- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*2600*950mm

-

Application:

-

wood furniture, wood cutting

-

Weight (KG):

-

650 KG

-

Power (kW):

-

5.6

-

Max.Cutting Height at 90°(mm):

-

75mm

-

Max.Cutting Height at 45°(mm):

-

75mm

-

Max. Length of Workpiece (mm):

-

2800mm

-

Applicable Industries:

-

wood furniture, wood cutting

-

Sliding table size:

-

2800*375mm

-

Max cutting length:

-

2650mm

-

Max cutting width:

-

1250mm

-

Cutting saw diameter:

-

300mm

-

Max cutting thickness:

-

75mm

-

Main shaft speed:

-

4500/6000

-

Main shaft diameter:

-

30mm

-

Max. Working Speed:

-

25000mm/min

-

Tilting saw blade:

-

0-45 degree

-

Main Motor power:

-

4kw

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

WISE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2800*2600*950mm

-

Application:

-

wood furniture, wood cutting

-

Weight (KG):

-

650 KG

-

Power (kW):

-

5.6

-

Max.Cutting Height at 90°(mm):

-

75mm

-

Max.Cutting Height at 45°(mm):

-

75mm

-

Max. Length of Workpiece (mm):

-

2800mm

-

Applicable Industries:

-

wood furniture, wood cutting

-

Sliding table size:

-

2800*375mm

-

Max cutting length:

-

2650mm

-

Max cutting width:

-

1250mm

-

Cutting saw diameter:

-

300mm

-

Max cutting thickness:

-

75mm

-

Main shaft speed:

-

4500/6000

-

Main shaft diameter:

-

30mm

-

Max. Working Speed:

-

25000mm/min

-

Tilting saw blade:

-

0-45 degree

-

Main Motor power:

-

4kw

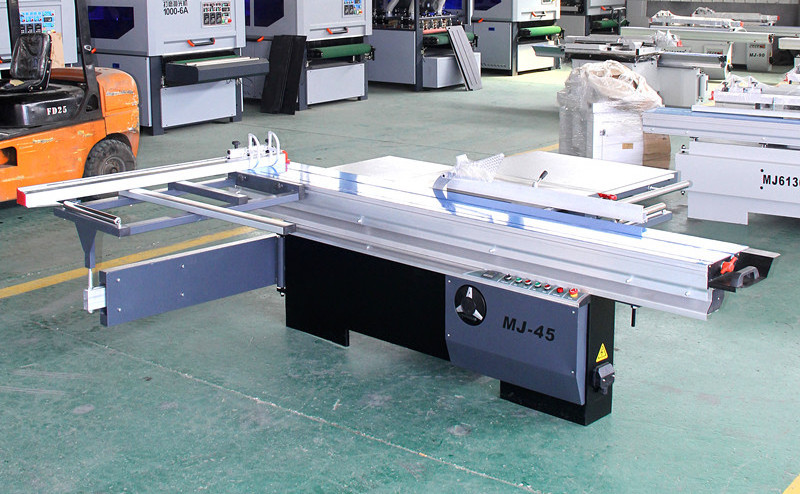

Product Overview

Wood sliding table panel saw Attachment Cutting Machine Precision industrial wood saws MJ6132YIB In China With CE

Precision panel saws (or: sliding table saws) can be used for longitudinal and transverse cutting of various wood-based panels such as veneer particleboard, fiberboard, plywood and solid wood panels, plastic panels, aluminum alloys, etc., and are widely used in panel furniture Wood processing industries such as industry and vehicle and ship manufacturing are general-purpose equipment among woodworking machinery, and the market demand is relatively huge.

