- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

China

-

Brand Name:

-

SINOTECH

-

Year:

-

2022

-

Power (kW):

-

11.7

-

Weight (KG):

-

1.2

-

Marketing Type:

-

New Product 2022

-

Keyword:

-

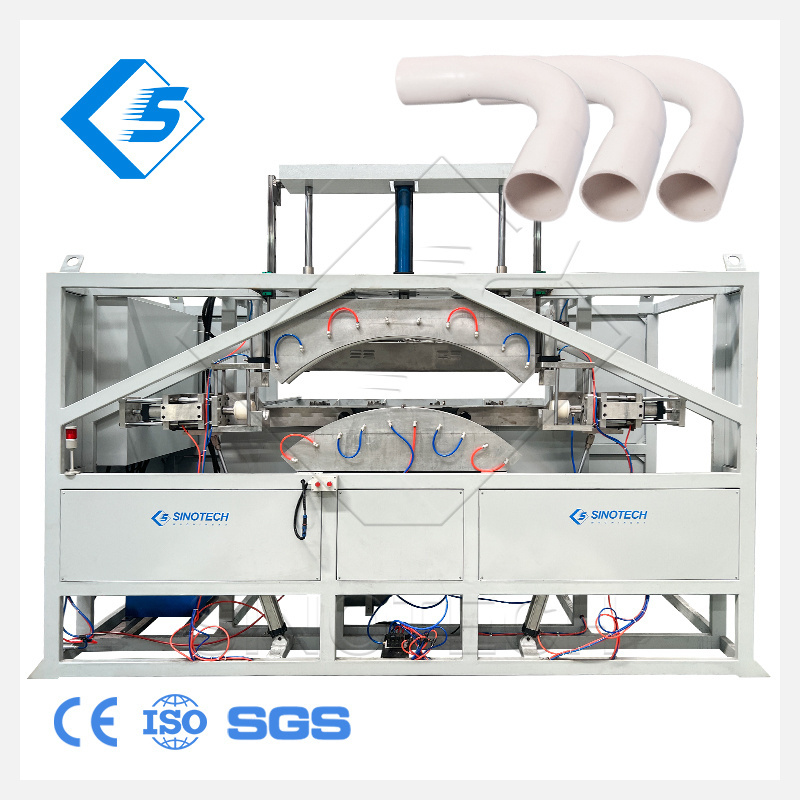

Automatic Plastic PVC pipe bender bending machine

-

Application:

-

plastic pipe bending

-

Type:

-

semi-auto

-

Voltage:

-

Customized

-

Bending speed:

-

20-100pcs each hour

-

Available bending pipe dia.:

-

20-160mm

-

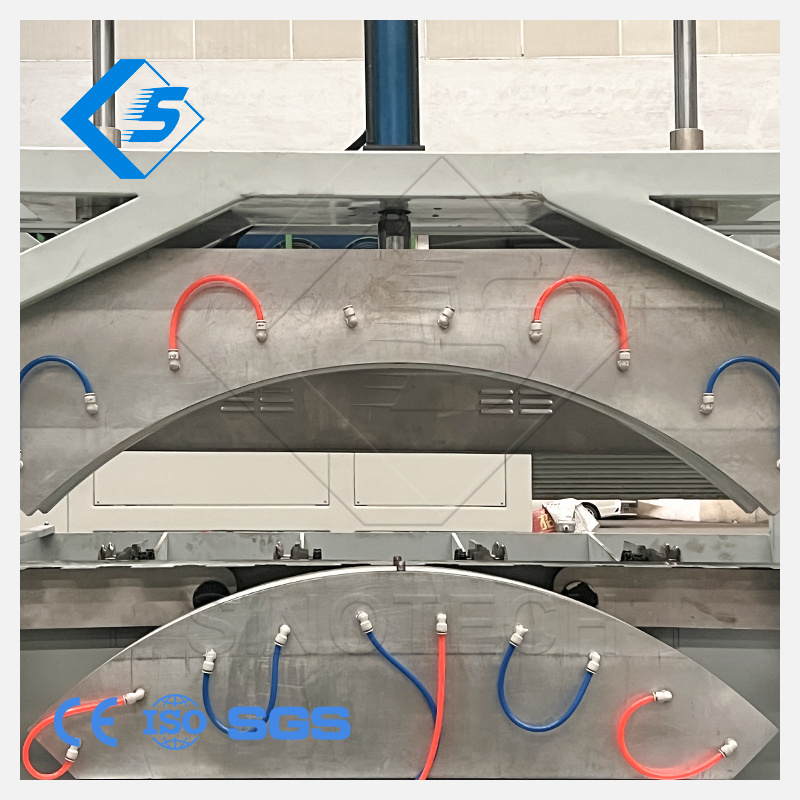

Heating Way:

-

Ceramic infrared heating

-

Available bending pipe length:

-

According to customer's request

-

Cooling type:

-

Air-cooling

-

After-sales Service Provided:

-

YES

Quick Details

-

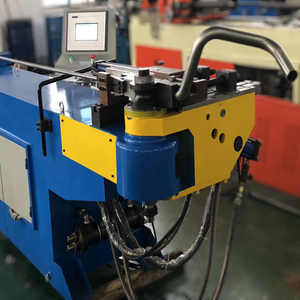

Machine Type:

