- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Item name:

-

Extrusion Machine

-

Raw material:

-

PP PE PVC Granules Powder

-

Motor:

-

SIEMENS Brand

-

Cooling way:

-

Recycling Water Cooling

-

Feature:

-

Competitive Price/Nice service

-

PLC:

-

Siemens

-

Inverter brand:

-

ABB or Delta Brand

-

Related machine:

-

High speed single wall corrugated pipe machine

-

After-sales Service Provided:

-

YES

-

Key words:

-

Single wall corrugated pipe Extrusion Machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

50

-

Weight:

-

2000 KG

-

Item name:

-

Extrusion Machine

-

Raw material:

-

PP PE PVC Granules Powder

-

Motor:

-

SIEMENS Brand

-

Cooling way:

-

Recycling Water Cooling

-

Feature:

-

Competitive Price/Nice service

-

PLC:

-

Siemens

-

Inverter brand:

-

ABB or Delta Brand

-

Related machine:

-

High speed single wall corrugated pipe machine

-

After-sales Service Provided:

-

YES

-

Key words:

-

Single wall corrugated pipe Extrusion Machine

|

Name

|

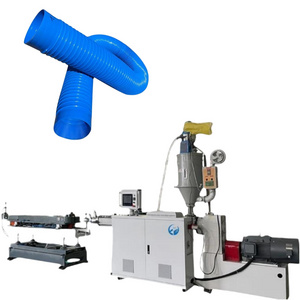

Plastic Pe Pp Pa Pvc Plastic Flexible Single Wall Corrugated Conduit Pvc Pipe Hose Tuba Extrusion Making Machine Production Line

|

|

|

|

||||

|

Related machine

|

High speed single wall Corrugated pipe Machine

|

|

|

|

||||

|

Processing Type

|

Extruding Machine

|

|

|

|

||||

|

Final products

|

1.Air conditioning pipe

2.Shisha hookah hose pipe

3.medical breathing corrugated pipe

4.Washing machine water drainage pipe

5.Electrical wire conduit corrugated pipe

6.Shrinking corrugated pop tube

|

|

|

|

||||

|

Fullwin plastic single-wall corrugated pipe production line developed by our company adopts gears to run moulds and templates so as to realize water circulating cooling air of the products,which ensures high-speed molding,even corrugation,smooth inner and outer pipe wall.These corrugated pipes are especially used as wires of up-market cars,cable protection pipe,water smoking pipe and so on.

