- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±6mm

-

Voltage:

-

220v

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEM

-

Dimension(L*W*H):

-

Adjustable

-

Weight:

-

KG

-

Washing heads:

-

18

-

Filling heads:

-

18

-

Capping heads:

-

6

-

Capacity:

-

3000BPH-4000BPH

-

Air consumption:

-

0.15m3/min(0.4~0.6Mpa)

-

CO2 consumption:

-

1.6kg/l000L

-

Water consumption:

-

0. 8m3/h

-

Touch screen:

-

PLC

-

Vacuum pump:

-

0. 20m3/h

-

Frequency converter:

-

SIEMEMS

Quick Details

-

Machinery Capacity:

-

4000BPH, 2000BPH, 3000BPH

-

Packaging Material:

-

Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Juice

-

Filling Accuracy:

-

±6mm

-

Voltage:

-

220v

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEM

-

Dimension(L*W*H):

-

Adjustable

-

Weight:

-

KG

-

Washing heads:

-

18

-

Filling heads:

-

18

-

Capping heads:

-

6

-

Capacity:

-

3000BPH-4000BPH

-

Air consumption:

-

0.15m3/min(0.4~0.6Mpa)

-

CO2 consumption:

-

1.6kg/l000L

-

Water consumption:

-

0. 8m3/h

-

Touch screen:

-

PLC

-

Vacuum pump:

-

0. 20m3/h

-

Frequency converter:

-

SIEMEMS

big Capacity 18-18-6 Beer Bottle Rinsing Filling Capping Unit Machine

|

Item

|

Parameters

|

Item

|

Parameters

|

|

Washing heads

|

18

|

Vacuum pump

|

0. 20m3/h

|

|

Filling heads

|

18

|

Power

|

main motor: 1.5KW

hopper motor: 0 .18KW vacuum pump motor:1.1KW chain motor: 0.75KW |

|

Capping heads

|

6

|

Dimensions

|

Accoring to the machine

|

|

Capacity

|

3000BPH-4000BPH

|

N.W.

|

3000kg

|

|

Bottle type

|

height:150~ 300mm

bottle neck:50~85mm bottle diameter: 50-75mm |

Working voltage AC

|

It can be customized by the customers'electrical conditions.

|

|

Air consumption

|

0.15m3/min(0.4~0.6Mpa)

|

Control voltage DC

|

It can be customized by the customers'electrical conditions.

|

|

CO2consumption

|

1.6kg/l000L

|

Frequency converter

|

SIEMEMS

|

|

Water consumption

|

0. 8m3/h

|

PLC

|

SIEMEMS

|

|

Touch screen

|

PLC

|

Pneumatic element

|

SMC

|

Product Description :

The 18 heads filling machine designed by HG Company adopts the counter pressure filling technology which can perfectly realize the requirments of twice vacuum, Co2 injection. The machinealso adopts 3 in 1 compact design, easy to operate and maintain..

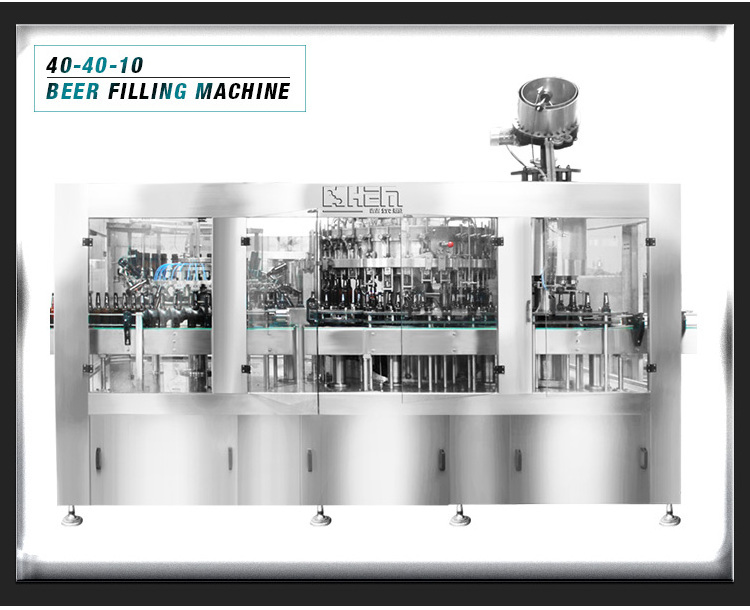

40-40-10 Glass Bottle Beer Filling Machine

The machine is adopts counter pressure filling technology, this machine is specially designed for beer filling.

