- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Automatic Grade:

-

Full Automatic

-

Driven Type:

-

Electric and pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZXSMART

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1200 KG

-

After sales service 1:

-

Overseas service

-

After sales service 2:

-

24 Hour online service

Quick Details

-

Machinery Capacity:

-

4000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Other, Milk, Water, Oil, Juice, Daily Chemical Liquid

-

Filling Accuracy:

-

±1%

-

Automatic Grade:

-

Full Automatic

-

Driven Type:

-

Electric and pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZXSMART

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1200 KG

-

After sales service 1:

-

Overseas service

-

After sales service 2:

-

24 Hour online service

Product Description

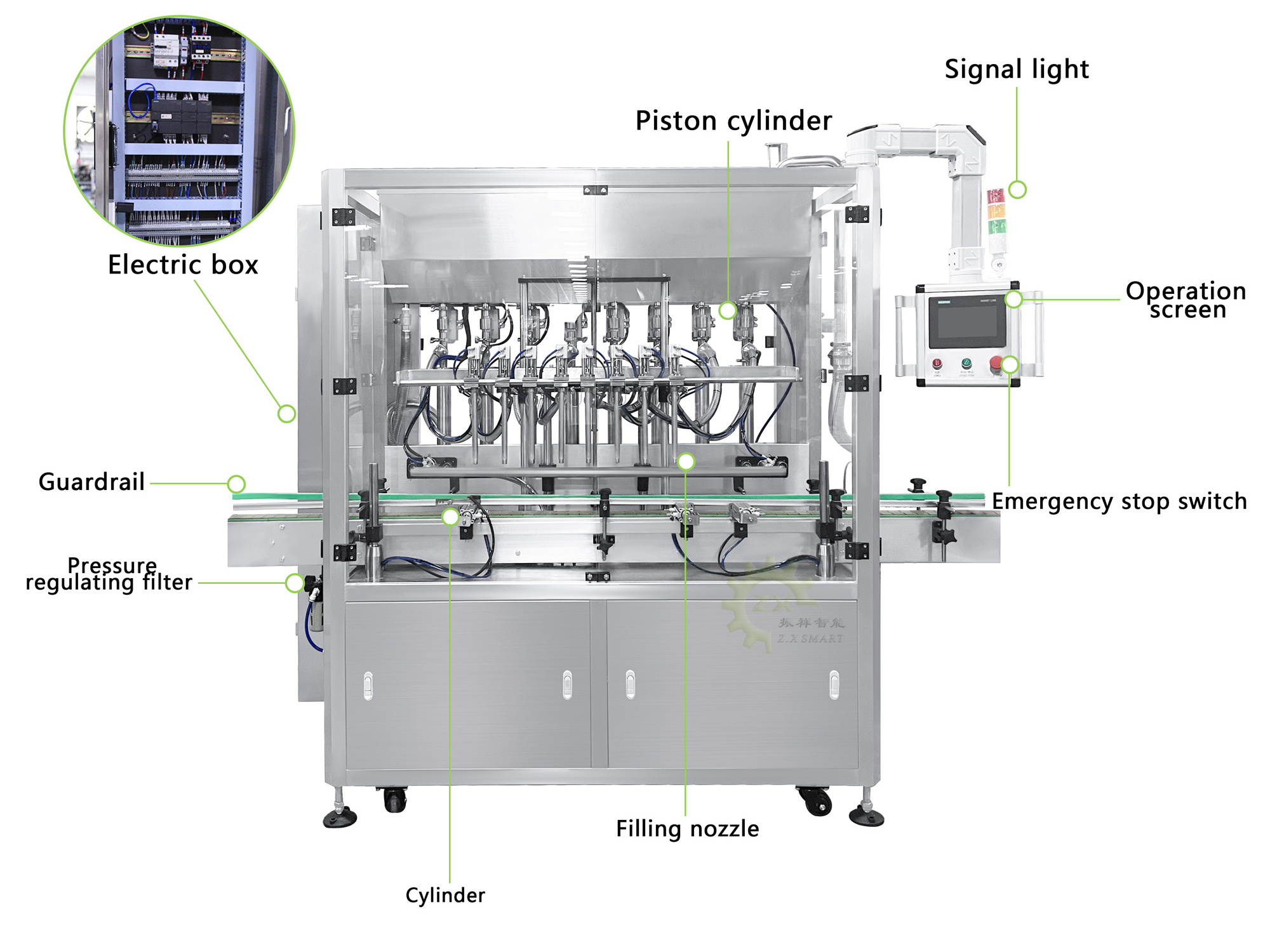

Automatic Detergent Hand Wash Liquid Soap Shower Gel Body Cream Lotion Shampoo Filling Machine

Description:

This production line can fill liquid, cap bottle lids and label stickers automatically, it is the ideal choice for producing liquid food,cosmetics or daily chemical products. The automated production can help you to reduce production cost and error, improveworking efficiency and production quality.