Production speed :20-30m/min . |

|

|

|

|

||||

Equipment List

|

NO

|

Name

|

Qty

|

|

1

|

SJ65/30 Single Screw Extruder with vacuum feeder and hopper dryer

|

1set

|

|

2

|

New Design corrugated pipe Die head

|

1set

|

|

3

|

Core bar and mouth mold

|

1set

|

|

4

|

Corrugated pipe forming machine and forming moud

|

1set

|

|

5

|

Double station winding machine

|

1set

|

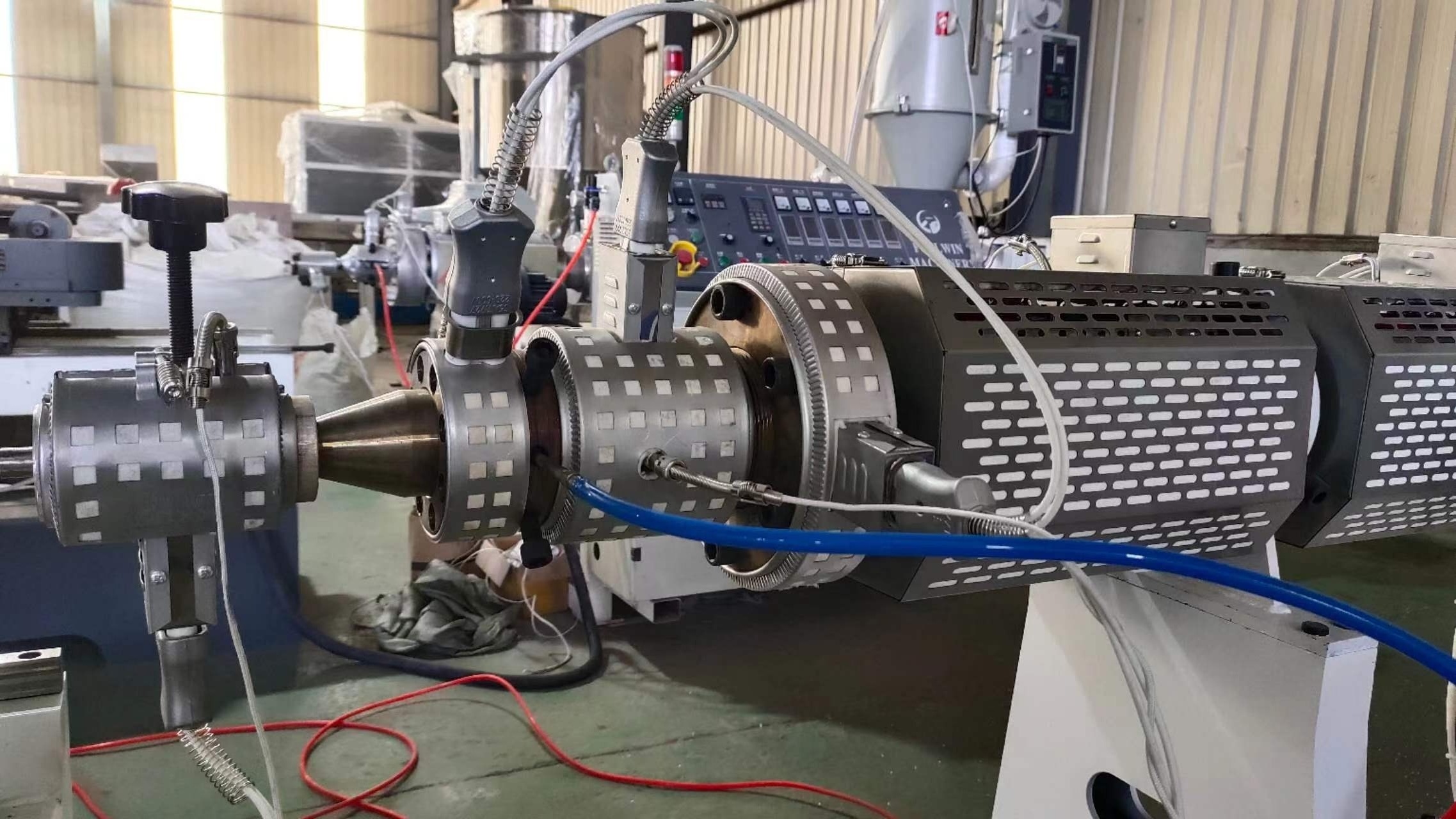

No.1 SJ65/30 Single screw extruder with vacuum feeder and hopper dryer

1.Higher fusion rate, even melting, and stable continuous production. The high efficiency gear motor provides greater torque, longer service and lower noise.

2. For PVC powder raw material market widely use double screw extruder. But FULLWIN design single screw barrel suitable for PVC powder material,PVC granule material and PP PE EVA granule.Use one machine can cover all these materials.it can help customer save the machine cost.

3.Customer can choose PLC control system and Manual control panel according to their usage habits.

