- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8000*1000*1300mm

-

Weight:

-

4500 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

Other

-

Product name:

-

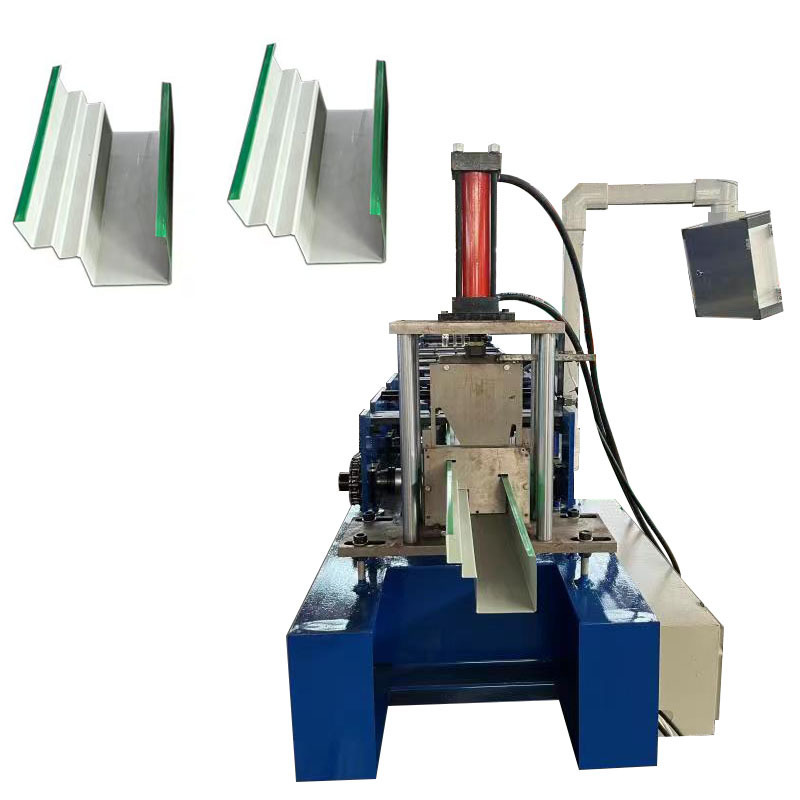

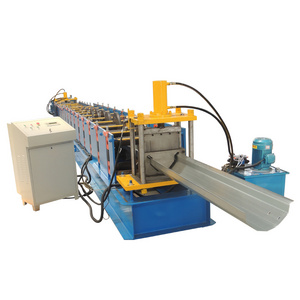

K style seamless metal rain gutter Ogee Gutters roll forming machine

-

Usage:

-

Roof gutter

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12 Mould Steel

-

Control system:

-

PLC(imported Brand)

Quick Details

-

Type:

-

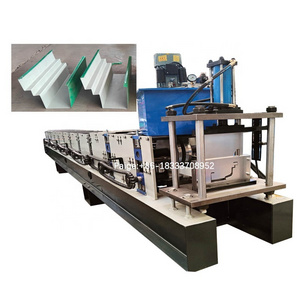

Tile Forming Machine

-

Tile Type:

-

K style gutter

-

Production Capacity:

-

15-20m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8000*1000*1300mm

-

Weight:

-

4500 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

Other

-

Product name:

-

K style seamless metal rain gutter Ogee Gutters roll forming machine

-

Usage:

-

Roof gutter

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12 Mould Steel

-

Control system:

-

PLC(imported Brand)

K style seamless metal rain gutter Ogee Gutters roll forming machine for residential houses

K style seamless metal rain gutter Ogee Gutters roll forming machine for residential houses

K-Style gutters, also known as Ogee Gutters are the standard in the gutter industry.

Galvalume consists of steel sheets coated with aluminum and zinc, resulting in a strong, durable metal with proven long term corrosion resistance, normally used on metal roofs. Galvalume also has a more neutral appeal without disturbing the balance of the home’s aesthetic, which makes it an ideal choice, instead of colors. Many find it to be more modern and refined than other gutter systems.

we offer along with all accessories needed for your gutter system.

