- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LJ

-

Model Number:

-

LJ01

Product Description

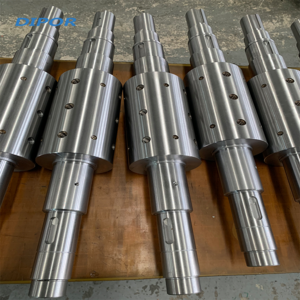

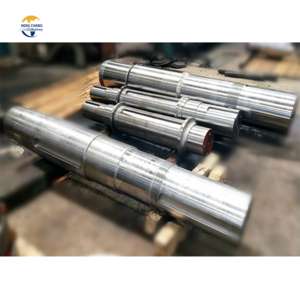

We can produce large forging,casting and welding gears according to customer's drawings.According to the working conditions and clients' request,we also can do gear grinding,surface hardening,cemented and quenching,Nitriding and quenching,etc.As known high fatigue strength, resistance to abrasion & corrosion and long service life, these shafts undergo various quality tests to ensure flawlessness of products.

Forged steel work roll performs as a tool to transform materials under normal room temperature, therefore , it is the most wear and tear spare parts during the rolling process . With 2%Cr, 3%Cr, 5%Cr material series , we have greatly improved our products both in terms of quality and diversification. Currently , our product is widely used in a variety of applications , such as anti hydrogen-attack roll, ultra-deep hardened roll, anti-roll mark roll, anti-roll accident roll and the high wear resistance roll and so on.

brief introduction

|

Material

|

Carbon Steel , Alloy Steel

|

|

|

|

|||

|

Workplant

|

Forging , Casting and Welding

|

|

|

|

|||

|

Module of Gear

|

8-120

|

|

|

|

|||

|

Gear Grinding

|

MAX Module 25

|

|

|

|

|||

|

Diameter of Gear Wheel

|

MAX 13000 mm

|

|

|

|

|||

|

Diameter of Spiral Gear

|

MAX 2200 mm

|

|

|

|

|||

|

Length of Gear Shaft

|

MAX 5000 mm

|

|

|

|

|||

|

Segments Gear Offered

|

2parts,4parts,8parts,12parts or as customer requirement

|

|

|

|

|||

|

Gear Teeth treatment

|

Surface hardening,cemented and quenching

|

|

|

|

|||

Material

|

carbon steel

|

1010,20,35#,45#,16Mn,S355J2,SA350,A105,A266等

|

|

|

|

|||

|

Alloy steel

|

15CrMo,14Cr1Mo,20SiMn,18CrNiMo7-6,42CrMo4,34CrNiMo6,30CrNiMo8,4140,4340,F22等

|

|

|

|

|||

|

Mold steel

|

H11,H13

|

|

|

|

|||

|

Heat-resistant steel

|

1Cr13,2Cr13,F91,F92,X21CrMoV121,F6NM等

|

|

|

|

|||

|

stainless steel

|

304,321,316L,316LN,347, 310,F51,F44,F55,F53,F60,15-5PH,17-4PH,1Cr17Ni2等

|

|

|

|

|||

|

Nickel-based alloys

|

8810,8825,8120,GH4625,GH4169,GH4133、C276等

|

|

|

|

|||

|

Chinalloy

|

TC4、TC6、TC11

|

|

|

|

|||

Process Flow

Packaging&Delivery

Hot Searches