- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Type:

-

Pipe Production Line

-

Pipe Material:

-

PVC, PP, PE

-

Voltage:

-

380V 3Phase 50HZ or customized

-

Weight:

-

3-5T

-

Certification:

-

CE, ISO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Output Capacity:

-

80-100 kg/ hr

-

Motor:

-

SIEMENS

-

Contactor:

-

SCHNEIDER

-

Inverter:

-

ABB

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

300 rpm

-

Place of Origin:

-

China

-

Type:

-

Pipe Production Line

-

Pipe Material:

-

PVC, PP, PE

-

Voltage:

-

380V 3Phase 50HZ or customized

-

Weight:

-

3-5T

-

Certification:

-

CE, ISO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Output Capacity:

-

80-100 kg/ hr

-

Motor:

-

SIEMENS

-

Contactor:

-

SCHNEIDER

-

Inverter:

-

ABB

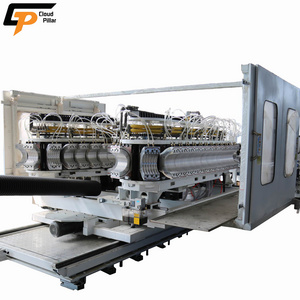

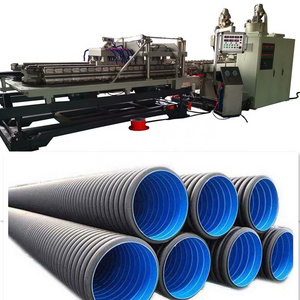

PP PE PVC Corrugated pipe making machine

The production line is mainly used to produce small diameter single wall PVC,PP and PE corrugation pipe, which could be used as wire and cable passing pipe ,washing machine drain pipe, dust collector pipe; Small size corrugation pipe of 4.5-50mm could be made for car use purpose. Being composed of 65/45/30 extruder, corrugated pipe mould forming machine, pipe die, air-cooling device, winder, the production line can extrude and mold PVC, LDPE, HDPE and other thermoplastic corrugated pipe of many specifications continuously.

