- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ADV

-

Dimension(L*W*H):

-

8000*2000*1800 mm

-

Weight:

-

4000 KG

-

Product name:

-

Multifunctional automatic laminating machine

-

Cutting blade:

-

Tungsten steel knife/nickel wire

-

Power lack length:

-

4500 mm

-

unpowered material rack length:

-

2500 mm

-

Running speed:

-

5-20 m/min

-

Processing board length:

-

500-3500 mm

-

Servo motor power:

-

1.2*2 kw

-

Material rack motor power:

-

1.5 kw

-

Number of rubber rollers:

-

6

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic, Metal, Glass, Wood

-

Driven Type:

-

Electric

-

Voltage:

-

380V

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ADV

-

Dimension(L*W*H):

-

8000*2000*1800 mm

-

Weight:

-

4000 KG

-

Product name:

-

Multifunctional automatic laminating machine

-

Cutting blade:

-

Tungsten steel knife/nickel wire

-

Power lack length:

-

4500 mm

-

unpowered material rack length:

-

2500 mm

-

Running speed:

-

5-20 m/min

-

Processing board length:

-

500-3500 mm

-

Servo motor power:

-

1.2*2 kw

-

Material rack motor power:

-

1.5 kw

-

Number of rubber rollers:

-

6

Machine Parameters

|

Product name

|

Multifunctional flat automatic laminating machine

|

|

Voltage/power

|

380V 4KW

|

|

Packaging material

|

plastic, metal, Glass,wood

|

|

Running speed

|

5-20 m/min

|

|

Cutting blade

|

Tungsten steel knife/Nickel wire

|

|

Processing board width

|

Available 1250mm/1500mm wide

|

|

Processing board thickness

|

0.5-30 mm

|

|

Processing board length

|

800-3500 mm

|

|

power rack length

|

4500 mm

|

|

unpowered material rack length

|

2500 mm

|

|

Upper and lower rubber roller diameter

|

120 mm

|

|

Number of rubber roller

|

6

|

Product description

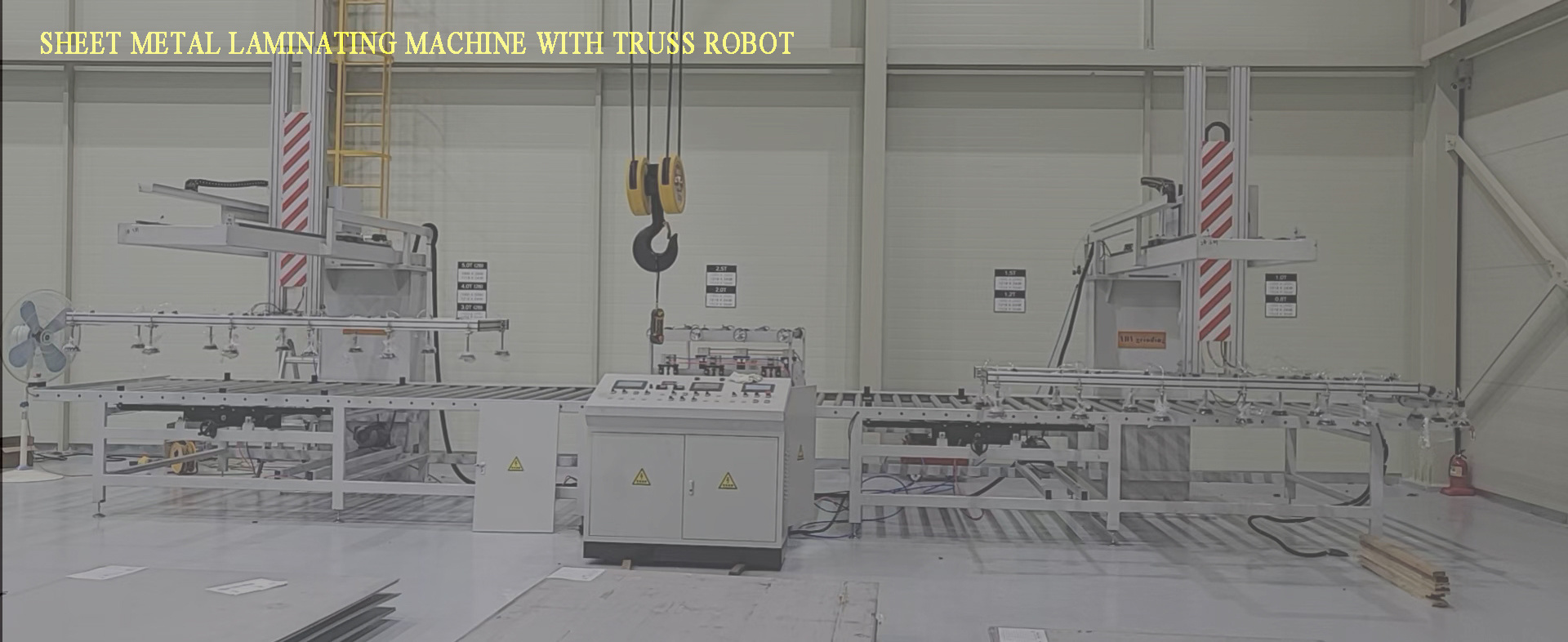

Automatic Truss Manipulator for loading

Automatic Truss Manipulator for unloading

Equipment description:

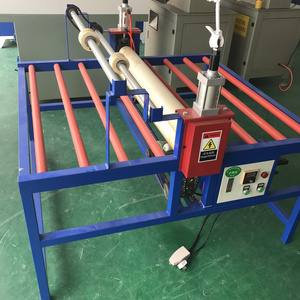

1.Used to coat flat metal plates (aluminum, copper, stainless steel, etc.), glass, MDF plates, wood board and other materials.The laminating machines are designed to cover with a plastic film on a finished surface in order to protect it from dust, scratches and damages that can occur during handling and forming operations.

2. The frame is welded by the national standard 125×125H steel;

3. Independent control cabinet, touch screen, extremely simple operation, manual and automatic switching at

will, flexible and convenient;

4. Programmable PLC, controller and infrared sensor accurately control the servo motor with planetary reducer and pneumatic components to automatically complete a series of actions such as position detection, feeding, filming, and cutting of the sheet.Make the mechanical operation more humane.

