- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

105kw

-

Dimension(L*W*H):

-

3*2*2M

-

Weight (KG):

-

4500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

A vacuum:

-

Metal film layer of conductive membrane

Quick Details

-

Machine Type:

-

JYC-0708, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Curing oven, Coating Equipment, Anodized Equipment, Other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Junying

-

Voltage:

-

380V

-

Power:

-

105kw

-

Dimension(L*W*H):

-

3*2*2M

-

Weight (KG):

-

4500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

A vacuum:

-

Metal film layer of conductive membrane

Suitable for conductive film layer plated conductor and semiconductor products

INTRODUCTIO

Ningbo Junying Vacuum Machinery Co., LTD. is a High technology enterprise of integrity of research, manufacture, distribution and service. Since its foundation, we are mainly on high technology material production, vacuum device research and sales home and abroad.

Our vacuum device is designed by famous professor in china vacuum field, we also cooperate with

BEIJING GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS ,

and many other vacuum manufactories in recent years, we have made outstanding achievement on surface equipment, new technology processing, and usage of new material, providing whole set of equipments and materials for vacuum factory.

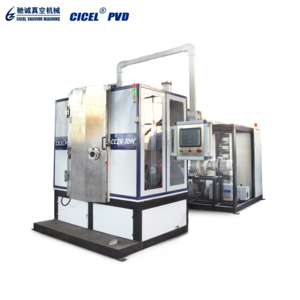

JYCL—7060

Magnetron sputtering continuous coating production line; There are 625mm 505mm material trays with 20 plates, one Max 35 digs and one feeding Max up to 700 digs. The automatic feeding tray structure is equipped with a Ky-400 high vacuum molecular pump or 10F Cryo pump, and Rotary pump + Booster low vacuum pump. The pumping rate can reach 10000 L/hr.

Production efficiency:

1-1 Equipment capacity (0603) : 142(bars)×70(grains)× 35(fixtures)× 20(plates) ×36(2HR /40min) ×30 days ×85%(moving rate) = 6 billion PCS/month 1-2 Production cycle: About 40 minutes

1-3 Regeneration time:

About 3 hours (1.5 hours for ventilation, 1.5 hours for regeneration)

BUSINESS SCOPE:

Whole set Vacuum coating equipment and technology, pum p, valve, vacuum gauge, oil, grease, sealing, vacuum coating material, metal and alloy. Debugging and improving vacuum equipment, surface processing and technology research on new type plastic, metal, glass, provide fittings and counseling.

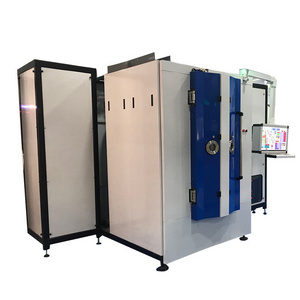

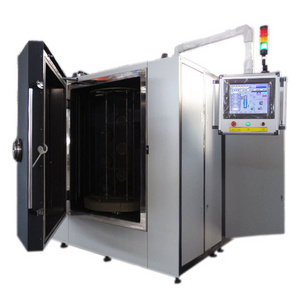

Single door steam resistance type vacuum coating machine This equipment by resistance heating vacuum chamber, melting and evaporation of wire, sheet, aluminum, copper, silver piece) insist on resistance wire. Evaporate molecules deposited on metal substrate, smooth film and high reflectivity. So the surface of the project can be decoration and beautification. Characteristic: reasonable structure, even film, film formation, high quality quick pumping speed, short cycle, high efficiency, convenient operation, low energy consumption, stable performance, etc. Application industry: widely used in electrode contact, automobile, acoustics, all kinds of household appliances, computers, watches and clocks, toys, mobile phones, reflective glass, cosmetics, toys, tableware, sanitary ware, heel, ABS, PS, PVC, PET, PP, PC, nylon, metal, boli, glass, ceramic, TPU etc. Plating: general plating surface, dumb - all (half dumb, dumb), electroplating process lines, wire drawing, raindrops, colorful; Coating color: gold, silver, red, blue, green, purple, color, and so on. We can design the size of the vacuum chamber according to your request. We can also design and configuration of the vacuum device and electric control system according to your requirements.

Professional manufacturer of passive component preparation!

Best regards; Looking forward to your reply!

Wechat: nbjunying