FLexible

: Does not break or crack easily. Wastage is therefore reduced. Flexibility is enhanced when wet.

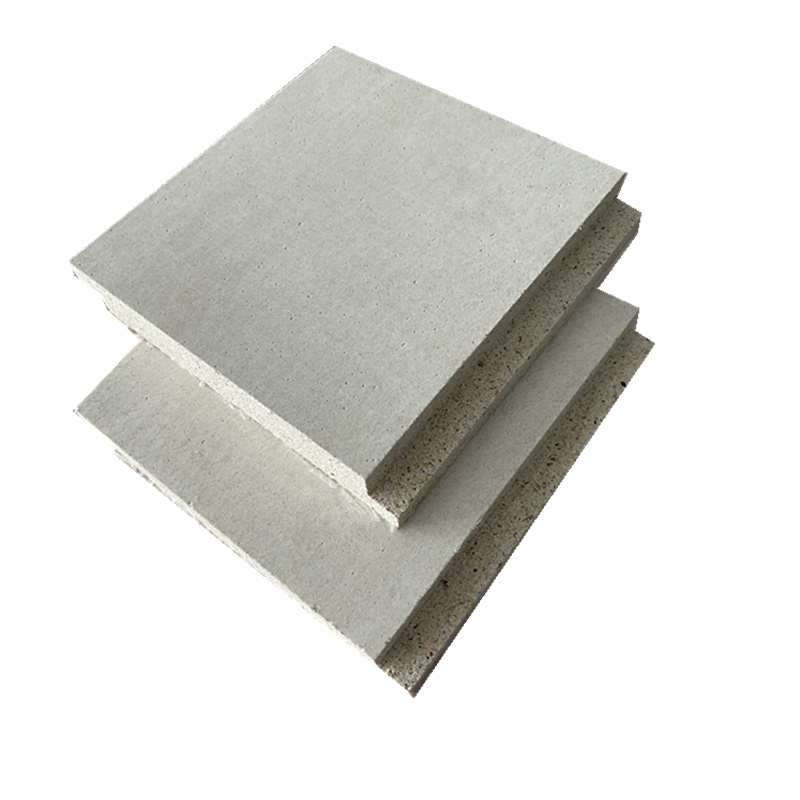

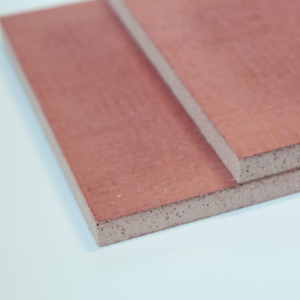

Strength

:Thicker MGO boards 16-20 mm are much stronger,and it has 4 layers fiberglass cloth.

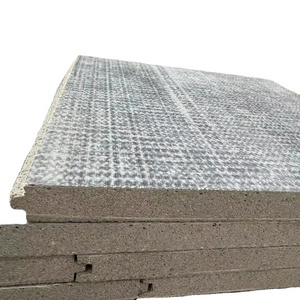

Quick Installation & Cutting:

MGO subflooring when making installation could be a super fastener to withdraw power to hold nails and screws like plywood. The dimension is stable, the panels will not buckle or warp like wood sheathing. It installs just like wood sheathing, a circular saw for cutting, and screws for fastening.