- Product Details

- {{item.text}}

Quick Details

-

Panel Dimensions:

-

1200*600

-

Panel Efficiency:

-

19%

-

Function:

-

power generation

-

Technique:

-

thin-film

-

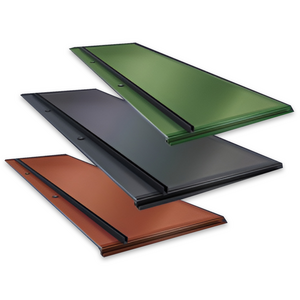

Colors:

-

grey or customized

-

Size:

-

1200*600mm

-

Thickness:

-

6.9mm

-

Shape:

-

Flat

-

Structure:

-

Solid

-

Packing:

-

Wooden case

-

Uesag:

-

BIPV, ROOF, ETC.

Quick Details

-

Brand Name:

-

Vatti Glass

-

Model Number:

-

Solar Panel

-

Place of Origin:

-

Shandong, China, Shandong China (Mainland)

-

Panel Dimensions:

-

1200*600

-

Panel Efficiency:

-

19%

-

Function:

-

power generation

-

Technique:

-

thin-film

-

Colors:

-

grey or customized

-

Size:

-

1200*600mm

-

Thickness:

-

6.9mm

-

Shape:

-

Flat

-

Structure:

-

Solid

-

Packing:

-

Wooden case

-

Uesag:

-

BIPV, ROOF, ETC.

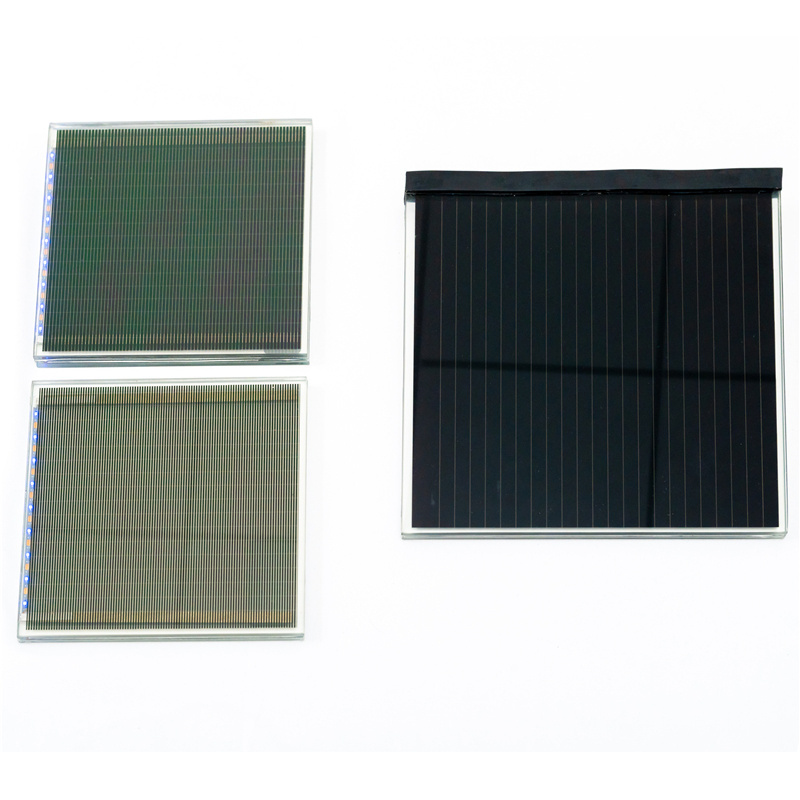

Products Description

CdTe thin-film solar panels are comprised of three main parts, having a layer for the semiconductor, one for the protection, and one for the conduction. These parts are:

* Photovoltaic material

* Photovoltaic material

The photovoltaic material is the part of the CdTe thin-film solar panel that converts solar radiation into DC energy. This is

manufactured by creating a p–n heterojunction, this semiconductor requires the deposition of a layer of CdTe for the p-doped section and one of CdS or MZO for the n-doped section.

* Conductive sheet

The conductive sheet allows the DC energy to flow between solar cells, increasing the voltage and allowing for the connection of CdTe panels into photovoltaic (PV) systems. These layers require the deposition of a metal layer or carbon paste, introducing

copper (Cu) to create conduction in the panel.

