- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

215-137-3

-

Place of Origin:

-

Hebei, China

-

Application:

-

Granite

-

Brand Name:

-

prodrill

-

Model Number:

-

expansive mortar

-

Usage:

-

Blocks Cutting

-

Packing:

-

Carton Box

-

Purpose:

-

Alternative

-

Name:

-

Non Dexpan Explosive Demolition Agent

-

Payment:

-

L/C

-

Characteristics:

-

Soundless

-

Color:

-

Gray

-

Keyword:

-

Stone Breaking Chemical

-

Type:

-

Local Temperature

-

Brand:

-

Crackmax

Quick Details

-

CAS No.:

-

1305-62-0

-

Other Names:

-

Soundless Cracking Agent

-

MF:

-

Ca(OH)2

-

EINECS No.:

-

215-137-3

-

Place of Origin:

-

Hebei, China

-

Application:

-

Granite

-

Brand Name:

-

prodrill

-

Model Number:

-

expansive mortar

-

Usage:

-

Blocks Cutting

-

Packing:

-

Carton Box

-

Purpose:

-

Alternative

-

Name:

-

Non Dexpan Explosive Demolition Agent

-

Payment:

-

L/C

-

Characteristics:

-

Soundless

-

Color:

-

Gray

-

Keyword:

-

Stone Breaking Chemical

-

Type:

-

Local Temperature

-

Brand:

-

Crackmax

Prodrill High Range Soundless Cracking Agent ( HSCA ) are Non-explosive demolition Agents for Rock breaking, concrete demolition in quarrying, mining and construction.

Chemical name: Calcium Hydroxide, is a new commercial product which is an alternative to explosives and gas pressure blasting products used in demolition, mining, and quarrying.