2. The frame is welded by the national standard 125×125H steel;

3. Independent control cabinet, touch screen, extremely simple operation, manual and automatic switching at

will, flexible and convenient;

4. Programmable PLC, controller and infrared sensor accurately control the servo motor with planetary reducer and pneumatic components to automatically complete a series of actions such as position detection, feeding, filming, and cutting of the sheet.Make the mechanical operation more humane.

Our Advantages

Equipment advantages:

1. After the machine is loaded, the distance between the two materials is automatically adjusted;

2. Cutting device, adjustable speed, easy blade replacement;

3. The equipment is suitable for single-sided and double-layer filming of the sheet, and it is automatically cut;

4. Precise induction, cutting accuracy of ±1mm.

5.intelligent control system,interactive man-machine interface

6. Reverse function before and after laminating

7. Low noise operation, high sensitivity

8. All parts of the machinery adopt the products of famous and excellent manufacturers

9. Can work in cold and low temperature conditions

2. Cutting device, adjustable speed, easy blade replacement;

3. The equipment is suitable for single-sided and double-layer filming of the sheet, and it is automatically cut;

4. Precise induction, cutting accuracy of ±1mm.

5.intelligent control system,interactive man-machine interface

6. Reverse function before and after laminating

7. Low noise operation, high sensitivity

8. All parts of the machinery adopt the products of famous and excellent manufacturers

9. Can work in cold and low temperature conditions

Why Choose Us

What kind of support you can get from ADV GRINDING?

1. 3 year warranty, provide a full range of technical support for life.

1. 3 year warranty, provide a full range of technical support for life.

2.From

monday to sunday 9am to 22pm

.Experienced technician to guarantee lifetime online support(by whatsapp /skyper /wechat/email).So there is no need to worry about technical support due to time difference.

3.Support local after-sales service. up to 2021, we have offered onsite to these countries and areas: Canada, Mexico, the United States, Ukraine, Russia, Italy, Poland, Spain, Brazil, Indonesia, India, Turkey, Thailand, Vietnam, Australia,etc.

3.Support local after-sales service. up to 2021, we have offered onsite to these countries and areas: Canada, Mexico, the United States, Ukraine, Russia, Italy, Poland, Spain, Brazil, Indonesia, India, Turkey, Thailand, Vietnam, Australia,etc.

Hot Searches