- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 410V

-

Dimension(L*W*H):

-

various

-

Weight:

-

5000 kg

-

Product name:

-

Downspout pipe roll forming machine

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

PLC(detla) System

-

Roller material:

-

High Grade 45# Forged Steel

-

Cutting blade material:

-

Cr12Mov Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Profiles:

-

Custom-made

-

Frame:

-

350H Beam Steel

-

Need container:

-

40GP

-

Machine Color:

-

Cusotmized

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

pipe machine

-

Production Capacity:

-

13--15M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 410V

-

Dimension(L*W*H):

-

various

-

Weight:

-

5000 kg

-

Product name:

-

Downspout pipe roll forming machine

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

PLC(detla) System

-

Roller material:

-

High Grade 45# Forged Steel

-

Cutting blade material:

-

Cr12Mov Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Profiles:

-

Custom-made

-

Frame:

-

350H Beam Steel

-

Need container:

-

40GP

-

Machine Color:

-

Cusotmized

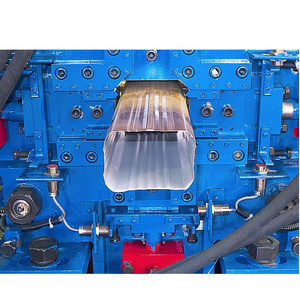

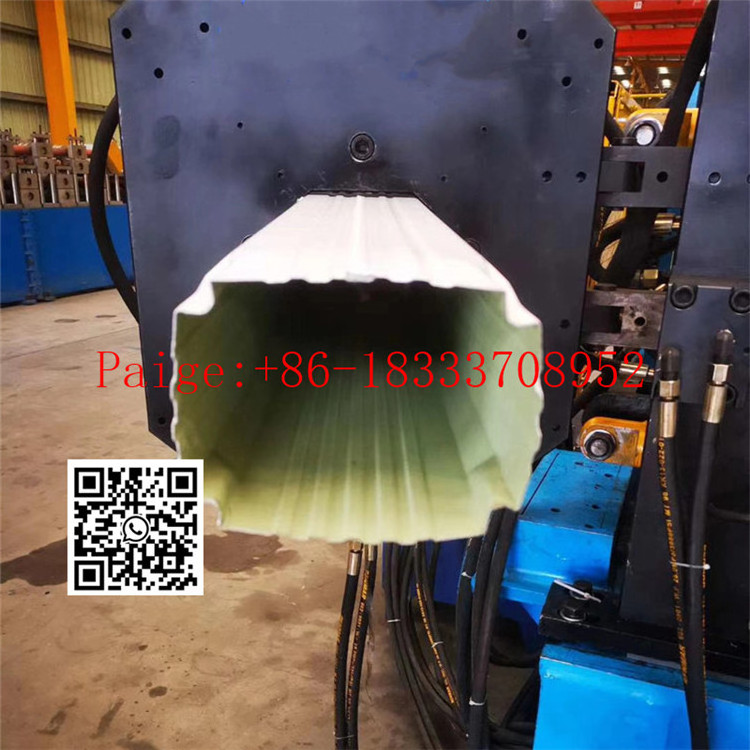

JCX 3' 4' pipe descent aluminium steel gutter square pipe roll forming machine

Product Overview

PRODUCT SPECIFICATIONS

|

Product Name

|

JCX JCX round or rectangle rain water steel downpipe spout gutter roll forming machine

|

|

Suitable material

|

Cold rolled coil,hot rolled coil, galvanized coil

|

|

|

Q235Mpa.Q350Mpa,Q550Mpa

|

|

|

0.3-0.8mm (Customized) 0.2-1.0mm or more

|

|

Coil

|

Feeding Width: (customized)

|

|

Forming speed

|

13-15m/min

|

|

Roller stations

|

15-24stations

|

|

Material of roller

|

45# steel finish maching , plated hard

|

|

Hardness of roller

|

HRC: 58-62

|

|

Material of main shaft

|

45# steel finish maching , then slack

|

|

Driven motor power

|

11Kw

|

|

Hydraulic station power

|

3 Kw

|

|

Hydraulic station pressure

|

12.0 Mpa

|

|

Electrical control system

|

Panasonic PLC

|

|

Material of cutter

|

Cr12 MOV

|

|

Hardness of cutter

|

HRC: 58-62

|

|

Driving mode

|

Single chain 1 inch

|

|

Power supply

|

380V, 60Hz, 3 Phase or as per request

|

|

Cutting accuracy

|

±1.5mm

|

|

Dimension(L*W*H)

|

6500mm* 600mm*1200mm

|

Customer Photos

Packing & Delivery

Sea worthy standard package: covered with plastic film, fixed into 1*20'gp container

Our Services

FAQ

Recommend Products

Standing seam roof panel machine

Double layer roof sheet roll forming machine

Hot Searches