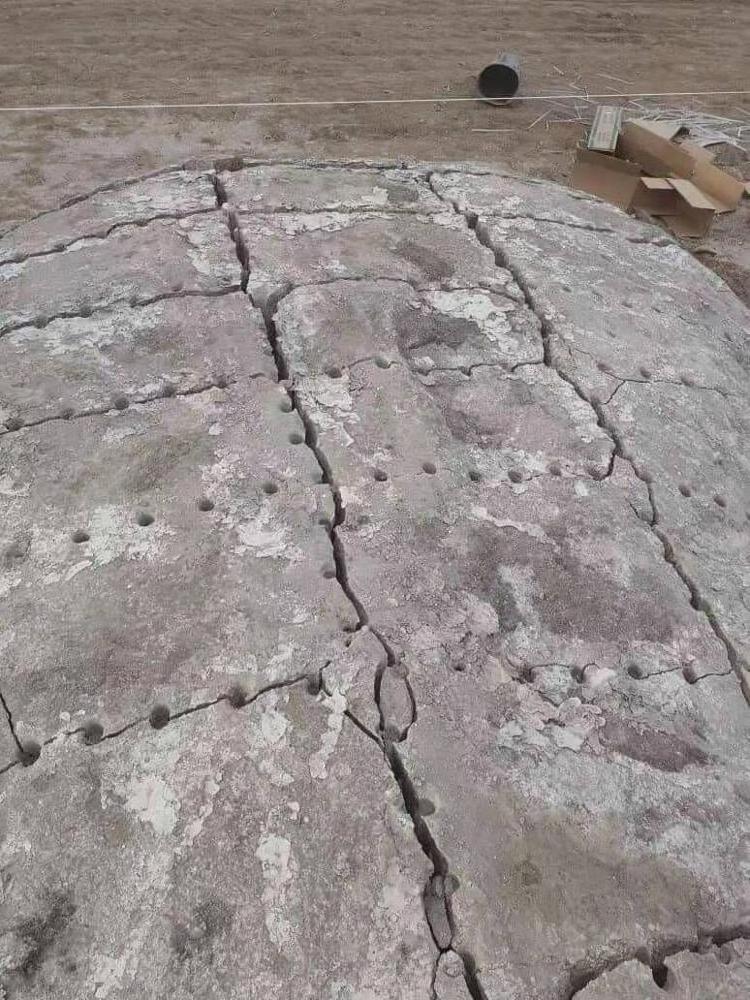

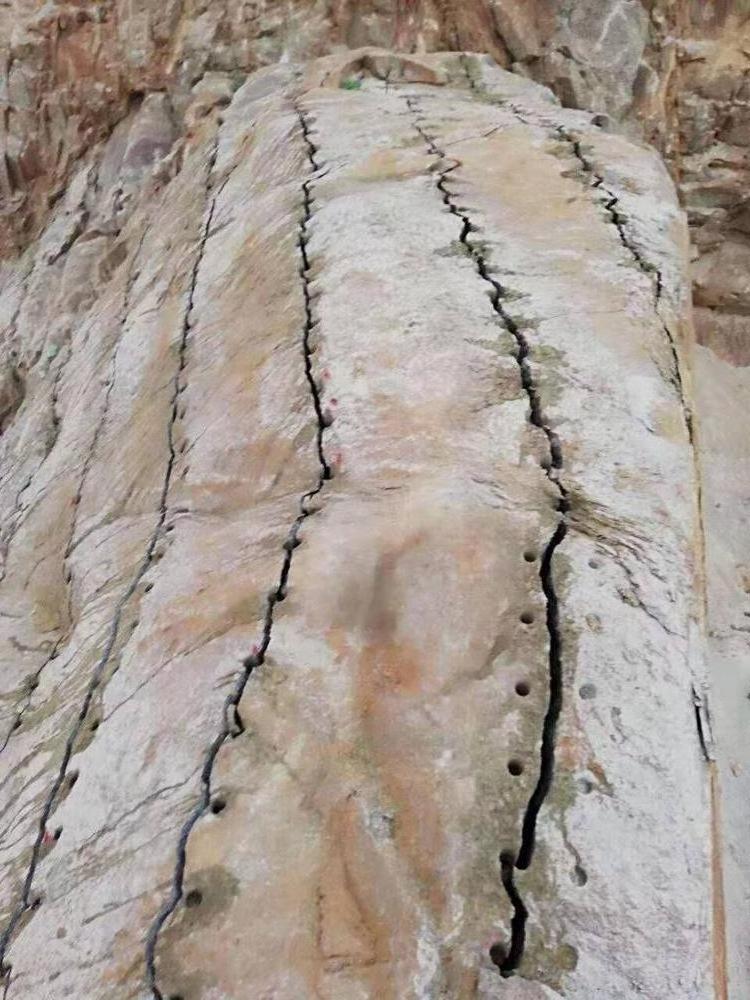

The use of the non-explosive demolition agents in rock demolition or quarrying is very easy, holes are simply drilled in the base rock like they would be drilled with the conventional explosives. Then a slurry mixture of the non-explosive demolition agent and water poured into it. Over the next few hours the slurry expands, cracks the rock in a pattern just like as it would occur with a conventional explosives.

Prodrill High Range Soundless Cracking Agent (HSCA) offers many advantages including the fact that it’s silent and do not produce vibration the way a conventional explosive would. In some applications conventional explosives are more economical than non-explosive demolition agents. In many countries these are available without restriction unlike explosives which are highly regulated.

HSCA advantages:

1. The fastest cut speed, and the most powerful expansive pressure, SCA-I,35ºC,30 Mpa at 8 hrs, 55 Mpa at 24 hrs. SCA-II,25ºC,20 Mpa at 8 hrs,45Mpa at 24 hrs.

An average of 5-6 hours to safely demolish rocks

2. Suitable even for non free surface and very tough rocks fracture, like the case of the Saudi Makkah area.

3. Safe, without blown-out shot during usage.

4. Strongest packing that assures a safe transportation.

5. The CaO percentage is 95% higher than in the expansive mortar.

6. Oversize horizontal rotary kiln.

7. HSCA is in grey or balck.

8. Max hole diameter for HSCA is 45-65mm, normally diameter is from 30-40mm.

9. Burning temperature of HSCA is over 1450 Degree Celsius.

10. The HSCA C4 is specially designed for the extremely high temperature zones like the case of Saudi

Arabia.

Technical Specification

There are three types of Expansive mortar for traditional type, depending on usable temperature, details as below:

|

Type no. |

Usable Local Quarry Temperature |

|

CI or C1 |

25°C ~ 40°C (or 77°F ~ 104°F) |

|

CII or C2 |

10°C ~ 25°C (or 50°F ~ 77°F) |

|

CIII or C3 |

-5°C ~ 10°C (or 23°F ~ 50°F) |