- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Aite-300/500/800

-

Material:

-

Export Wooden Packing

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

7500 kg

-

Product name:

-

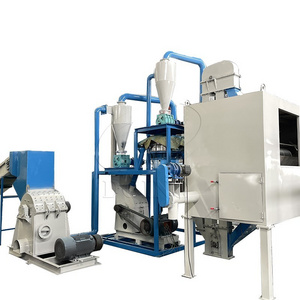

E-waste recycling equipment

-

Application:

-

Green Gnergy Solar panel Moudular Recycling

-

Suitable material:

-

Solar PV Panels, PV Modules, Solar Panels

-

After Warranty Service:

-

Field Maintenance

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Power(kw):

-

65/90/120

-

Usage:

-

Solar panel recycling machine

-

Voltage:

-

220 v/380 v

Quick Details

-

Production Capacity:

-

200-800 kg/h, 200-1000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Aite

-

Model Number:

-

Aite-300/500/800

-

Material:

-

Export Wooden Packing

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

7500 kg

-

Product name:

-

E-waste recycling equipment

-

Application:

-

Green Gnergy Solar panel Moudular Recycling

-

Suitable material:

-

Solar PV Panels, PV Modules, Solar Panels

-

After Warranty Service:

-

Field Maintenance

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Power(kw):

-

65/90/120

-

Usage:

-

Solar panel recycling machine

-

Voltage:

-

220 v/380 v

Product Overview

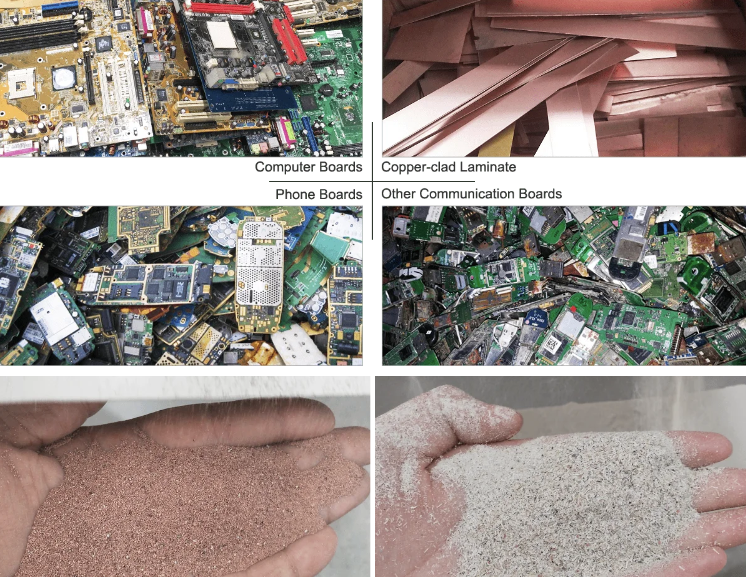

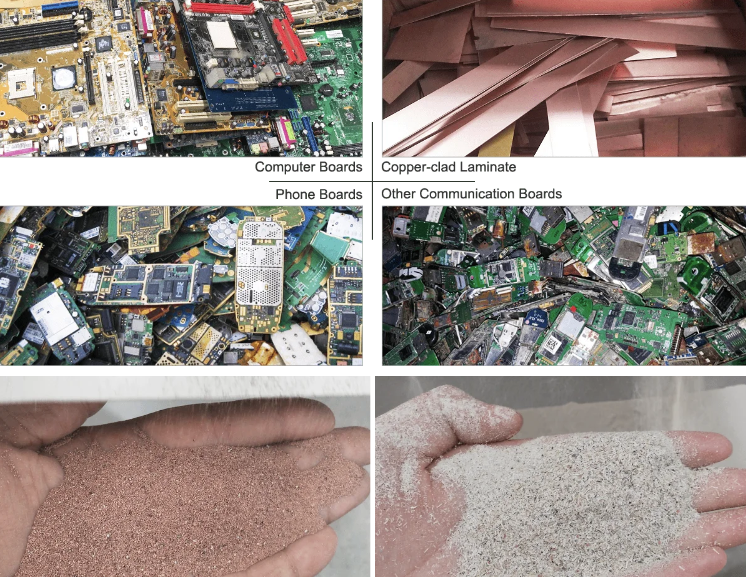

Computer Boards Recycling Waste PCB Motherboard Recovery Plant E Waste Recycling Machine For Sale

The surface of the PCB is coated with protective metal, and the first process of recycling is to remove the paint. Paint removers include organic paint removers and alkaline paint removers. Organic paint removers are highly toxic and harmful to humans and the environment. Sodium hydroxide and corrosion inhibitors can be used to dissolve them by heating.

Working Principle

After the PCB is dismantled, it will be crushed. The crushing methods include impact crushing, extrusion crushing and shear crushing. The more commonly used technology is ultra-low temperature freezing and crushing technology, which can cool down tough materials, make them brittle and crush them, and completely dissociate metals and non-metals.

The pulverized material needs to be sorted according to the density, particle size, magnetic permeability, electrical conductivity and other characteristics of each component. Usually, there are dry and wet sorting. Dry separation includes dry screening, magnetic separation, electrostatic, density and eddy current separation, etc. Wet separation includes hydrocyclone classification,flotation, hydraulic shaker, etc. The separated substances can be reused.

FINAL PRODUCT

Products Description

PV Solar Panel Recycling Plant recycling process:

1.The aluminum frame removal machineThe PV panel wilbe fed into the frame removal machine via the hydraulic sucking disc to the hydraulic pushing system to move the frame.

2.The toughened glass removing machine The photovoltaic panel passed through the inside ofthe equipment,there are two roleriner side of the equipment to press the raw materal the glass is britle, sothat the alass willfall down.To avoid the ar polltion and fineness qlass powder fies into the air, lmpulse dust catching system is assembled with the whole system

3.EVA and Eva backplane Crushing and separating plant. Raw material of Eva willbe fed into the double shaft shredder outcome size 50*50mm. Then goes to the second hammer mi,outcomes size 10*20mm. Then theraw material willbe fed into the arinding svstem outcomes is under 3mm mixed metal. the aravity separator willsort the metal from non metals,then theelectrostatic separator macine senarate the slicon trom the plastic The whole svstem is assemped with the imouse dust catching svstem to avoid air polution

PRODUCT SPECIFICATIONS

|

Type

|

Aite-300

|

Aite-500

|

Aite-1000

|

|

Power kw

|

105

|

135

|

200

|

|

Weight KGS

|

15000

|

20000

|

30000

|

|

Dimension m

|

20*5*5

|

25*6*5

|

30*6*5

|

Hot Searches