- Product Details

- {{item.text}}

Quick Details

-

Products::

-

automobiles, home appliances, medicine, daily necessities, etc

-

Mould cavity material::

-

P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc

-

Mould base material:

-

Steel 1045

-

Runner Type:

-

hot or cold runner

-

Service Life:

-

500-1000 thousand times

Quick Details

-

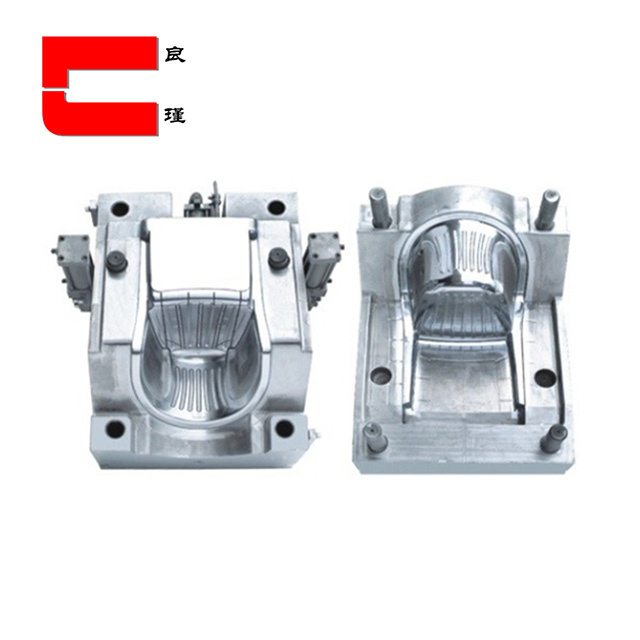

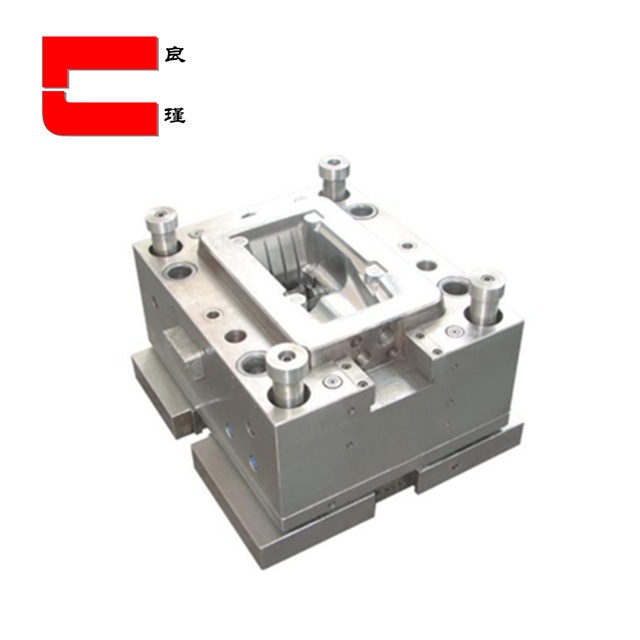

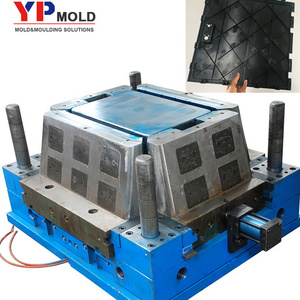

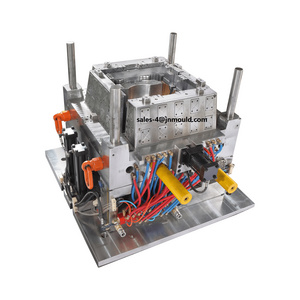

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Product material::

-

ABS,PP,PC ,PA6,PA66,etc

-

Products::

-

automobiles, home appliances, medicine, daily necessities, etc

-

Mould cavity material::

-

P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc

-

Mould base material:

-

Steel 1045

-

Runner Type:

-

hot or cold runner

-

Service Life:

-

500-1000 thousand times

Ningbo L&J Mould Co.,Ltd. is located in China-Ningbo which is one of the most famous port city. It’s an hour by car to Ningbo Port, 30 minutes to airport, railway station or bus station from our company.

After more than 10years of continuous development, we have become a specialized manufacturer and seller of moulds, plastic injection parts, rubber parts, die casting parts, stamping parts, CNC machining parts, and other hardware. Based on the first-class equipments, advanced management and innovative technology, we have successfully designed and manufactured a number of high-level high-tech molds and products. Our products involve automobiles, home appliances, medicine, daily necessities, sanitary wares, photographic equipment accessories, and construction fields, etc.

These years, our products have enjoyed a high reputation in Americas, Europe, Middle East and many other countries because we always offer customers high quality products, competitive prices and best service. We will, as always, abide by the heavy contracts and keep promises. Welcome for inquires.