FEATURES AT A GLANCE

Outlook 1

Outlook 2

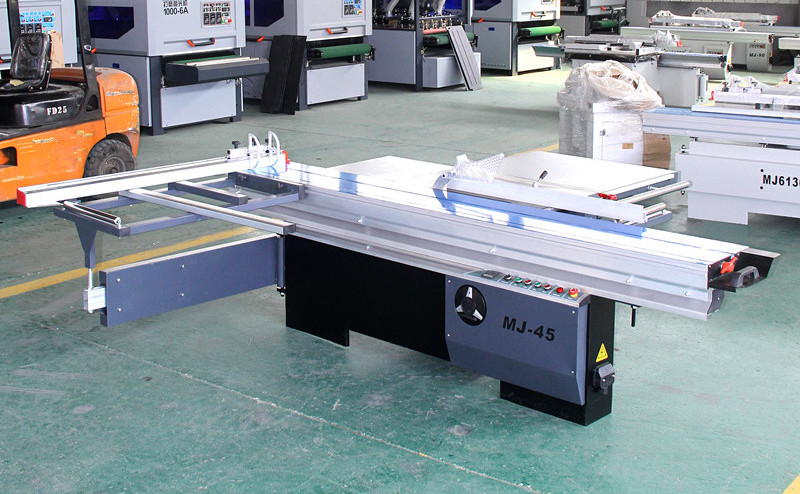

Outlook 3

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

||

|

1

|

Model

|

MJ45-2800 SLIDING TABLE SAW

|

|

|

||

|

2

|

Sliding table size

|

2800*375mm

|

|

|

||

|

3

|

Max cutting length

|

2650mm

|

|

|

||

|

4

|

Max cutting width

|

1250mm

|

|

|

||

|

5

|

Cutting saw diameter

|

300mm

|

|

|

||

|

6

|

Max cutting thickness

|

75mm

|

|

|

||

|

7

|

Main shaft speed

|

4500/6000

|

|

|

||

|

8

|

Working pressure

|

6kg

|

|

|

||

|

9

|

Main shaft diameter

|

30MM

|

|

|

||

|

10

|

Max. Working Speed

|

25000mm/min

|

|

|

||

|

11

|

Tilting saw blade

|

0-45 degree

|

|

|

||

|

12

|

Main Motor power

|

4kw

|

|

|

||

|

13

|

Scoring saw blade dia

|

120mm

|

|

|

||

|

14

|

Scoring saw blade speed

|

8000rpm

|

|

|

||

|

15

|

Secondary shaft diameter

|

20mm

|

|

|

||

|

16

|

Secondary shaft motor power

|

0.75kw

|

|

|

||

|

17

|

Weight

|

650kg

|

|

|

||

|

18

|

Machine overall size

|

2800*2600*950mm

|

|

|

||

|

19

|

Package size

|

2800*1100*950mm

|

|

|

||

PRODUCT CONFIGURATION

European-style step-by-step lock, double-layer thickened round rod chrome-plated guide rail, high pressure bearing capacity, smooth driving when cutting heavy plates, more precise cutting, improving the life and accuracy of the whole machine

Use electric lifting, digital display function, upgrade the traditional manual mode, one-key lifting, simpler operation, digital display to adjust the angle, more precise, complementary, one step to finish whole operation of sliding table saw

Double saw blade structure, clear division of labor, small saw to scribe line, large saw to cut the board, to prevent board burrs, chipping and other phenomena

high precision, good performance, good cutting effect

High-power pure copper motor, upgraded main saw power 5.5kw, small saw 1.1kw, strong power and long service life of siding table panel saw wood cutting machine

European style ruler, stable and non-shifting, ensuring that the plate does not shift during the cutting process. Equipped with a magnifying glass, cutting is convenient and more precise

The non-deformable cast iron table top, 760*980cm enlarged and widened auxiliary worktable, will not slide after being fixed, and the cutting is convenient and accurate

SIMILAR PRODUCTS

Automatic edge banding machine

for panel furniture edge sealing

manual sliding table saw

for wood mdf cutting

nesting cnc router

for cabinet door panel furniture cutting

SALES AND SERVICE NETWORK

FAQ

Q 1. How many days can I expect the machine?

A 1: For fiber laser marking machine, if with standard device, its ready to ship.

Other kind of cnc wood machine and laser

machines delivery time is about 20-30 days according to quantity and special device request

Q 2: How many years warranty can I get?

A 2: We provide 3 years warranty for Fiber Laser Machine,Provide 1 year warranty for Other cnc and laser machine such as wood cnc router, stone cnc router, foam cutting machine, flatbed cutter etc.

Q 3: How about Training and after sale service?

A 3: WE have operation and installation video for woodworking machine, metal fiber laser marking machine, foam machine, stone machine,co2 laser cutting machine etc. WE provide 24 online support for software operation, problem setting etc.

Q 4: Whats will be transportation way for the machines?

A 4: for small machines such as fiber laser marking machine, handheld laser welding machine, 3030 desktop cnc router, we can ship it through air, only take 5-7 days to arrive customer's place. For big machines such as fiber laser cutting machine, flatbed cutting machine, hot wire foam cutter, atc cnc router, we will use sea transportation.

Q 5: What will be the package for cnc and laser machine?

A 5: For LCL shipment based on buy 1 set or 2 set, we will use fumigation-free plywood case. For mass purchase such as 6-20 sets panel saw, 6-9 sets 1325 cnc router,we will use film pearl cotton package, and ship by 40'HQ container.

Other kind of cnc wood machine and laser

machines delivery time is about 20-30 days according to quantity and special device request

Q 2: How many years warranty can I get?

A 2: We provide 3 years warranty for Fiber Laser Machine,Provide 1 year warranty for Other cnc and laser machine such as wood cnc router, stone cnc router, foam cutting machine, flatbed cutter etc.

Q 3: How about Training and after sale service?

A 3: WE have operation and installation video for woodworking machine, metal fiber laser marking machine, foam machine, stone machine,co2 laser cutting machine etc. WE provide 24 online support for software operation, problem setting etc.

Q 4: Whats will be transportation way for the machines?

A 4: for small machines such as fiber laser marking machine, handheld laser welding machine, 3030 desktop cnc router, we can ship it through air, only take 5-7 days to arrive customer's place. For big machines such as fiber laser cutting machine, flatbed cutting machine, hot wire foam cutter, atc cnc router, we will use sea transportation.

Q 5: What will be the package for cnc and laser machine?

A 5: For LCL shipment based on buy 1 set or 2 set, we will use fumigation-free plywood case. For mass purchase such as 6-20 sets panel saw, 6-9 sets 1325 cnc router,we will use film pearl cotton package, and ship by 40'HQ container.

Product packaging

package for wood cnc router, plasma cutting machine and laser machine.

For LCL shipment, such as buying one set cnc router or laser machine, we will use seaworthy fumigation-free plywood case

For FCL shipment, such as buying 6-9 sets wood cnc router or plasma cutting machine, we will use soft package, we use film and

pearl cotton to pack the machine, sometimes will unassemble machine gantry, motor etc in order to load more sets into one

container to help customer save shipping cost of each woodworking machine.

For FCL shipment, such as buying 6-9 sets wood cnc router or plasma cutting machine, we will use soft package, we use film and

pearl cotton to pack the machine, sometimes will unassemble machine gantry, motor etc in order to load more sets into one

container to help customer save shipping cost of each woodworking machine.

Hot Searches