower chords are made of disc-shaped threaded steel bars, which meet the standard requirements of GB14981-2004 "Hot Rolled Wire Rod Size, Shape, Weight and Allowable Deviation";

The web bar is made of light disc bar material, which meets the standard requirements of GBT 14981-2004 "Hot Rolled Wire Rod Size, Shape, Weight and Allowable Deviation".

The maximum speed of the production line (test sample TD3-100):

The maximum production speed of conventional bent truss: 15-20 m/min

Total equipment power:

Welding power source: using the latest AC frequency conversion technology, the installed capacity of the transformer is 200kW x 4 units

Electric power for welding system production: 250 kVA (variable frequency welding power source)

Equipment motor installed power: 80 kW

3000 type chiller: ≈ 13 kW (outsourcing equipment, subject to delivery)

The actual normal production power consumption of the production line: about 60kW (motor)

Input power: 380V/50 Hz three-phase AC

Ambient temperature: -5~45 ℃

Truss length: 2 to 6 m or 2 to 12 m (optional, default 2 to 12 m)

Water-gas-liquid parameters:

Cooling water: ≥100 L/min (On the premise that the cooling effect of the equipment can ensure the normal circulation of the cooling water, the cooling water must be pure water, and antifreeze must be added when it is below zero)

Compressed air source: ≥0.6 MPa

Compressed air flow: ≥1 m3/min

Hydraulic pressure: 16 MPa

Production line space size:

Length×width×height: ≈45000×5000×4500 mm

Why Choose Us

Certifications

FAQ

1、Does one machine can only produce one size?

Not exactly, it depends on the machine.

2、Do you have after sales support?

Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3、How to visit your company?

We can pick you up from Shanghai or Hangzhou airport. Or railway station Shaoxing North.

4、What can you do if the machine broken?

Our machine's warranty period is 12months. if the broken parts can't repair, we can send the new parts replace the broken

parts, but you need pay the express cost by yourself. if after warranty period, we can through negotiation for solving the

problems, and we supply the technical support for the whole life of the equipment.

5、Can you be responsible for transport?

Yes,please tell us the destination port or address. we have rich experience in transport.

6、You are trade company or factory?

We are Manufacturer.

7、Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our machine could use more than 20 years without any problem.

8、Do you have overseas engineers?

Yes, we not only provide overseas engineers, but also provide technical training.

9、Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide. We are professional sheet metal

forming machine designer and manufacturer.

2、Do you have after sales support?

Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3、How to visit your company?

We can pick you up from Shanghai or Hangzhou airport. Or railway station Shaoxing North.

4、What can you do if the machine broken?

Our machine's warranty period is 12months. if the broken parts can't repair, we can send the new parts replace the broken

parts, but you need pay the express cost by yourself. if after warranty period, we can through negotiation for solving the

problems, and we supply the technical support for the whole life of the equipment.

5、Can you be responsible for transport?

Yes,please tell us the destination port or address. we have rich experience in transport.

6、You are trade company or factory?

We are Manufacturer.

7、Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our machine could use more than 20 years without any problem.

8、Do you have overseas engineers?

Yes, we not only provide overseas engineers, but also provide technical training.

9、Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide. We are professional sheet metal

forming machine designer and manufacturer.

Hot Searches