-

pipe bending machine

-

Bending Radius (mm):

-

20 - 160

-

Max. Bending Angle (Deg):

-

90

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

China

-

Brand Name:

-

SINOTECH

-

Year:

-

2022

-

Power (kW):

-

11.7

-

Weight (KG):

-

1.2

-

Marketing Type:

-

New Product 2022

-

Keyword:

-

Automatic Plastic PVC pipe bender bending machine

-

Application:

-

plastic pipe bending

-

Type:

-

semi-auto

-

Voltage:

-

Customized

-

Bending speed:

-

20-100pcs each hour

-

Available bending pipe dia.:

-

20-160mm

-

Heating Way:

-

Ceramic infrared heating

-

Available bending pipe length:

-

According to customer's request

-

Cooling type:

-

Air-cooling

-

After-sales Service Provided:

-

YES

Product Description

Application

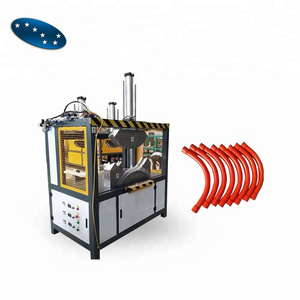

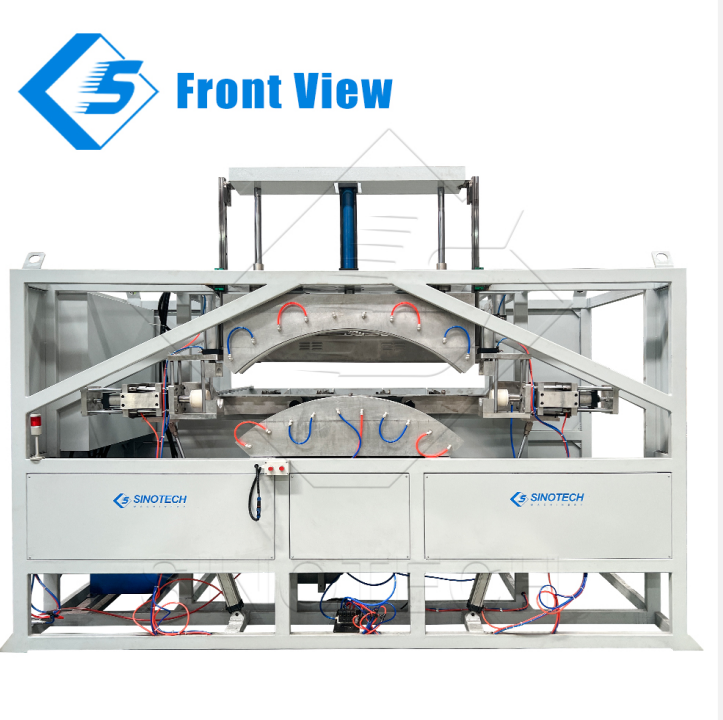

Manual type Semi-auto Plastic PVC Pipe Bending Machine

On the basis of internation advanced technology from the developed countries, we produced the PVC pipe bending machine independently. This machine can be used to replace traditional PVC fitting injection machines. And this machine can save cost about 50% than injection machines. We aim to make high quality machines with reasonable price.

This machine can bend the pipes at the same time of making socket.

This machine can bend the pipes at the same time of making socket.

Function

- Bend PVC pipes.

- Bend and socketing PVC pipe in one end.

- Bend and socketing PVC pipes in both ends

Main advantages:

- PERFECT ROUNDNESS of the entire bend;

- HIGH OUTPUT;

- Length, angle and radius of the bends are variable;

- High level of technology;

- User-friendly machine;

- Reliability, efficiency, low maintenance;

- Compact machine - small size.

- Bend PVC pipes.

- Bend and socketing PVC pipe in one end.

- Bend and socketing PVC pipes in both ends

Main advantages:

- PERFECT ROUNDNESS of the entire bend;

- HIGH OUTPUT;

- Length, angle and radius of the bends are variable;

- High level of technology;

- User-friendly machine;

- Reliability, efficiency, low maintenance;

- Compact machine - small size.

