- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

according to the machine

-

Year:

-

latest

-

Power (kW):

-

65 kW

-

Weight (KG):

-

9000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

function:

-

make waste tires and rubber into rubber crumb and rubber powder

-

Transportation:

-

one 40GP container

-

Max roller spacing:

-

10 mm

-

raw material:

-

waste tires

-

Roll ratio:

-

1:2.5

-

Diameter of roll:

-

400-560mm

-

Motor revolution speed:

-

760-980 r/min

-

Front roll liner speed:

-

34.5-44 m/min

-

After Warranty Service:

-

Online Support

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Huarui

-

Core Components:

-

main host

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

according to the machine

-

Year:

-

latest

-

Power (kW):

-

65 kW

-

Weight (KG):

-

9000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

function:

-

make waste tires and rubber into rubber crumb and rubber powder

-

Transportation:

-

one 40GP container

-

Max roller spacing:

-

10 mm

-

raw material:

-

waste tires

-

Roll ratio:

-

1:2.5

-

Diameter of roll:

-

400-560mm

-

Motor revolution speed:

-

760-980 r/min

-

Front roll liner speed:

-

34.5-44 m/min

-

After Warranty Service:

-

Online Support

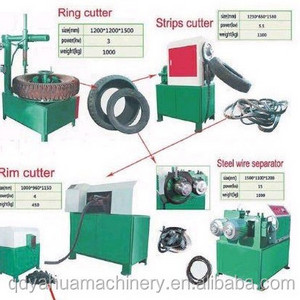

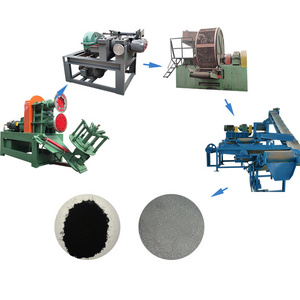

Waste tyre recycling line to produce reclaimed rubber powder tire recycling machine

Function: Our whole recycling machine line is used to make waste tires into rubber

powder.

Major flow: Waste tires-circle cutting-strip cutting-block cutting- grind into powder- magnetic separation-fiber separation -packing-put in storage .

Our tire recycling line has following outstanding advantages:

No pollution : Separate the fiber, wire and rub b er completely under normal temperature by physicalmethods, zero-emission of waste gas, water and feigh.

Low consumption : L owest energy consumption and labor cost.

High capability : Capable of disposing the waste t i res which the diameter is less than 12 5 0 mm into 5-40 mesh crumb rubber.

Specification of Recycling machine old tire line

1. QQJ-40 Tire Circle Cutter

Application: used for separating the sidewall of the waste tire from its tire

cro

w

n.

3. QTJ-390 Tire Strip Cutter

Application:It’s used for cutting the tire tread and sidewall into strips 5*8cm.

4. QKJ-358 Tire Slice Cutter

Application:It’s used for cutting the strips into small slice about 3*5*8cm.

5. XKP Tire Crusher (W ith 5Cr6MnMo roller s )

Application:It’s used for grinding the slice into smaller mesh powder through the vibrating screen

as you need.

|

Model No. |

XKP - 350 |

XKP - 400 |

XKP - 450 |

XKP - 560 |

XKP - 560L |

|

Diameter of front roll |

300 mm (groove) |

400 mm (groove) |

450 mm (groove) |

560 mm (groove) |

560 mm (groove) |

|

Diameter of back roll |

300 mm (groove) |

400 mm (groove) |

450 mm (groove) |

510 mm (groove) |

560 mm (groove) |

|

Drum working length |

500mm |

600mm |

760mm |

800mm |

1000mm |

|

Front roll liner speed |

26.2m/min |

34.5 m/min |

38.0 m/min |

40.6m/min |

44m/min |

|

Roll ratio |

1:2.5 |

1:2.5 |

1:2.5 |

1:2.5 |

1:2.5 |

|

Max roller spacing |

10mm |

10 mm |

10 mm |

10 mm |

10mm |

|

Motor power |

30KW/37KW |

45KW/55KW |

75KW / 90 KW |

90 KW/ 110 KW |

132 KW/1 60 KW |

|

Weight |

6T |

8.5 T |

11T |

17.5T |

21T |

|

L*W*H |

3.5*1.6*1.5m |

4.3*1.8*1.6m |

4.6*2.0*1.65m |

5.3 * 2.0*1.7m |

5.6*2.0*1.7m |

6. Magnetic separator (2sets:The first magnetic separator is rough separator and the second one is fine separator.)

Application:It’s used for separating the steel wire from the rubber powder.

7. TFS1000 Fiber separator

Application:It’s used to separate fiber, nylon and small wire from both nylon waste tire and steel

wire tires.

Our tire recycling machines have been exported to many countries such as Algeria, Brazil, New Zealand, Jordan, America, Oman, Nicaragua, Tunisia, England, India, Mexico, Argentine, Turkey, Canada, Thailand, South Korea, Czech Republic, Russia, Belarus, Lebanon, Georgia and so on.

Why choose us?

1.Guarantee : 2 years after commissioning.

2.Installation : Engineers available to service machinery overseas.

3.Wherever you are, we have experience, knowledge, and skills to meet your needs and satisfy

your requirements

4.More than 3 0 years of experience.

5.They are our patented products and they are 1/3 energy saving!

CE Certificate

Customers visiting our factory and cooperating with us