- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5250*1780*2200mm

-

Year:

-

2020

-

Power (kW):

-

180 kW

-

Weight (KG):

-

8500 KG

-

Name:

-

Waste Tire Recycling Machine

-

Raw material:

-

Used Tire

-

Application:

-

Waste Tire Processing Machinery

-

Function:

-

Recycling Tire

-

Key word:

-

Tyre Recycling Machine China

-

Advantage:

-

Service-life Longer

-

Capacity:

-

10tons

-

Color:

-

Blue Green

-

Motor:

-

Famous Brand

-

Structure:

-

Double Shaft Blade

-

Certification:

-

CE/ISO/TUV

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LUODATE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

5250*1780*2200mm

-

Year:

-

2020

-

Power (kW):

-

180 kW

-

Weight (KG):

-

8500 KG

-

Name:

-

Waste Tire Recycling Machine

-

Raw material:

-

Used Tire

-

Application:

-

Waste Tire Processing Machinery

-

Function:

-

Recycling Tire

-

Key word:

-

Tyre Recycling Machine China

-

Advantage:

-

Service-life Longer

-

Capacity:

-

10tons

-

Color:

-

Blue Green

-

Motor:

-

Famous Brand

-

Structure:

-

Double Shaft Blade

-

Certification:

-

CE/ISO/TUV

Popular Waste Tire Recycling Plants / Tire Recycling Rubber Powder Production Line

Products Description

Features:

1.

Us

e

thick a

nd

he

avy

duty knives,

high shredding efficiency

.

3. Bearing adopts the open type, easy to replace blade.

4. Full automatic

24 hours continuous running

plant with water cooling system, small space; Low energy consumption; No polluted water; No waste gas; No waste residue; high efficiency.

5. Configuration

adjustable

according to different requirements.

Full A

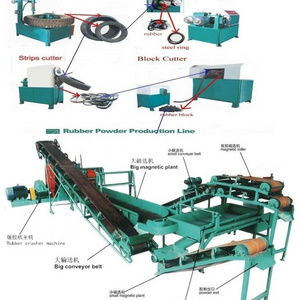

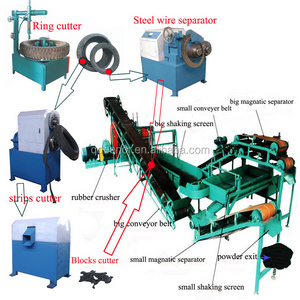

utomatic Waste Tire Recycling Production Line Process:

Whole Tir

e Recycling Process

:

1.

Separate steel in sidewall (clean steel for direct selling).

2. Entire tires shred to

5 cm rubber pieces

, through firstly steel wire separation system.

3. 5 cm rubber pieces crushed into small rubber crumbs, through second steel wire separation get

98% pure steel wire

. (Steel wire cleaning plant available for higher request on steel wire purity).

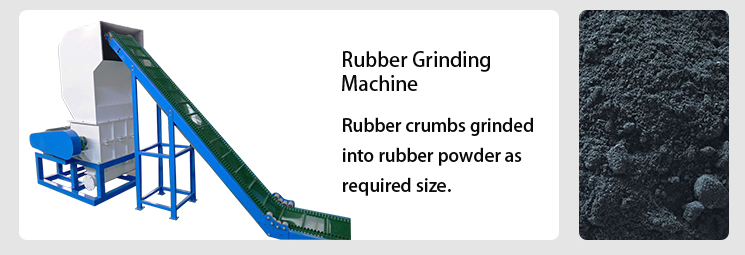

4. Rubber crumbs grind into rubber powder

as required size

.

5. Fiber separated.

Parameters

|

Model

|

Blades Size (mm)

|

Blades (pcs)

|

Reducer (sets)

|

Motor Power (kw)

|

Main Shaft Speed (r/min)

|

Dimensions (mm)

|

|

LDT600

|

Φ250*10

|

48

|

400*2

|

15*2

|

18-25

|

1450*870*2200

|

|

LDT800

|

Φ250*20

|

32

|

400*2

|

30*2

|

18-25

|

2150*870*2200

|

|

LDT1000

|

Φ350*30

|

28

|

650*2

|

37*2

|

18-25

|

3400*1250*2200

|

|

LDT1200

|

Φ350*30

|

38

|

650*2

|

55*2

|

18-25

|

4150*1250*2200

|

|

LDT1500

|

Φ400*40

|

36

|

750*2

|

75*2

|

18-25

|

4150*1250*2200

|

|

LDT2000

|

Φ530*50

|

38

|

850*2

|

90*2

|

18-25

|

5250*1780*2200

|

|

LDT2500

|

Φ600*60

|

60

|

1000*2

|

110*2

|

18-25

|

7500*3200*3800

|

|

LDT3000

|

Φ600*75

|

56

|

1200*2

|

132*2

|

18-25

|

8600*3500*4000

|

Our Advantages

Final Products

Application & Case

Application

5-10 Mesh:

Track, school playground, bowling alley, sidewalk, composite rubber floor

10-20 Mesh:

rubber floor tile, plastic runway, lawn quartz sand, cottonseed pellet meal, aircraft court, gym mat, all kinds of court mat

30 Mesh:

insulating rubber, waterproof material, shockproof, gasket, waterproof rolling material, modified asphalt additive reclaimed rubber

Cases

3. Tire Recycling Production Line for Germany Client

Certifications & Customer Visiting

Customer Visiting

Packaging & Shipping

♠ For the loose cargo the machine will be packed by wooden box .

♠ For the full container loading the machine will be packed by wooden pallet and film scraping.

♠ Small machine, we support TNT, DHL, Fedex, UPS.

♠ Big machine, we support delivery by ship.

♠ About the packing can as the client's requirement.

Our Factory

Our Services:

1.

24 hours online service.

-The investigation will be answered within 2 hours.

2.

Track service

, provided to the delivery note.

3.

Free training operation, commissioning and routine maintenance.

4. We can provide professional guidance to install.

-Two year warranty,

full after-sales service.

-Provide customers with custom designs and flowcharts.

5. Independent R & D team and strict scientific managem

ent system.

FAQ

information we need to know:

1. What is the size of your old tires?

2. What capacity (kg/h) do you want?

3. Final products size(mm)?

4. When will you want the machine? (Times for delivery)

You may ask:

1. Are you manufacturer or trading company?

We are manufacturer with 26 years experience on machines.

2. How do you assistant to install the machine on worksite?

We are experienced on turn-key project, engineer and technicians will assistant client on

construction, installation, commissioning.

3.What kind of solution you can offer to make sure your shredder can do our job?

1)We will help you confirm the model of our machine.

2)We can design the blade to per your requirements, after you are sure that is good, then we can confirm the order finally.

3)You can visit us to check how to shred before you start the order.

4. Can I use mark machine with different logo and color?

Yes, our machine can be customized to your needs.

Yes, our machine can be customized to your needs.

5. What will we do if we have problems in machine working after we buy the machine?

Luodate has people special for after-sale service, if customers outside China have problems when machine working, just feel free to send us the picture or video to show us, we will give you solutions in 24hours.

Hot Searches