K style seamless metal rain gutter Ogee Gutters roll forming machine

working flow

K style seamless metal rain gutter Ogee Gutters roll forming machine

parameter

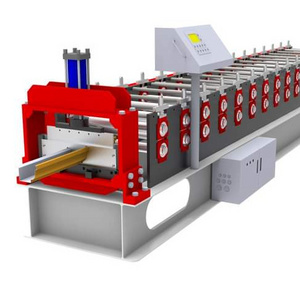

|

Raw material

|

GI/GL/PPGI/PPGL/Aluminum coils

|

|

Material thickness

|

0.3-0.8mm

|

|

Voltage

|

220V 60Hz 3 Phase or as your request

|

|

Main power

|

5.5Kw

|

|

Hydraulic power

|

4Kw

|

|

Working speed

|

18-20m/m

|

|

Control system

|

PLC delta or brand as your request

|

|

Machine main structure

|

350H beams, side plate 18mm

|

|

Roller station

|

14-16 rows depend on the profile drawing

|

|

Roller material

|

45# forming steel with chromium plate

|

|

Shaft

|

¢70mm(Solid shafts)

|

|

Cutting blade material

|

Cr12,

Quenched treatment 58℃-60℃

|

|

Machine weight

|

4000kg

|

|

Machine size

|

6.5*1.35*1.2m

|

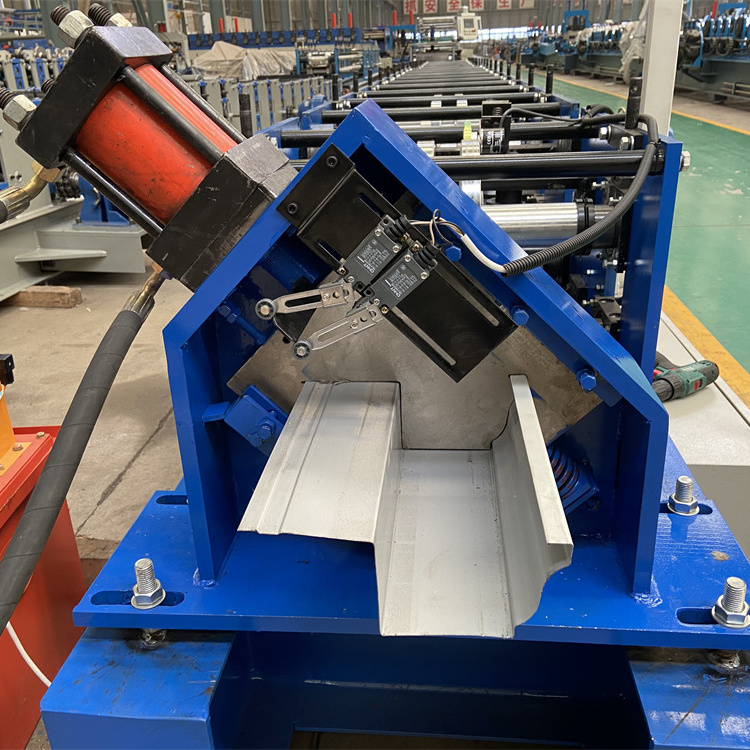

1)The cutter construction and the guides on the cutter must be strong enough material to withstand sheet metal cutting continuously

2)Profile blades material Cr12MOV normally for cutting stainless steel, best hardened with a thickness of 20 mm. Nearly no requiring grinding, save maintenance cost.

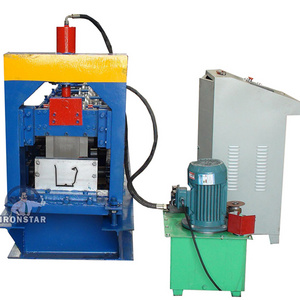

1)The electronic components, the PLC, Inverter, touch screen can be Delta, Mitsubishi, or brand as you request

2)

Optional 360°rotating console , that greatly saves manpower.

Main forming

Machine rollers all be high grade 45# steel(plated chrome on surface), the roller precision process by our own CNC machine, which can control the roller quality and precision, ensure the R panel size accuracy and shape beautiful.

Feeding platform

Features: split uniform material, two-wheel fine adjustment function,do not destroy the painting of the raw material

Advantages: stable production, balanced left and right, consistent batch,prevent the feeding deviation

Optional devices

automatic decoiler & automatic stacker

Other panel

Other Products

Hot Searches