When the acetylene content in the air reaches 2.5%~8%, the explosion will occur easily.Safety protection must been done

strictly for the C2H2 gas compressor.

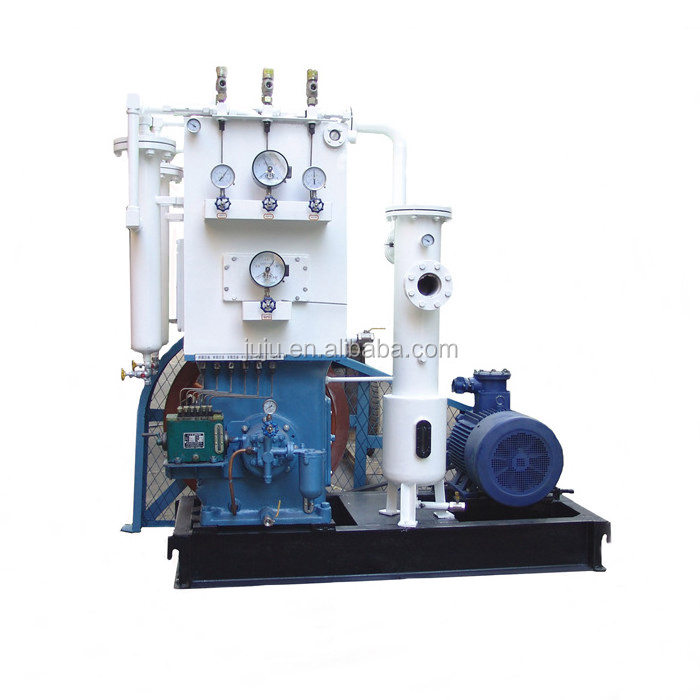

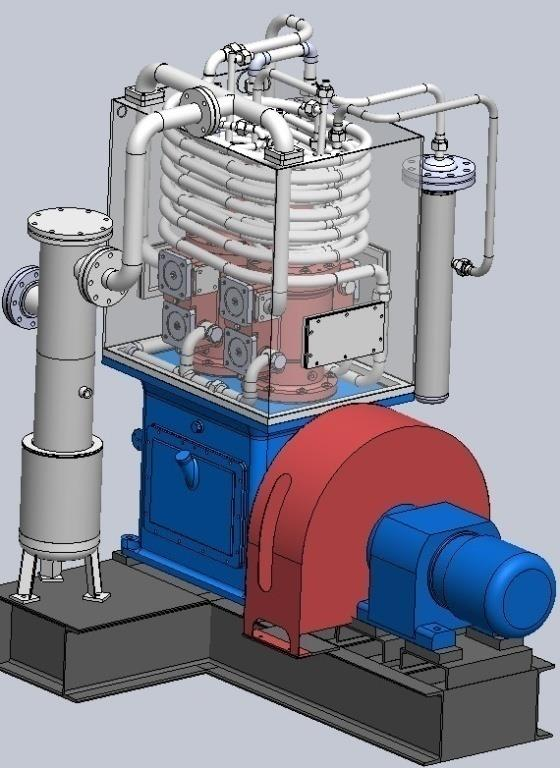

➢ For the Reciprocating piston acetylene compressors ,usually the cylinder and cooler are immersed in water, and sometimes

the body compressor is also in water. In this way, the water can fully absorb the heat generated in the process of compressed

gas and flow friction, avoid the explosion caused by high temperature, even if the combustion explosion occurs, the Fires can

be put out quickly; At the same time to observe the compressor external leakage is also more intuitive and convenient base

on this design.

➢The cylinder and the cooler are in the open water tank with large volume, the heat exchange cooling effect is better. At the

same time, because the cylinder and cooler under the water tank level, it will be easy to find and deal with the rising bubbles

when leakage occur timely.

➢Equipped with high quality intake separation filter.Acetylene gas source contains water and dust, will make lubricating oil

emulsification metamorphism, destroy its lubrication performance. When this water enters the fuselage oil pool, the entire oil

pool is destroyed.

The accumulation of water in the cylinder is easy to produce liquid percussion, resulting in a major accident. Good separation

and filtration of inlet acetylene gas will be of a great help of the safe and reliable operation of the compressor.

➢High flow acetylene compressors use double or multiple exhaust pipes to reduce pipeline velocity.

Automatic protection

*Compressor alarm and shut-up for low inlet pressure.

* Compressor alarm and shut-up for 3rd stage high discharge pressure .

* Compressor alarm for lubricating oil≤0.15MPa;

* Compressor shut-up for lubricating oil≤0.1MPa.

* Compressor alarm for 3rd stage discharge temperature ≥90℃ ;

* Compressor shut-up for 3rd stage discharge temperature ≥95℃

*Compressor alarm for water temperature ≥50℃ in the water box.