- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-415V

-

Power:

-

400-600KW

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

1600

-

Spray Painting Booth:

-

side draft

-

Clean Room:

-

Clean Class 10,000

-

Flooring:

-

Epoxy floor

-

IR Oven:

-

50-80 degree adjustable

-

UV Oven:

-

1000-1200mj/cm2

-

Oven MOC:

-

50mm thermal panel

-

Process:

-

Basecoat + Topcoat

-

Air Handling Unit:

-

humidity 60-65%, temperature 25-27 degree

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machine Type:

-

Automatic UV Spray Coating Machine, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Other

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HLC

-

Voltage:

-

380-415V

-

Power:

-

400-600KW

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

1600

-

Spray Painting Booth:

-

side draft

-

Clean Room:

-

Clean Class 10,000

-

Flooring:

-

Epoxy floor

-

IR Oven:

-

50-80 degree adjustable

-

UV Oven:

-

1000-1200mj/cm2

-

Oven MOC:

-

50mm thermal panel

-

Process:

-

Basecoat + Topcoat

-

Air Handling Unit:

-

humidity 60-65%, temperature 25-27 degree

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

Automatic UV PVD Coating Machine for Plastic Parts

| Power | 380-415V,3-phase,50Hz |

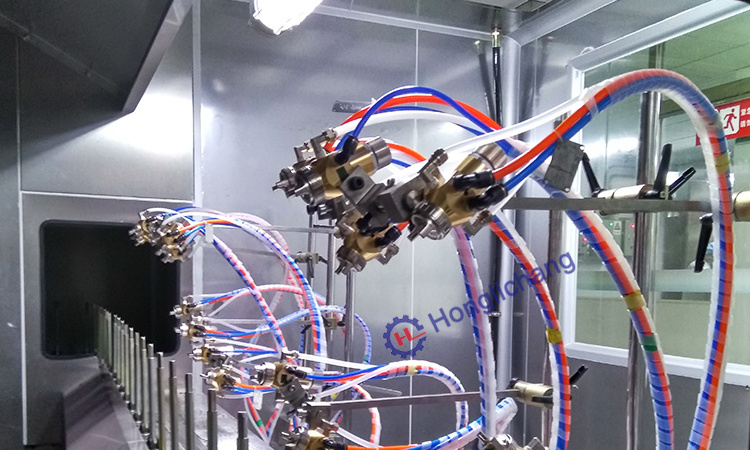

| Spindle Conveyor |

|

| Deionizing Booth |

|

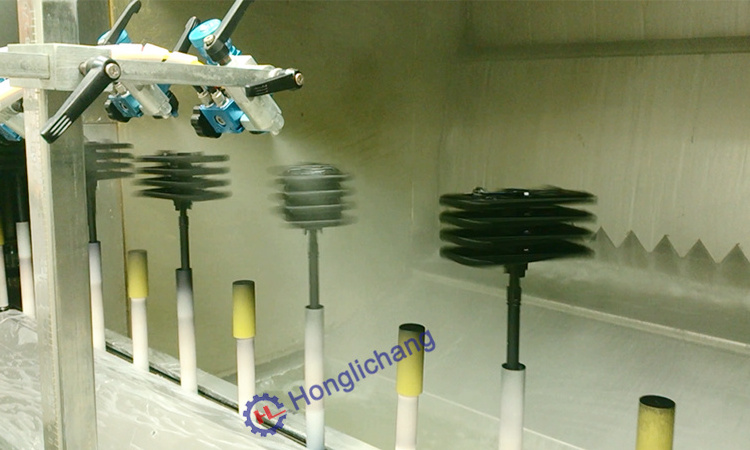

| Spray Booth |

|

| Rotation Unit |

|

| Oven |

|

| Control Panel |

|

|

Air Handling Unit |

|

|

Coiling Air-conditioning |

|

1. Clean Class: 10K for painting booth & paint kitchen; 100K for oven zones, loading/unloading area and passage.

2. Conveyor: spindle conveyor with pitch 152.4mm

3. Baking Oven: IR oven (80±2 degree), UV oven (800-1200mj/cm2)

4. Automatic deionzing booth used for blow off dust and remove static charge on component

5. Air Handling Unit: 15-18.5 KW suction blower with multiple filter

6. Turnkey project of fixed-gun automatic painting plant;

7. Pollution Control: fume control unit is fixed with this automatic painting plant

8. Capacity: this automatic painting plant is suitable for mass production and 24 hours running

9. All air supply or exhaust of this automatic painting plant is controlled with VFD.