- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TLS-02

-

material:

-

fiber reinforce plastic/fiber glass mold

-

Usage:

-

make FRP pools

-

design:

-

As the customer' requirement

-

Mould Life:

-

5 Years

Quick Details

-

Shaping Mode:

-

vacuum

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tengli Spamold

-

Model Number:

-

TLS-02

-

material:

-

fiber reinforce plastic/fiber glass mold

-

Usage:

-

make FRP pools

-

design:

-

As the customer' requirement

-

Mould Life:

-

5 Years

Fiberglass swimming pool mold

Specifications

|

Product: |

Fiberglass swimming pool mold |

|

Min. Order: |

1 Set |

|

Transportation: |

by Sea |

|

Product Material: |

Fiberglass reinforce plastic |

|

Shaping Mode: |

spray |

|

Export Markets: |

North America, South America, Eastern Europe, Southeast Asia, Western Europe, Mid East |

|

Payment: |

T/T |

|

Making production |

FRP swimming pool |

|

Size |

customized |

About Us

Foshan Tengli Spamold & Equipment Factory is the one professional factory that designs and manufactures the molds of spa ,swimspa . We customize all kinds of vacuum forming molds, FRP pool molds for our customers such as swimming pool mold,outdoor spa mold, jacuzzi mold, bathtub mold, steam room mold, shower tray mold, artificial stone mold and the mold is make of FRP(fiber reinforce plastic) etc.

This is our picture on Canton Fair :

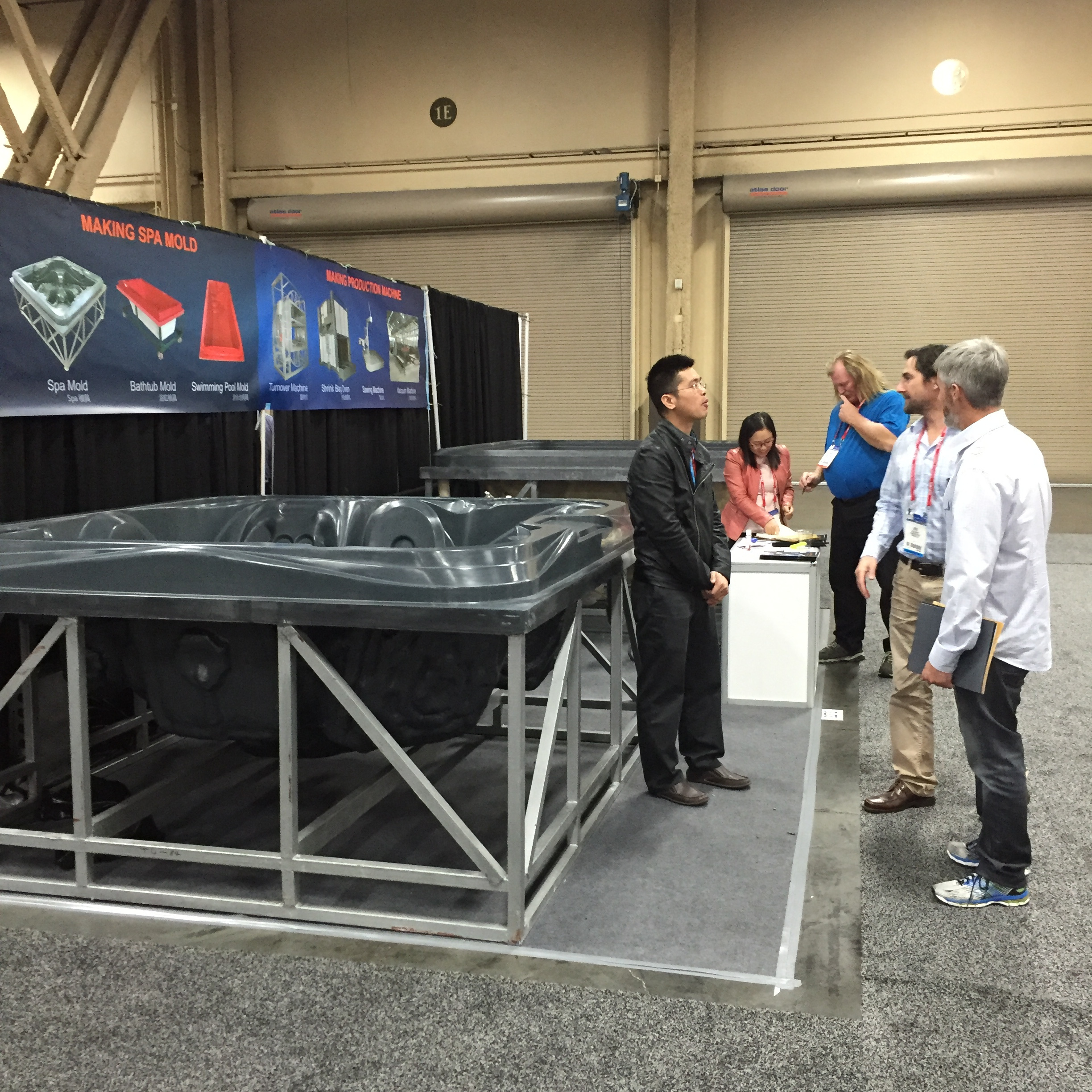

This is our pictures in U.S. pool show:

With the 24+ year experience in mold manufacturing makes us become the outstanding factory in FRP mold industry. Our factory have a professional mold design team and the high-level of molders.we are proficient in all production processes of vacuum forming productions and FRP product.Every detail of mold required to achieve excellence.The molds we design have reasonable layout,novel style and high-quality.We can ensure that all the molds canbe vacuum-formed successfully at the first time,unless repair:

Details:

Our mold can make swimming pool spa mold like the pictures below:

FRP

The main material of our mold is high-strength FRP(Fiberglass reinforce plastic). High compression strength and excellent convertibility make us easier to create any complicated and irregular moulds and shorten the production time.

Our advantage

1 , Comprehensive design level :18-year experience in mold and productions manufacturing make product design more reasonable,more beautiful,more comfortable Our advantage:

→ market more guarantee:the shortest delivery time for spa mold is 30days.

2 , Exquisite in workmanship :professional technology,strict quality control,stop mold appear defect like rough,bubble,deformation,flaw completely.

3 , Concise program : to lower technician press mostly,all the design we try our best to do it for you.

4 Guarantee maintain :2years free maintain for local area client,maintain technology canbe offer free toother area

The process of making a mold ( the picture is only an example )

1,Make the drawing asper the requirement of customers or the draft or pictures from them.

2,Send the drawing to the customer by email and ask them to confirm the position of air valve,water valve and skimmer etc.as well as the layout of the jets.If there is any modification,the amended drawing will be resent until final confirmation.

3,Make the plaster mold as per the final drawing and then send the pictures to customers for confirmation by email.Any modification,the plaster mold will be change until final confirmation.

4,After finish the plaster mold,the next is to make stage mold.The surface of the stage mold will be trimed and polished to get a perfect surface.

5,Make the production mold,repolish and retrimed carefully until it meets the highest requirement of suction mold.

our factory: