- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.2%

-

Voltage:

-

220-600V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIEHE

-

Weight:

-

500 KG

-

Product name:

-

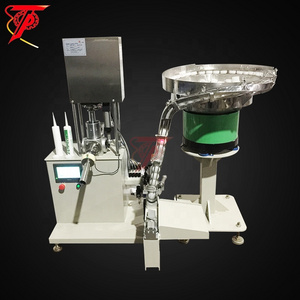

Cartridges Filling machine (Full auto machine)

-

Suitable for:

-

High viscosity materials

-

Filling capacity:

-

20-60 pcs/min

-

Filling size:

-

310ml(adjustable)

-

Air source needed:

-

0.6-0.8Mpa

-

Material:

-

SS304/SS316L

-

Multi filling heads:

-

Optional

Quick Details

-

Machinery Capacity:

-

Other, 500BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Metal, Other

-

Filling Material:

-

Adhesives, Silicone Sealant

-

Filling Accuracy:

-

±0.2%

-

Voltage:

-

220-600V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIEHE

-

Weight:

-

500 KG

-

Product name:

-

Cartridges Filling machine (Full auto machine)

-

Suitable for:

-

High viscosity materials

-

Filling capacity:

-

20-60 pcs/min

-

Filling size:

-

310ml(adjustable)

-

Air source needed:

-

0.6-0.8Mpa

-

Material:

-

SS304/SS316L

-

Multi filling heads:

-

Optional

Products Description

※ Application Industry:

This units of filling machines, are used in the high viscosity of materials filling and package. Widely used in the Silicone sealant, MS sealant, Two Components adhesive, and other types of adhesives. There are filling machines suitable for the Adhesive Sausage Films, Cartridges, and A/B components Cartridges etc.. Full auto and semi auto filling machines are all available.

※ Working process: The filling machines normally works with high viscosity mixers, such as butterfly type disperser, Two or three shaft multifunctional mixer, and double planetary mixer. And the extrusion machine. After materials mixed in the high viscosity mixer, use extrusion machine to press to discharge materials. Extrusion machine connected with packing machine, to achieve different filling.

※ Working process: The filling machines normally works with high viscosity mixers, such as butterfly type disperser, Two or three shaft multifunctional mixer, and double planetary mixer. And the extrusion machine. After materials mixed in the high viscosity mixer, use extrusion machine to press to discharge materials. Extrusion machine connected with packing machine, to achieve different filling.

Product Usage

ADHESIVE PRODUCTION LINE

with heating / cooling system,vacuum system as well as other related functions.

◈Extrusion machine, used to press materials out from the drum, to discharge materials:extrusion machine can lift up the drum little higher, to discharge materials.

◈Full auto filling machine. connects with the extrusion machine,to fill the materials into the cartridges.

Technical Paramenter

Cartridges Filling machine (semi auto machine)

1. Manually feed the cover to the cover box, turn on the total power,manually connect the bottle to the filling port.

2.Filling machine feed the bottle automatically, after filled.manually move the bottle to the cover press device.

3. Cover press system work together with the air source system (press cover and release air).after cover pressed, machine convey the finished product automatically out of filling qmachine, then manually feed into the box.

Filling capacity: 0-20pcs/min

3. Cover press system work together with the air source system (press cover and release air).after cover pressed, machine convey the finished product automatically out of filling qmachine, then manually feed into the box.

Filling capacity: 0-20pcs/min

Filling size:

100-400ml(adjustable)

Air source needed:

0.6-0.8Mpa

Cartridges Filling machine (Full auto machine)

1. Manually put the plastic bottle and the bottom cover into the box, turn on the main power switch of the touch screen, and press the RUN button.

2. The machine will automatically work in a chain, starting from left to right and automatically feeding the plastic bottles to the filling port, and bottom caps to the capping place.

3. When the plastic bottle reaches the filling port, the manipulator moves the plastic bottle forward to the filling mouth.

4. The filling mechanism starts to fill the plastic bottle with materials, and the manipulator slowly pull the rubber bottle back, the shredding mechanism starts to work after the filling is completed, and the shredding is quickly rotated.

5. After shredding, the operation mechanism continues to move the rubber bottle from left to right into the next capping mechanism. The capping mechanism and The exhaust mechanism works at the same time.

6. After capping is completed, the operating mechanism will move the plastic bottle from leftto right into the next coding mechanism.

7. After the coding, the operating mechanism wil move the plastic bottle from left to right and send the finished product out of the filling machine.

8. Manually feed the finished bottles into the box.

Filling capacity: 20-60 pcs/min

3. When the plastic bottle reaches the filling port, the manipulator moves the plastic bottle forward to the filling mouth.

4. The filling mechanism starts to fill the plastic bottle with materials, and the manipulator slowly pull the rubber bottle back, the shredding mechanism starts to work after the filling is completed, and the shredding is quickly rotated.

5. After shredding, the operation mechanism continues to move the rubber bottle from left to right into the next capping mechanism. The capping mechanism and The exhaust mechanism works at the same time.

6. After capping is completed, the operating mechanism will move the plastic bottle from leftto right into the next coding mechanism.

7. After the coding, the operating mechanism wil move the plastic bottle from left to right and send the finished product out of the filling machine.

8. Manually feed the finished bottles into the box.

Filling capacity: 20-60 pcs/min

Filling size:

310ml(adjustable)

Air source needed:

0.6-0.8Mpa

Recommend Products

Hot Searches