It can be applied to a variety of bottle types with high production efficiency.

Filling Machine

|

Machine Model

|

ZX-MHFM

|

|

|

Voltage

|

110-60HZ, 220V-50HZ

|

|

|

Power

|

3000W

|

|

|

Air Consumption

|

0.4-0.6MPa

|

|

|

Filling Accuracy

|

±1%

|

|

|

Working Speed

|

30-70 bttles/min(based on material)

|

|

|

Size Of Filing Nozzle

|

φ 8-20mm

|

|

|

Size Of Air Compressor Connector

|

φ10mm

|

|

|

Filling Range

|

10-100ML/30-300ML/50-500ML/100-1000ML/500-3000ML/1000-5000ML

|

|

|

Machine Size

|

About 2500*2000*1850mm(L*W*H)

|

|

|

Packaging Size

|

About 2650*2100*1950mm

|

|

|

Net weight/Gross weight

|

About 549.5kg/650.5kg

|

|

|

|

||

Capping Machine

|

Machine Model

|

ZX-SHCM

|

|

|

Voltage

|

220V 60HZ

|

|

|

Capping Speed

|

About 20-40 bottles/min

|

|

|

Bottle height

|

45-320mm

|

|

|

Bottle diameter

|

23-100mm

|

|

|

Cap diameter

|

19-55mm

|

|

|

Capping Torsion

|

4-9kgf/cm

|

|

|

Air pressure

|

0.4-0.6Mpa

|

|

|

Max power

|

1000W

|

|

|

|

||

Labeling Machine

|

Machine Model

|

ZX-RPLM

|

|

|

Power supply

|

AC220V 50Hz, 60Hz 1500W

|

|

|

Labeling capacity

|

25- 50PCS /min(depends on bottle size)

|

|

|

Labeling accuracy

|

±1.0mm

|

|

|

Suitable Botle Diameter

|

φ30-100mm

|

|

|

Label size

|

(L)15-200mm (H)15-150mm

|

|

|

Roll inside diameter

|

φ76mm

|

|

|

Roll outside diameter

|

φ350mm

|

|

|

Conveyor Size

|

1950(L)*100mm(W)

|

|

|

Machine size

|

About (L)2000*(W)1400*(H)1300(mm)

|

|

|

Packing size

|

About 2120*940*1500mm

|

|

|

|

||

Filling head

The 8 piston heads adopt an anti-drip design and can fill 8 bottles at the same time or 16 bottles

in a staggered position

. The production efficiency is greatly improved. The filling head is inserted into the bottle while filling to reduce bubbles. Each nozzle can be controlled individually.

Pneumatic valve, Air cylinder

The imported high-quality pneumatic valve uses the power of compressed air to push the valve to open and close, p

recise quantification

. The large cylinder ensures that the machine works stably and quickly, making the machine suitable for filling liquids with various viscosities.

Capping gripper

A capping gripper can realize the integrated operation of feeding the bottle cap and capping the bottle. There is no need to add a cap feeding machine for saving costs, and adjusting parameters according to your bottle cap to achieve complete automation.

Cap sorting machine

Just put a large number of bottle caps into the storage box, and the elevator lifting belt will automatically sort and send the bottle caps with only the correct side to the bottle feeding guide rail, which not only speeds up production speed and efficiency, but also saves labor costs.

Bottle clamping and labeling station

The rotating wheel will clamp the bottle and drive the bottle to rotate, so that the labeling wheel can label smoothly without any bubbles when the bottle reaches here. The labeling parameters can be changed according to the characteristics of the bottle or different labeling machines can be used.

Label fixing and sending station

The label sending station is driven by a high-quality servo motor, which delivers labels stably and accurately. Labeling is done only when there are bottles, and the label will not get struck when running

because it is well made and well designed.

Related Products

Hot Searches