* Protective layer

Photovoltaic layers tend to be very fragile, which is why thin-film solar panels require a protective layer. Instead of using an

aluminum frame and tempered glass, this layer known as the Transparent Conductive Oxide (TCO) layer, is made by depositing SnO2:F or a similar material. The TCO layer is where the CdTe absorber is deposited, allowing the solar cell to be fully protected.

manufactured by creating a p–n heterojunction, this semiconductor requires the deposition of a layer of CdTe for the p-doped section and one of CdS or MZO for the n-doped section.

* Conductive sheet

The conductive sheet allows the DC energy to flow between solar cells, increasing the voltage and allowing for the connection of CdTe panels into photovoltaic (PV) systems. These layers require the deposition of a metal layer or carbon paste, introducing

copper (Cu) to create conduction in the panel.

* Protective layer

Photovoltaic layers tend to be very fragile, which is why thin-film solar panels require a protective layer. Instead of using an

aluminum frame and tempered glass, this layer known as the Transparent Conductive Oxide (TCO) layer, is made by depositing SnO2:F or a similar material. The TCO layer is where the CdTe absorber is deposited, allowing the solar cell to be fully protected.

|

Product

|

CdTe Solar Panels

|

|

Temperature Coefficient

|

-0.172%/ºC

|

|

Efficiency

|

19%

|

|

Compatibility With Inverters

|

Installers have to consider temperatures at the installation place concerning temperature coefficient

|

|

Required Space

|

Require up to 31% more space per kW installed

|

|

Applications

|

Commercial/Industrial

|

|

Size

|

1200*600mm

|

|

Transmittance

|

0%, 20%, 40%, 50%

|

|

Power/piece(wp)

|

105w, 80w, 60w, 50w

|

|

Power generation (degree/sqm)

