- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

50 mm

-

Max. Table Load(kg):

-

400

-

Travel (W-axis) (mm):

-

50 mm

-

Range of Spindle Speed(r.p.m):

-

100 r.p.m

-

Spindle Motor Power(kW):

-

1.25

-

Production Capacity:

-

500 Sets per Month

-

Place of Origin:

-

China

-

Brand Name:

-

XDEM

-

Voltage:

-

110/220V

-

Dimension(L*W*H):

-

1

-

Weight (T):

-

0.1 T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Driving type:

-

DC Motor

-

Boring scope:

-

38-400mm

-

Bar size:

-

35/50mm

-

Power:

-

1250W

-

Cutter material:

-

alloy cutter, white blades

-

mounting options:

-

Single Arm,Double Arm,Center

-

boring stroke:

-

280mm

-

Certification:

-

ISO9001:2008 CE

Quick Details

-

Table Size (mm):

-

1300x1600

-

Table Travel (X) (mm):

-

1000 mm

-

Table Travel (Y) (mm):

-

50 mm

-

Table Travel (Z) (mm):

-

50 mm

-

Max. Table Load(kg):

-

400

-

Travel (W-axis) (mm):

-

50 mm

-

Range of Spindle Speed(r.p.m):

-

100 r.p.m

-

Spindle Motor Power(kW):

-

1.25

-

Production Capacity:

-

500 Sets per Month

-

Place of Origin:

-

China

-

Brand Name:

-

XDEM

-

Voltage:

-

110/220V

-

Dimension(L*W*H):

-

1

-

Weight (T):

-

0.1 T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Driving type:

-

DC Motor

-

Boring scope:

-

38-400mm

-

Bar size:

-

35/50mm

-

Power:

-

1250W

-

Cutter material:

-

alloy cutter, white blades

-

mounting options:

-

Single Arm,Double Arm,Center

-

boring stroke:

-

280mm

-

Certification:

-

ISO9001:2008 CE

XDTH50 Portable Hole Boring and Welding Machine

Product Description

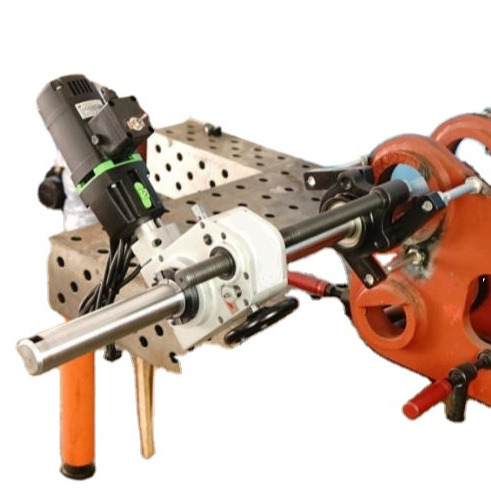

♦ The XDTH series boring machine line bore welder is the latest product of XDEM, it is the combination of sophisticated industrial design and on-site boring. The most advanced technology, can realize the field boring, safe, accurate and efficient.

♦

Powerful processing capability. It can processing and repair the shaft pin hole, hinge hole,

steam turbine wheelsets connecting hole, pump, valve, pipe internal hole ect. It also can

complete end face processing, external circle surfacing, to meet the concentric boring and

welding precision machining requirements

♦

Patented drive head system. Innovation to make rotate, feeding two systems together, the

motor all use the international famous brand as the driving, offer strong, stable torque

output. Light in weight, The boring feed speed stepless regulation within the range of

0-0.5mm, A gently pat, can achieve positive and reverse rotation, practical.

♦

High strength boring bar – the bar use the 40Cr/42CrMo material, the overall conditioning,

quenching, surface plating, high strength, guaranteed the cutting and the accuracy

♦ A dvanced internal and external circular patch welding system, Muti use in one machie, high efficiency.

♦

All accessories and parts design and manufacture atthe purpose of exquisite, durable and

maximum security.