| Pipe diameter | 8-32mm | 16-75mm |

| Main Extruder model | SJ50 | SJ65 |

| Main Extruder L/D | 25:1/28:1/30:1 | 25:1/28:1/30:1 |

| Capacity | 30-50kg/h | 60-80kg/h |

| Main Motor | 11KW/15KW | 18.5KW/22KW |

| Cooling type | Air fans cooling | Air fans cooling |

| Forming mould quantity | 50 paris | 60 pairs |

| Production Speed | 8-12m/min | 8-15m/min |

| Forming machine motor | 1.5kw | 1.5kw |

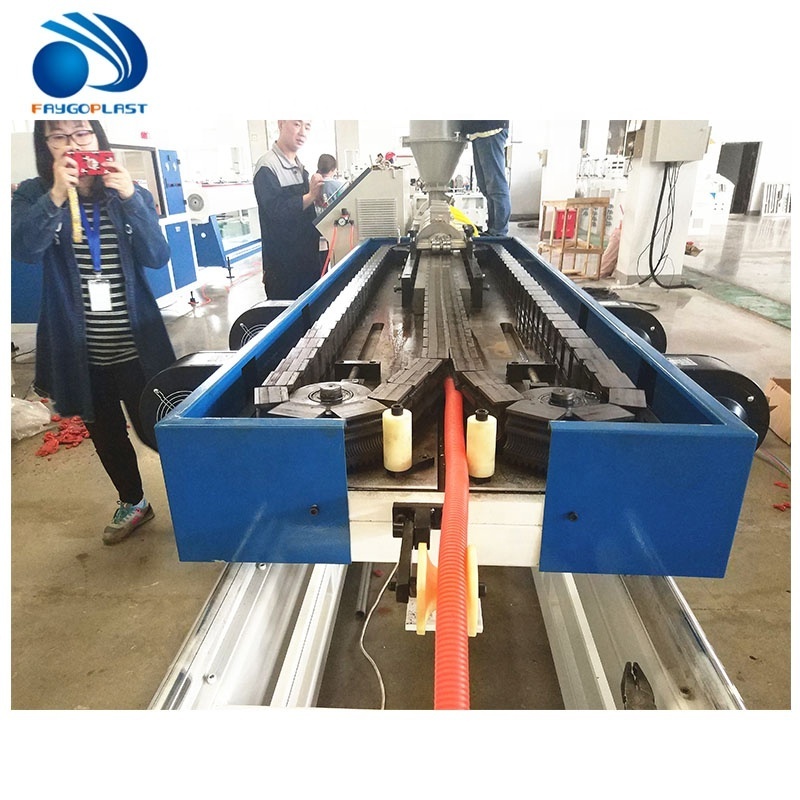

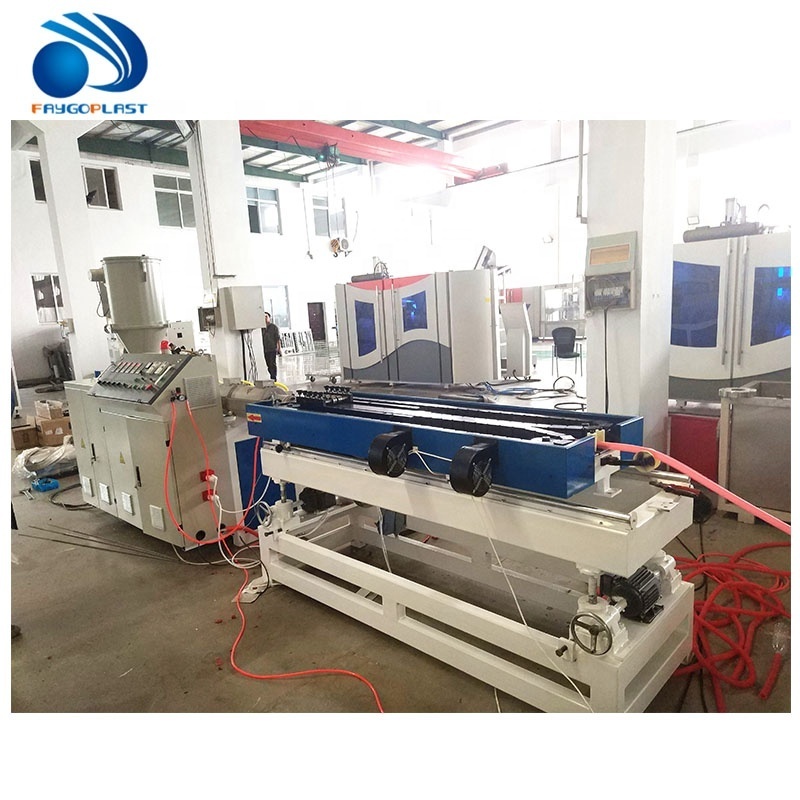

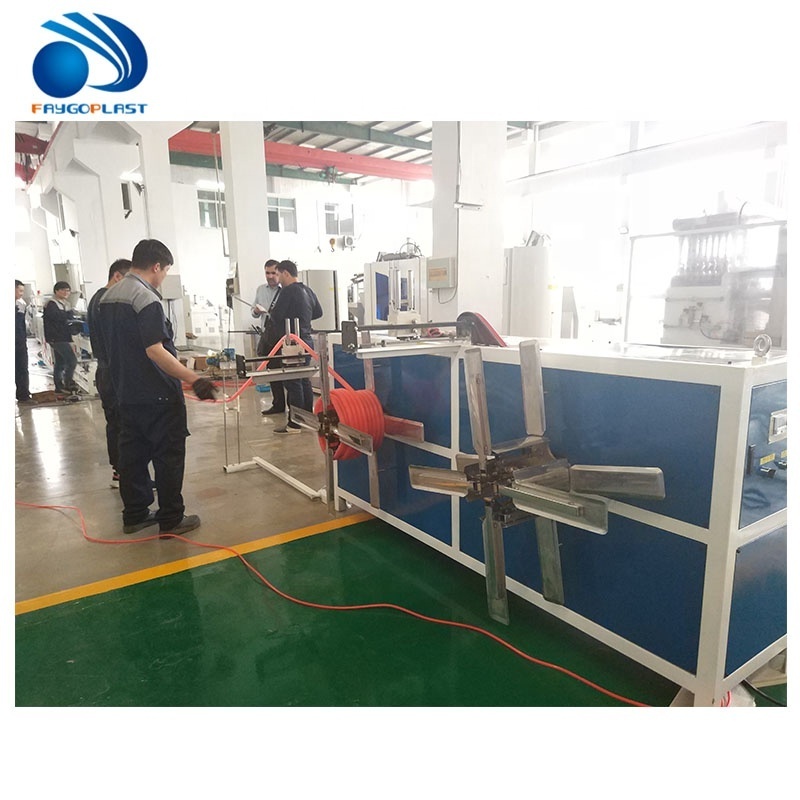

Machine Show:

38GrMoALA alloy steel under nitriding treatment . Depth of screw:0.4-0.6mm hardness: HV>740. Depth of barrel:0.5—0.7mm hardness: HV>940

Extrusion capacity: 60kg/h, Main Electrical Parts: Temperature Controller: OMRON, Contactor: SIEMENS

Plastic Corrugated Pipe Molding Machine, Machine Size:2300*650*1150mm, Motor Power:3-4kw, Pipe Diameter:10-58mm

production Speed:5-22m/min, Number of Mould:46-72pairs,

Mold size:36*56.5*75mm, Length of Molds:4070mm, Cooling mode:water cool, Control Mode:Touch screen.

Feature:Adopted with infrared sensor synchronization, and controlled by PLC, this equipment is drived by servo motor with an advantages

in easy to operate, winding smooth and high benefits.

Company Show:

Jiangsu Faygo Union Machinery Co., Ltd is a new high-tech enterprise covering 2000m2, which specialized in researching and manufacturing blowing machines.

Our product have been exported to Middle East, Southeast Asia, South America and Europe etc. We have received universal confirmation and trust from our customers.

Add: No.8, Feixiang Road, Korea Industry Zone, Fenghuang Town, Zhangjiagang City, Jiangsu Province, China.

Shipping Details:

Clients Show: