- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.1

-

Thickness:

-

Customizable

-

Width:

-

Customizable

-

Length:

-

Customizable

-

Working Temperature:

-

300-1600

-

Shrinkage (1800℉, 3h):

-

1%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

JY-CH-01

-

Brand Name:

-

JINYU

-

Heating element:

-

FeCrAL, NiCr resistance wire

-

Max. temperature:

-

1300C

-

Shape:

-

Customizable

Quick Details

-

Chemical Composition:

-

alumina-silica fiber

-

Ultimate Strength (≥ MPa):

-

0.3

-

Fiber Diameter:

-

3-5um

-

Thermal Conductivity:

-

0.1

-

Thickness:

-

Customizable

-

Width:

-

Customizable

-

Length:

-

Customizable

-

Working Temperature:

-

300-1600

-

Shrinkage (1800℉, 3h):

-

1%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

JY-CH-01

-

Brand Name:

-

JINYU

-

Heating element:

-

FeCrAL, NiCr resistance wire

-

Max. temperature:

-

1300C

-

Shape:

-

Customizable

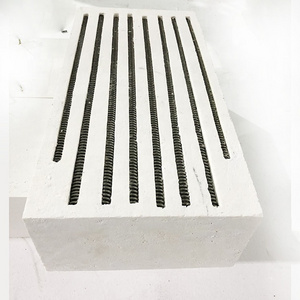

Ceramic Fiber Heaters for Muffle Furnace with Resistance Wire Heating Element

-- Ceramic Fiber Heater combines a heat source with superior high

temperature insulation - an ideal solution for many industrial heating applications. These heaters deliver fast, efficient and reliable uniform heat to

temperature of 1250°. Designed to deliver power densities up to 1500

watts/ft2, we are one of the most versatile embedded element radiant

heaters produced. OEM furnace and thermal process equipment manufacturers plus end users alike have embraced this combination heating and insulating system.

-- Flat Panel, Full Cylinder and Semi-Cylinder Ceramic Fiber Insulated Heaters consist of high quality helically-wound Fe-Cr Al alloy resistance wire elements embedded in a rigid body of vacuum formed high temperature refractory fiber. The lightweight ceramic fiber insulation has very low thermal mass and thermal conductivity and thus can handle extremely rapid cycling. Elements are typically mounted flush with the heated surface. The diameter of the helically wound element coil is kept to a minimum, reducing the difference between the element and chamber temperature, thus ensuring long heater life, and enabling the design and manufacture of extremely responsive heating systems.

--All Fiber Insulated Heaters are 100% organic free and will not smoke or outgas when heated. Fiber Insulated Heaters are available in flat panel, full cylinder and semi-cylinder shapes - with several lead styles.

-- Ceramic Fiber Heater Characteristics:

|

Thermal Response Power (watts) plus Hot & Cold Face Temperatures (°C) vs. Time for a test furnace composed of a custom cylindrical heater (6in. ID x 10in. OD x 6in. L, 1200W, 120V) with 2in. thick Alumina-Silica Insulation Type AXL discs on each end. |

|

|

Electrical Change The electrical characteristics of these heaters change with temperature due to a shift in resistivity of the alloy use in the heating coil. At 1100C there is a ~3.8% increase in resistance and decrease in current and power. |

|

|

Safe Operation Zone Fiber Insulated Heaters Type FIH are designed to operate at power densities up to 1500 watts/ft2 at 1100C. They may, however operate at significantly higher power densities at lower temperatures and still provide long life.

|

|

-- Ceramic Fiber Heater Availability:

|

ITEM |

DESCRIPTION |

SHIP WT. (lb.) |

|

1 |

C, 1in. x 3in. x 6in., 200w, 60V |

5 |

|

2 |

C, 3in. x 6in. x 12in., 1200w, 120V |

8 |

|

3 |

C, 8in. x 12in. x 12in., 3100w, 240V |

12 |

-- Ceramic Fiber Insulated Heaters Specification:

Typically manufactured to customer specification, we can design and construct unit’s tosatisfy a range of heating needs.

|

Flat panel heaters are typically produced up to 36in. wide x 48in. long x 6in. thick. Custom heaters and shapes Smaller than a few cubic inches and larger than several cubic feet have been produced.

Cylindrical heaters typically produced have 1in. to 24in.ID, 1in. to 4in. wall thickness and are up to 12in. long. Custom cylindrical units and shapes smaller than a few cubic inches, larger than several cubic feet, weighing up to 100 pounds, with ID’s of 1/2in. to 36in., wall thickness of 1/2in.’ to 6in. and lengths to 48in. can be produced. Staved cylinder heaters typically produced have 24in. to 84in.ID, 1in. to 5in. wall thickness and segments up to 24in. long. Shapes smaller than a few cubic inches, larger than several cubic feet, with ID’s of 1in. and up, wall thickness of 1/2in. to 6in. and lengths to 48in. can be produced. |

-- Ceramic Fiber Heater Application:

Applications include semiconductor production, gem production, laboratory and research, annealing, sintering, heat treating, metal melting .

Packaging:

Standard export packaging or as bcustomer's request.

Shipping:

We could supply you the follow shipping way for your choice:

--By DHL/Fedex (Door to door, Home delivery service)

--By Air to your nearest Airport

--By Sea to your nearest Seaport

--By the sellers’ shipping agent