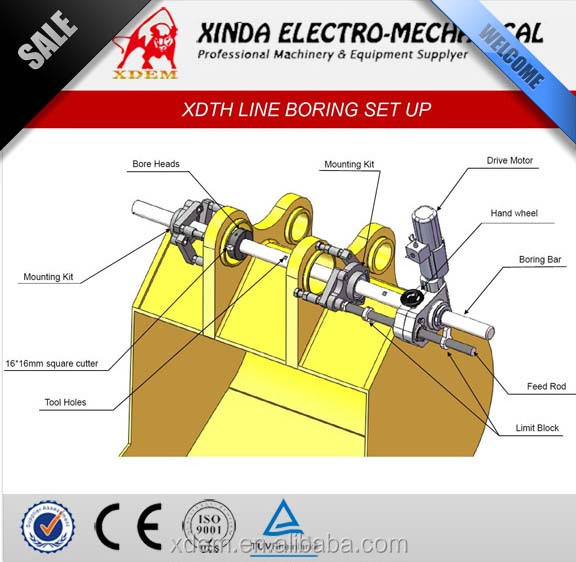

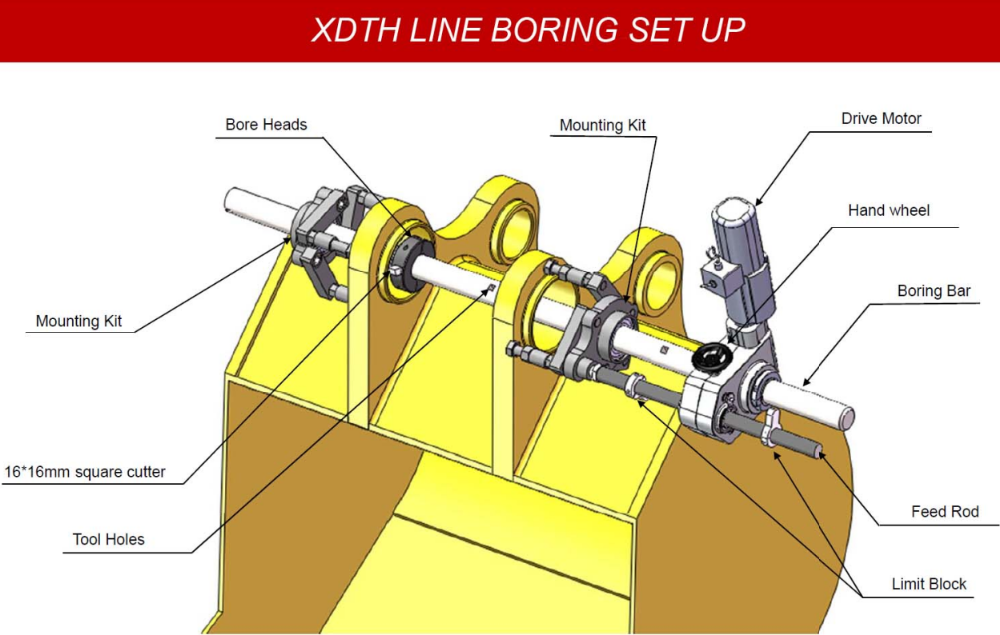

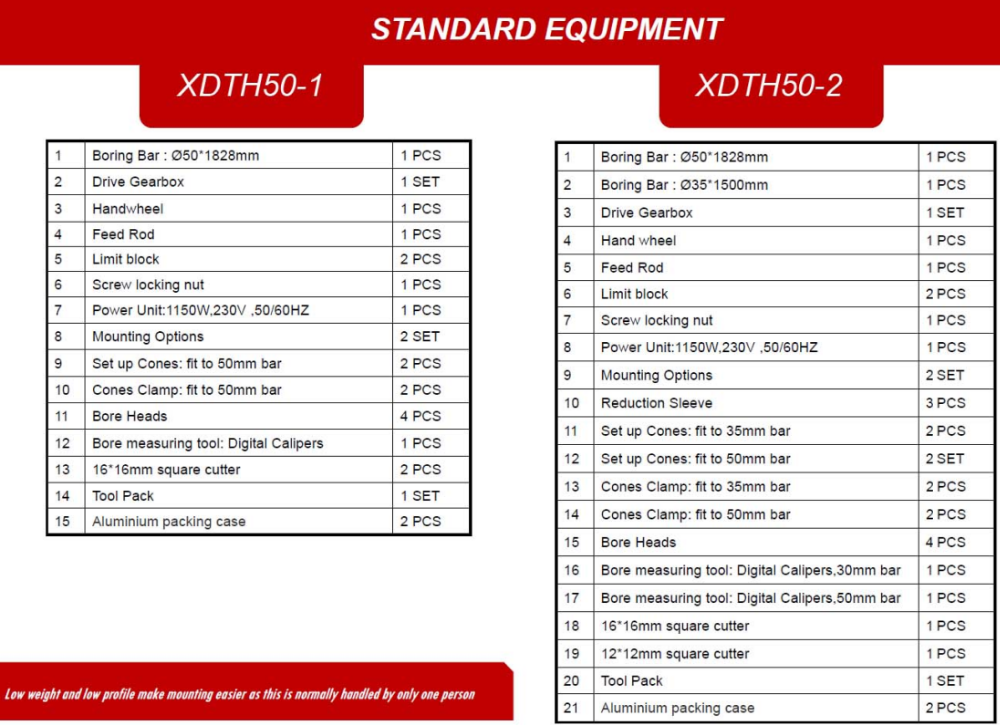

Line Boring Machine Technical P arameter s

|

Model |

XDTH50-1 |

XDTH50-2 |

XDTH60-1 |

XDTH-60-2 |

|

|

Boring diameter (mm) |

55~ 40 0 |

38~ 400 |

65~ 5 00 |

35~ 600 |

|

|

B ar size (mm) |

φ50*1828 |

φ35*1200 |

φ60*2000 |

φ60*3000 |

|

|

φ50*1828 |

φ30*1200 |

||||

|

Driver type |

DC MOTOR |

Hydraulic |

|||

|

Power(w) |

1250 |

1250 |

1800 |

1800 |

|

|

Rotating Speed |