The machine has the advantages of high speed, reliable output, compact design and stable operation. The

machine suitable for medium or large capacity breweries.

The machine has the advantages of high speed, reliable output, compact design and stable operation. The

machine suitable for medium or large capacity breweries.

16-16-6 Glass Bottle Beer Filling Machine

The 16 heads filling machine designed by HEM Company adopts the counter pressure filling technology which

can perfectly realize the requirments of twice vacuum, Co2 injection. The machinealso adopts 3in 1 compact

design, easy to operate and maintain.

can perfectly realize the requirments of twice vacuum, Co2 injection. The machinealso adopts 3in 1 compact

design, easy to operate and maintain.

6-6-1 Glass Bottle Filling Machine

6-6-1 type beer bottle washing filling capping monoblock is designed combined with the actual situation in

our country after the introduction and absorption that comes from Germany technologies. It adopts isobaric

filling principle and filling valve adopts high precision mechanical valve. It has advantages of taking small

space, high precision in liquid level. Adopt Siemens automatic controlling system, realizing trinity of the

machines, and control the rinsing , filling and capping process.

our country after the introduction and absorption that comes from Germany technologies. It adopts isobaric

filling principle and filling valve adopts high precision mechanical valve. It has advantages of taking small

space, high precision in liquid level. Adopt Siemens automatic controlling system, realizing trinity of the

machines, and control the rinsing , filling and capping process.

Advantage :

1). The machine is our patent product.

2). The machine adopts the counter pressure filling technology which can realize the requirements of twice vacuum, co2 injection.

3). The machineadopts 3 in 1 compact design, easy to operate and maintain.

4). Using the external filling valve can ensure the quality of beer Using mechanical gland instead of pneumatic gland improves the quality and stability of gland. All mechanical transmission, basically reaching zero failure rate.

5). Two times of vacuumizing and two times of carbon dioxide filling can minimize the amount of oxygen dissolved and maintain the taste of beer. Equal pressure filling makes the filling process more stable.

6).The application of the sensor realizes filling only when there is bottle, no bottle, no filling, and the beer scrap rate is less than 0.8%. All cables are installed on the top of the equipment, making it safer to use.

|

Item

|

Production capacity

|

Filling method

|

Material

|

Dimensions

|

|

HEM-4-4-1

|

240-360BPH

|

Isobaric filling

|

SUS304

|

1550*550*1750mm

|

|

HEM-6-6-1

|

500-800BPH

|

Isobaric filling

|

SUS304

|

1520*1125*2350mm

|

|

HEM-8-8-3

|

800-1000BPH

|

Isobaric filling

|

SUS304

|

1850*1600*2500mm

|

|

HEM-16-16-6

|

2000BPH

|

Isobaric filling

|

SUS304

|

2300*1900*2500mm

|

|

HEM-40-40-10

|

8000-10000BPH

|

Isobaric filling

|

SUS304

|

4200*3000*2700mm

|

1.Q:Does your company have foreign installation experience?

A: Yes, our company has installation experience in USA, Canada, Europe, Australia, Malaysia, Myanmar, South Africa etc.

2.Q: Do you have a professional engineer or after-sales team in our country?

A: Yes, our equipment is sold to 150 countries and areas and we have our local after-sales service personnel in Europe, America and Asia.

3.Q:How can you guarantee the delivery date of the equipment after we place the order?

A: The delivery time can be ensured through Alibaba Credit Insurance orders.

4.Q:What payment methods are supported?

A:T/T, L/C, Credit Card, VISA, Apple device, Western Union.

5. Q: How long the warranty will be?

A: 3 years warranty for the whole tank and the main equipment, 1 year for the accessories and auxiliaries. 1 Year warranty for filling machine.

6.Q: How about the installation and training?

A: We can supply the installation and training. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

7.Q: Can I be your company's sales agent?

A: Yes, it’s our pleasure. We very much welcome you to join us. Please contact us to discuss specific details.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches