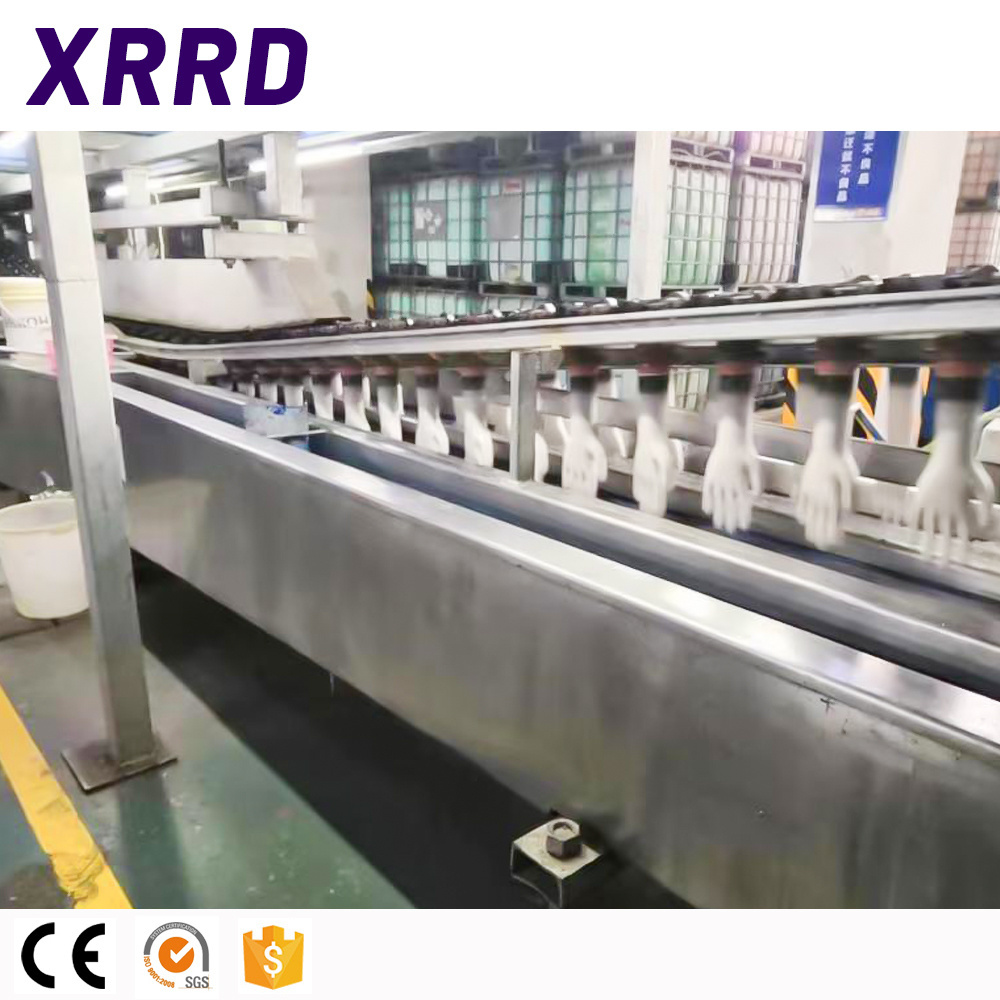

Hand mold cleaning→Hand mold oven→coagulate tank→oven→Latex dipping tank1→Oven→Latex dipping tank 2→Oven→water washing→Oven→Beading→Main oven→Cooling→Chlorine wash tank→water washing→neutralization→PU tank→Final oven→Prestripping→stripping→QC→Packing→Storing→Pre-selling check→Sold.

3. Huge returns can be made by buying glove machine

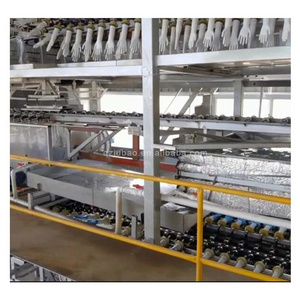

At present, the disposable glove production line, especially the one-time glove manufacturing equipment cost is higher. At the same time, the production of disposable gloves requires advanced support equipment and technical support. More and more automation. As a result, the nitrile glove manufacturing equipment is relatively large. New entrants must have the strong financial strength and technical equipment to compete with existing enterprises.

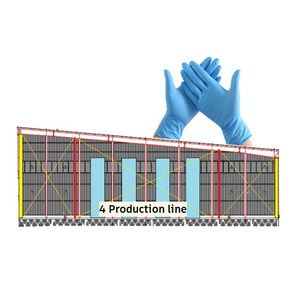

The Nitrile gloves machine is based on the chemical properties of raw materials and glove molding process design requirements, process compact, well-structured. However, there are significant scale effects in the nitrile glove industry. That is, unit costs continue to fall as output increases. In recent years, with the upgrade of a nitrile glove manufacturing machine and the continuous application of automation equipment. Entry into the disposable glove industry. Especially in the field of high-end nitrile gloves, continued to grow. As a result, competitors are relatively few.

XRRD nitrile gloves machine is based on the chemical properties of raw materials and glove molding process design requirements, process compact, well-structured.

Often, the nitrile glove line is a business opportunity that can recoup investment and make money in a short period of time. Contact us now to learn more about nitrile glove manufacturing equipment

We also provide: PVC Gloves Production Line, Latex Gloves Production Line, Household Gloves Production Line.