0~ 150rpm |

0~ 150rpm |

0~ 1500rpm |

0~ 150rpm |

|

|

Surface Roughness |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

|

|

Roundness |

≤0.05mm |

≤0.05mm |

≤0.05mm |

≤0.05mm |

|

|

Boring Length (mm) |

300 |

228 |

400~1000 |

400~1000 |

|

|

Feed(mm/r) |

0~0.5 |

0~0.5 |

0~0.5 |

0~0.5 |

|

1. The voltage can be custom according to the customer requests.

2. The boring size also can custom according to theneeds.

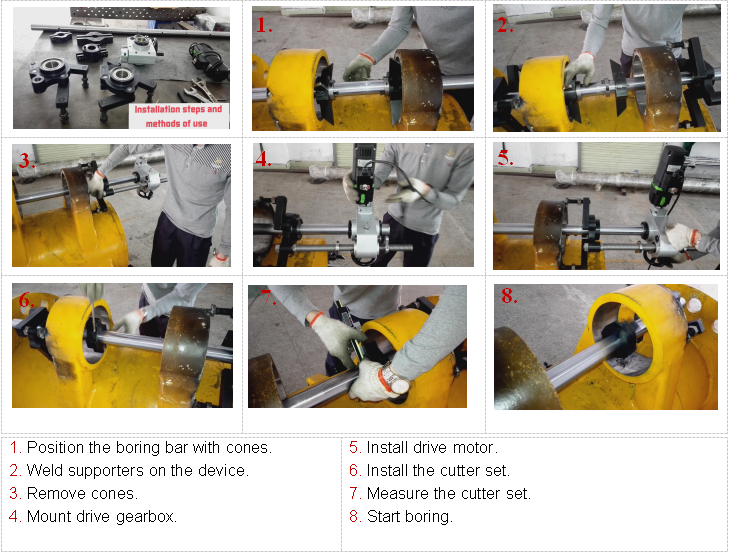

Installation Steps and Method of Use