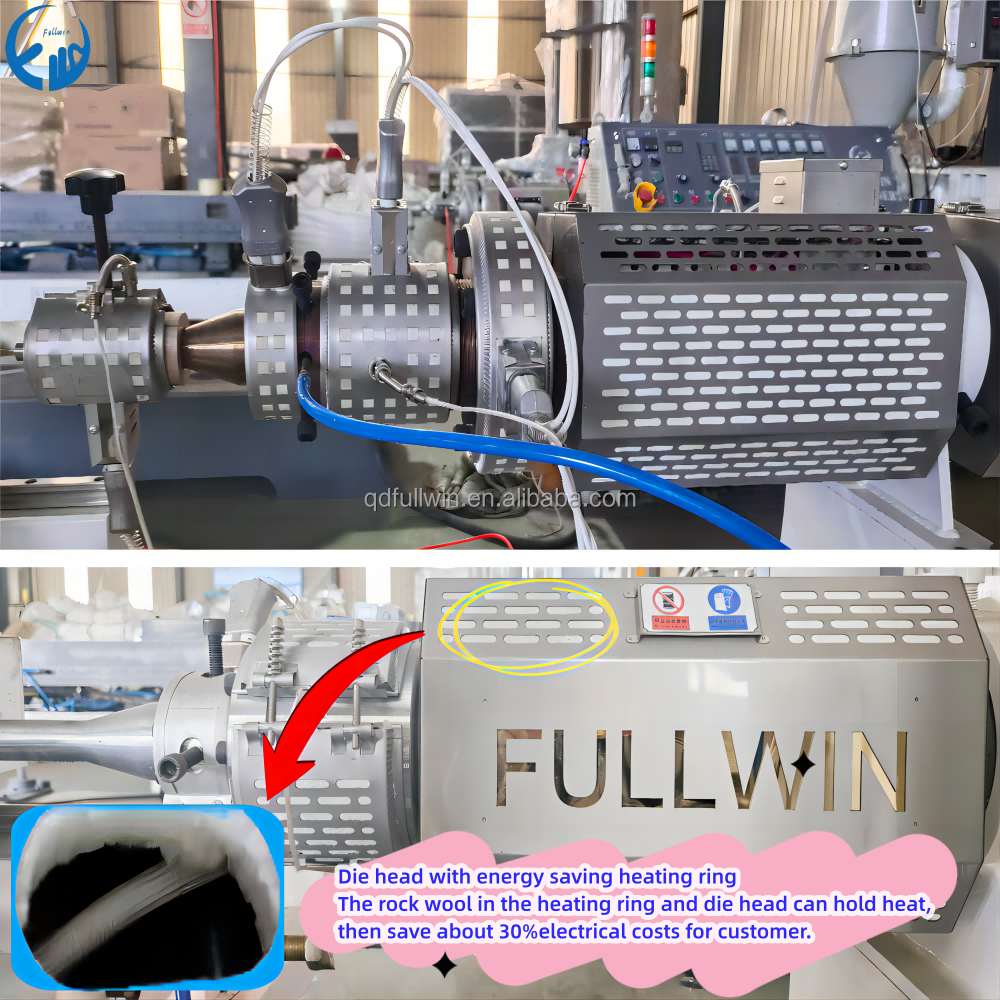

No.2 New Design corrugated pipe Die head

1. Head quality: According to customer's requirement.

2. Adding rock wool with 20mm into the heater ring can help keep heat, then

saving 30% of electricity

for customer.

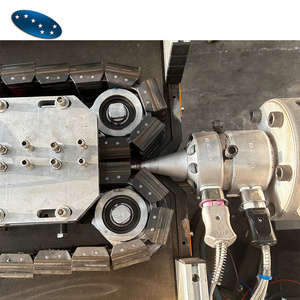

No.3 Core bar and mouth mold

Fullwin new design, the core bar and mouth mould fit together. When changing the size, it don't need change the core bar and mouth separately like old design. It can save more than 1 hour and half when cleaning the waste material.

No.4 Corrugated pipe forming machine and forming moud

1.Forming machine adjustment:manual control left and right, Electric control up and down.

2.Water cooling system, cooling easier.

3. Double cavity in one set of mould. When change the size,just up and down forming machine,no need put out all set mould. it can save more long time for customer.

2.Water cooling system, cooling easier.

3. Double cavity in one set of mould. When change the size,just up and down forming machine,no need put out all set mould. it can save more long time for customer.

No.5 Double station winding machine

Automatic wiring device which can balance the speed between pipe producing and rewinding.The device will stop rewinding when the pipe production is slow to prevent the pipe from getting too tight or disconnected.

Final Product & Application

You just tell us which machine you want,we will do the rest work:

1. Design and produce the most suitable machine for you.

2. Before delivery, we will test the machine until you are completely satisfied. (Welcome to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service :

(1) Field installation and commissioning;

(2) Field training your workers;

3. Delivery.

4. We will provide after-sales service :

(1) Field installation and commissioning;

(2) Field training your workers;

(3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

(4) Free Spare Parts ;

(5) Video/Online technical support.

customer feedback

Packing and delivery

Company Photos

Exhibition

FAQ

1.Are you machinery factory or trading company?

We are machinery factory

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.Why should you buy from us not from other suppliers?

Advanced production technology with design capability; Reasonable price with good quality and best delivery time; Our sales team will give prompt feedback within 24 hours ; Profession after sales service system.

Advanced production technology with design capability; Reasonable price with good quality and best delivery time; Our sales team will give prompt feedback within 24 hours ; Profession after sales service system.

4.Are the

Installation and stuff training available from you?

Yes, our engineers will guide machine installation and train your workers.

Yes, our engineers will guide machine installation and train your workers.

Hot Searches