- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Green Valley

-

Dimension(L*W*H):

-

1820*1000*1150mm

-

Weight:

-

400 kg

-

Product name:

-

port Running Track Surface Spraying Machine

-

Function:

-

Paint Cement

-

Usage:

-

Spray Wall Ceiling Machine

-

Type:

-

Electric

-

After-sales Service Provided:

-

Video Technical Support

-

Power Source:

-

Electeic

-

Advantage:

-

Reinforced structural parts Energy saving Long lifetime

-

SIZE:

-

1820*1000*1150mm

-

MOQ:

-

1 Set

-

Brand:

-

Green Valley

Quick Details

-

Max. vertical conveying distance:

-

10M

-

Max. horizontal conveying distance:

-

10M

-

Hopper Capacity:

-

120

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Green Valley

-

Dimension(L*W*H):

-

1820*1000*1150mm

-

Weight:

-

400 kg

-

Product name:

-

port Running Track Surface Spraying Machine

-

Function:

-

Paint Cement

-

Usage:

-

Spray Wall Ceiling Machine

-

Type:

-

Electric

-

After-sales Service Provided:

-

Video Technical Support

-

Power Source:

-

Electeic

-

Advantage:

-

Reinforced structural parts Energy saving Long lifetime

-

SIZE:

-

1820*1000*1150mm

-

MOQ:

-

1 Set

-

Brand:

-

Green Valley

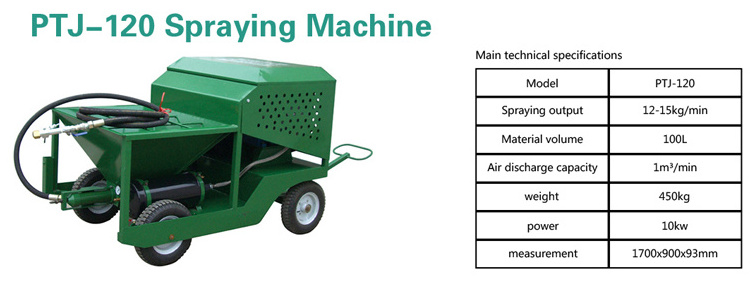

Products Description

|

Product Name

|

PTJ-120 Spraying Machine Cost Running Track Sprayer Machine

|

|

SprayName

|

High Quality Wheel PTJ-120 Rubber Spraying Machine For Running

|

|

Model

|

PTJ-120/PTJ-60

|

|

Brand

|

Green-Valley

|

|

Voltage

|

220V/380V

|

|

Power(W)

|

10.5 kw

|

|

Certification

|

CE

|

|

SizeDimension(L*W*H)

|

1600*1000*1100mm

|

|

Spray output capacity

|

12-15kg/min

|

|

Effective Hopper volume

|

120L

|

|

Machine Weight

|

5000 kg

|

|

Our Service

|

Welcome to consultation

|

Specifications

|

NO

|

Fault

|

Cause

|

|

Ⅰ

|

The air compressor no run

|

1. power is not connection

2.power phase connection opposite 3.contactor is not soak join 4. thermal relay is not reset 5. oil temperature is too high ,the oil compressor protect itself 6. machine's stop time short |

|

Ⅱ

|

Press too low

|

1. Press oil too litter

2. the air compressor too dirty 3. the air compressor must clean 4. servo-valve is stopped up 5. the air filter is stopped up |

|

Ⅲ

|

The air blow too least

|

1. press oil too litter

2. air pipe is stopped 3. the spraying gun the air outlet pipe stopped |

|

Ⅳ

|

Spraying material air compressor will not be atomized consistently good

|

1. air pressure too low

2. air quantity is not enough 3. the air compressor pressure is not match with feeding speed |

Cleaning and maintenance of machine

1.

Whenever missing spraying, if the breakdown time too short, it can put the spraying gun put on the bailer cover's the rifle rack, let itself auto-cycle.

2.When the spraying finished each time , should put in the bailer the rest of material spraying, then add up enough industrial alcohol, in the bailer put the equipment carry on cleaning itself(at least twice).it mustn't adopt toluol or dim ethyl benzene make cleaning, in order to avoid to damage the feeding pipe and pump stator's service life.

3.

When the hose carry on cleaning itself after, should put the pump's screw axis, spraying nozzle dismount, and put the rotor spin out in the stator, use industrial alcohol clean these details, and put the rotor surface coat the seed oil finished replace spin in stator ,then spraying next time using.

4.

Part of the air compressor see the air compressor constructions.

Certifications

FAQ

Hot Searches