Our unmatched expertise and technical knowledge of PET packaging helps you achieve more.

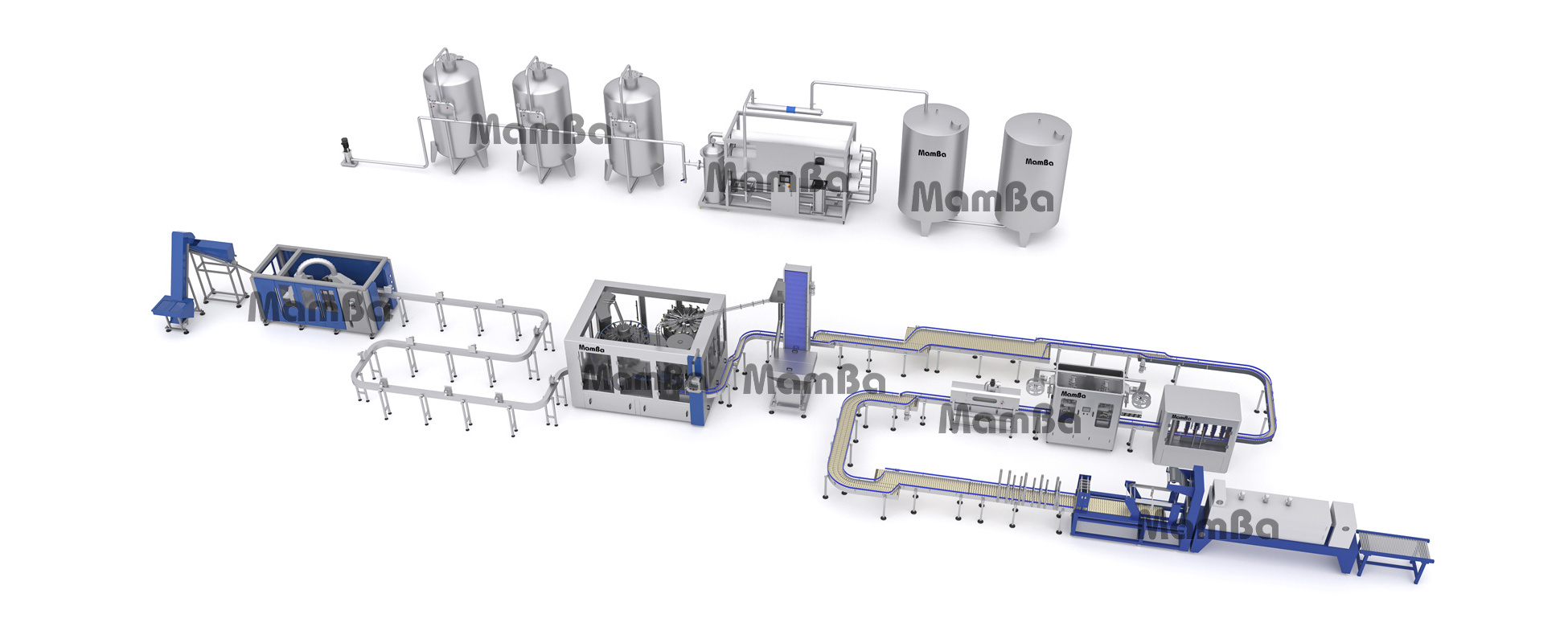

With over 30 years of experience in designing and implementing customised complete PET line

solutions for carbonated soft drinks,we can help you expand your line's production capabilities.

Over the years, we have significantly reduced the weight of CSD

bottles while retaining bottle resistance and expanding design opportunities.