|

170, 135, 105, 85

|

|

Junction Box

|

Back, side, cable 2.5mm², 650±10mm

|

|

Connectors

|

MC4

|

Application Scenario

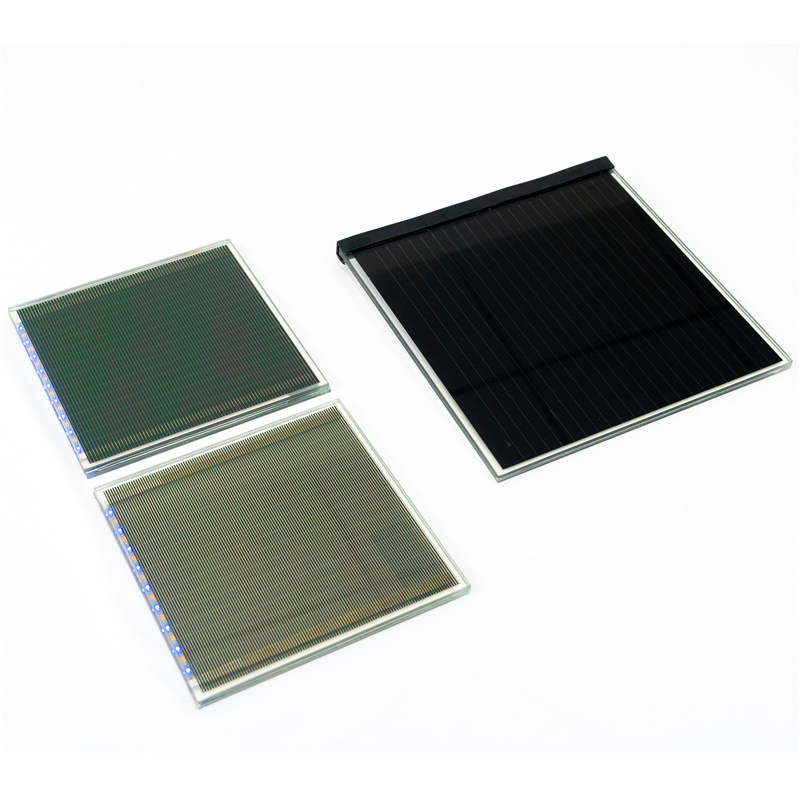

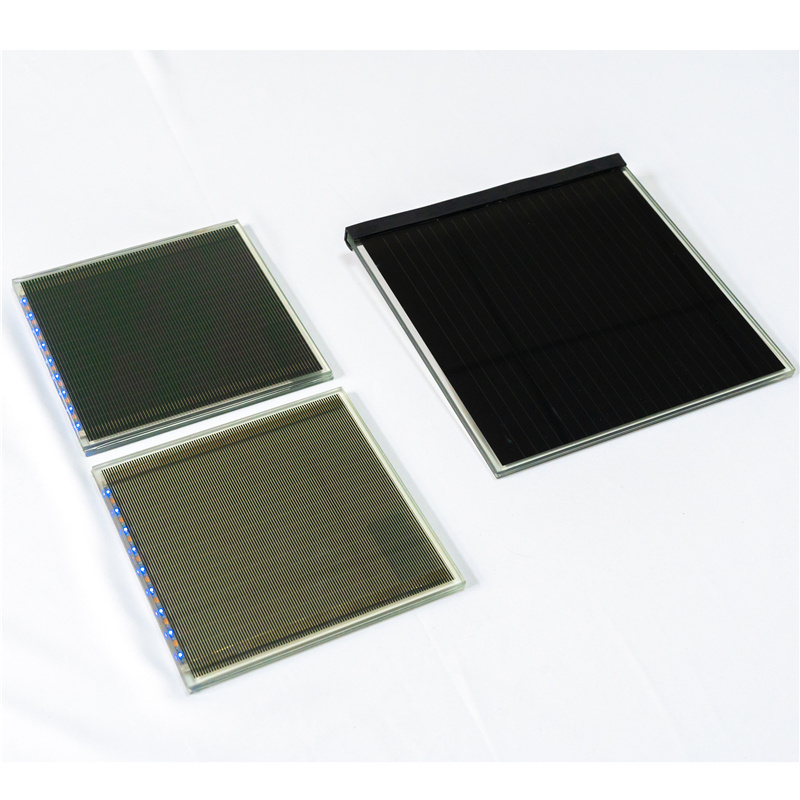

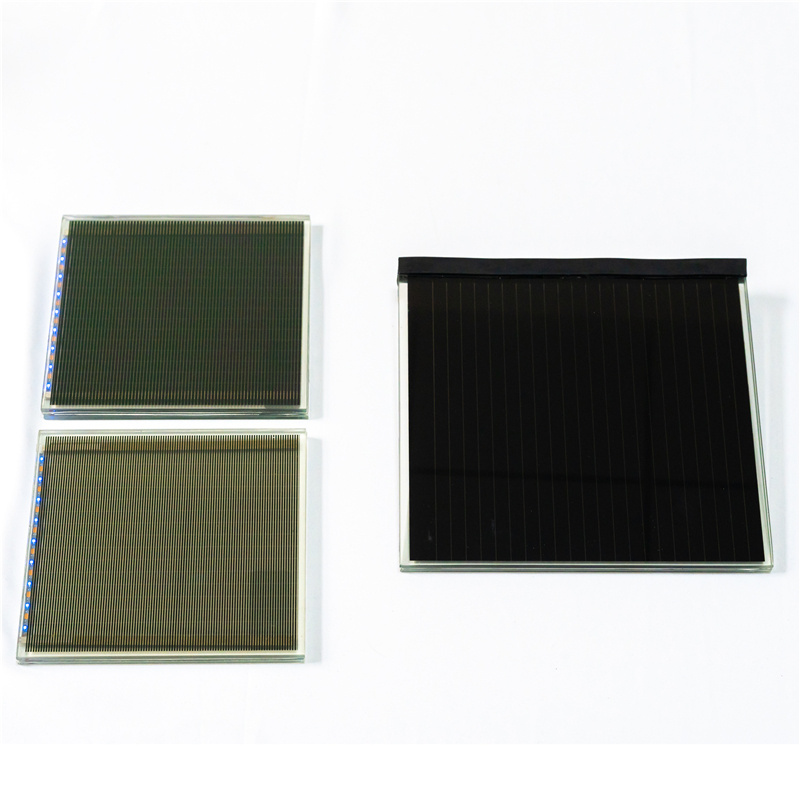

Picture Show

VATTI GLASS

High Quality CdTe Solar Panel For You to Choose

VATTI GLASS

Professional Technical Support for your Solar Panel System

Similar Items

Working Process

Packing Details

Hot Searches