Biomass carbonization is a process that involves heating biomass, such as wood, agricultural waste, or other organic matter, in the absence of oxygen to produce a high-carbon content material known as biochar. This process is also known as pyrolysis, and it can be done using various methods, including slow pyrolysis, fast pyrolysis, and torrefaction.

During the process of biomass carbonization, the biomass is heated to temperatures ranging from 300 to 800 degrees Celsius. This causes the organic matter to break down into gases, liquids, and solids. The gases and liquids are typically collected and used as fuel, while the solid residue, which is mainly carbon, is collected as biochar.

- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

3

-

Dimension(L*W*H):

-

45m*15m*7m

-

Voltage:

-

Customized

-

Power:

-

47.5kw

-

Weight (KG):

-

25000

-

Raw material:

-

Coconut Shell Wood Sawdust Briquette

-

Product name:

-

Carbonization Furnace

-

Fuel:

-

Biomass Pellet, Diesel, Natural Gas

-

Final product:

-

Charcoal Bio-char Wood vinegar

-

Material:

-

304 Stainless Steel

-

Capacity:

-

2T/hour

-

Aftersale service provided:

-

24 Hour Online

-

Control Cabinet:

-

PLC Automatic Control Cabinet

-

Feature:

-

Continuous Machine

-

Color:

-

Customer's Request

Quick Details

-

Place of Origin:

-

HEN

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

MINGJIE

-

Effective Volume:

-

3

-

Dimension(L*W*H):

-

45m*15m*7m

-

Voltage:

-

Customized

-

Power:

-

47.5kw

-

Weight (KG):

-

25000

-

Raw material:

-

Coconut Shell Wood Sawdust Briquette

-

Product name:

-

Carbonization Furnace

-

Fuel:

-

Biomass Pellet, Diesel, Natural Gas

-

Final product:

-

Charcoal Bio-char Wood vinegar

-

Material:

-

304 Stainless Steel

-

Capacity:

-

2T/hour

-

Aftersale service provided:

-

24 Hour Online

-

Control Cabinet:

-

PLC Automatic Control Cabinet

-

Feature:

-

Continuous Machine

-

Color:

-

Customer's Request

Products Description

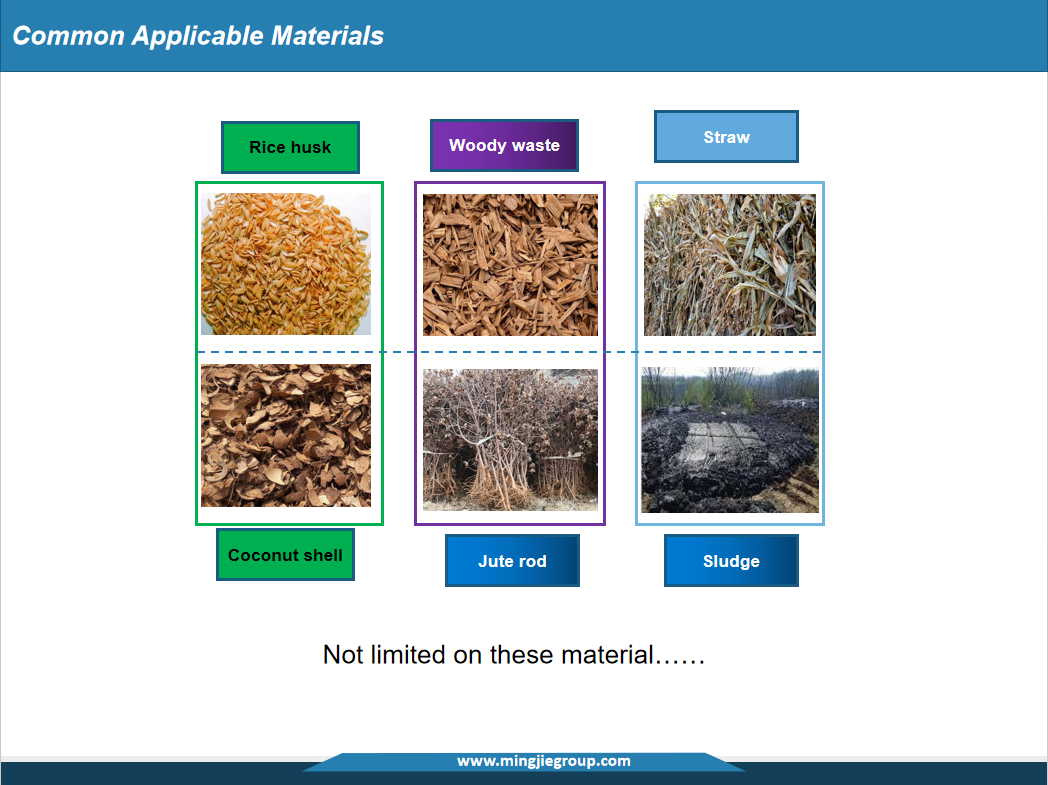

Applicable Materials

Model for Choose

|

Model

|

MJT-500

|

MJT-1000

|

MJT-2000

|

MJT-3000

|

|

Reactor Structure

|

Dual Cylinder

|

Dual Cylinder

|

Dual Cylinder

|

Dual Cylinder

|

|

Reactor Material

|

304 Stainless Steel

|

304 Stainless Steel

|

304 Stainless Steel

|

304 Stainless Steel

|

|

Input Capacity

|

300-500KG/H

|

800-1000KG/H

|

1500-2000KG/H

|

2500-3000KG/H

|

|

Feedstock size

|

<20mm

|

<20mm

|

<20mm

|

<20mm

|

|

Feedstock moisture

|

<15%

|

<15%

|

<15%

|

<15%

|

|

Charcoal output ratio

|

28-35%

|

28-35%

|

28-35%

|

28-35%

|

|

Working Method

|

Fully Continuous

|

Fully Continuous

|

Fully Continuous

|

Fully Continuous

|

|

Fuel Consumption

|

35-50m³ Natural Gas for initial Heating

|

40-60m³ Natural Gas for initial Heating

|

60-80m³ Natural Gas for initial Heating

|

80-100m³ Natural Gas for initial Heating

|

|

Land required

|

L35*W12*H6m

|

L35*W12*H7m

|

L45*W15*H7m

|

L45*W15*H7m

|

Final Product & Application

Biochar/Charcoal

Used as soil conditioner, carbon sequestration, improve the quality of soil

Used as fuel for industry heating and cooling or BBQ

Can be reprocessed into activated carbon, widely used in the smelting, chemical fields.

Tar&Wood Vinegar

Widely used as a crop insecticide, make leaf surface fertilizer

Syngas

Can be recycled to heat the carbonization host.

By this way, you can reduce a lot of fuel costs.

Hot Searches