|

Main Technical Parameters

|

|

|

|

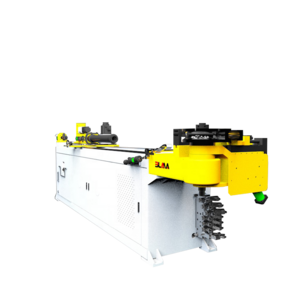

Model

|

SNBL-32

|

|

|

Suitable pipe range

|

16-32mm

|

|

|

Machine type

|

Semi-auto pvc pipe bending machine

|

|

|

Pipe length

|

According to customer's request

|

|

|

Pipe material

|

PVC

|

|

|

Air Pressure

|

0.4-0.6Mpa

|

|

|

Machine speed

|

20-30pcs/hr

|

|

|

Oil Pump motor

|

4KW

|

|

|

Max.heating temperature

|

450ºC

|

|

|

Heating Method

|

Ceramic infrared heating

|

|

|

Heating power

|

17.5KW

|

|

|

Heating station

|

1

|

|

|

Cooling method

|

Air cooling and water cooling

|

|

|

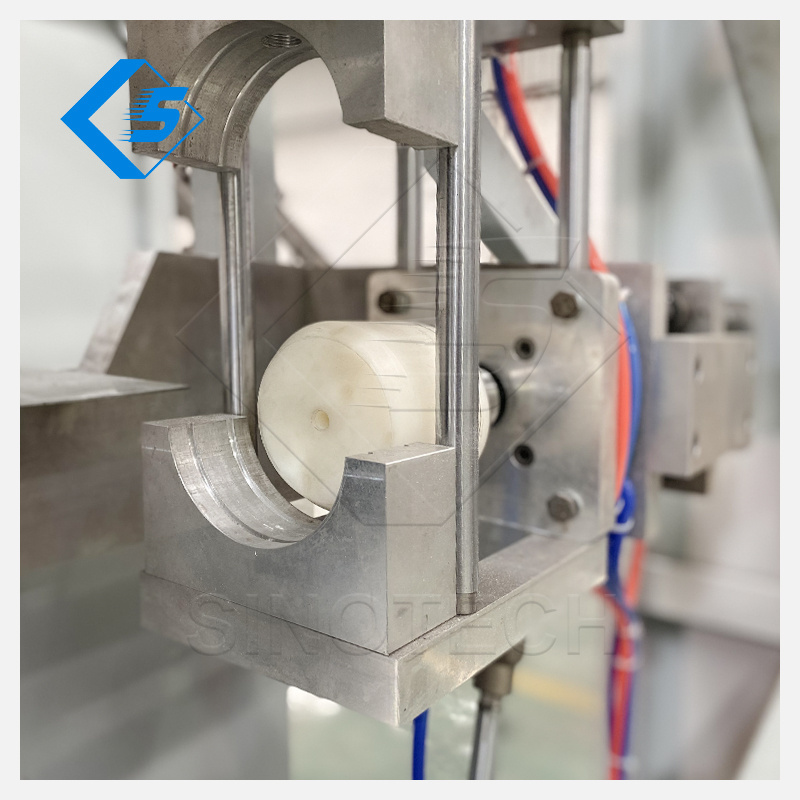

Socketing station

|

1x1

|

|

|

hydrailic oil

|

46# wear resistance hydraulic oil

|

|

|

Required water pressure

|

0.2-0.3Mpa

|

|

|

Socket type

|

U type and R type

|

|

|

Machine size(LxWxH)

|

3050x2300x2080mm

|

|

|

Machine weight

|

1.2T

|

|

|

Bending angle

|

45degree/60degree/90degree/120degree

|

|

|

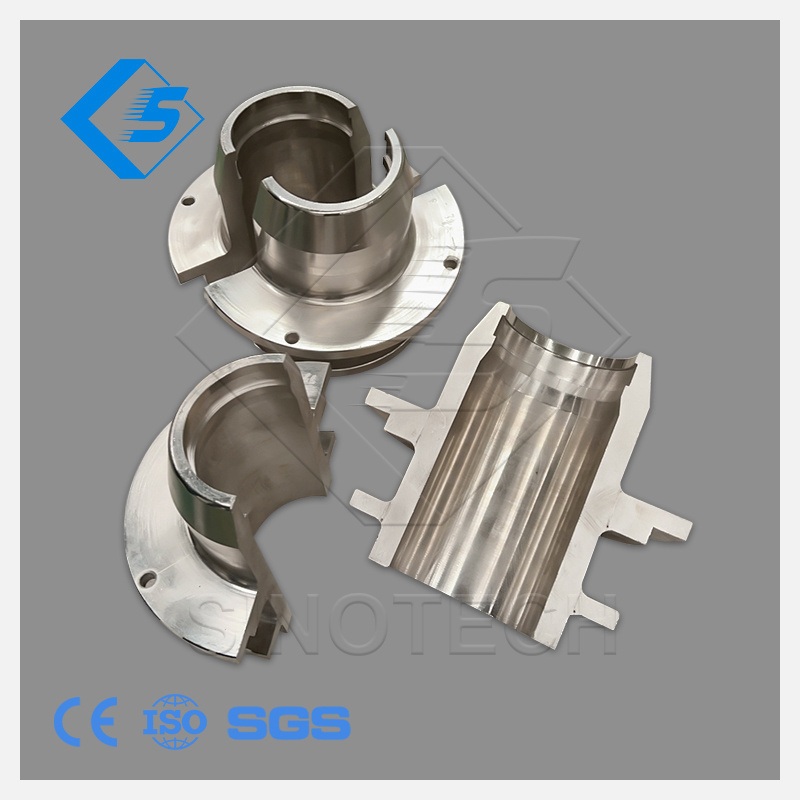

Bend mold

|

Aluminum

|

|

|

Socket mold:

|

45# steel with Cr electroplating

|

|

|

This machine can bend 1pcs of pipe each time

|

|

|

Seller Recommendation

Application

Hot Searches