- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanhai

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

25M*3M*3M

-

Power (kW):

-

90

-

Weight:

-

10000 KG

-

Name:

-

SPC Plastic Profile Extrusion Line

-

Temperature control:

-

Omoron

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB or Delta Brand

-

PLC:

-

Siemens

-

Raw material:

-

PVC Resins+CaCo3

-

Cooling way:

-

Recycling Water Cooling

-

Feature:

-

Competitive price/Long service life/High-accuracy

-

Max output:

-

180kg/h

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanhai

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

25M*3M*3M

-

Power (kW):

-

90

-

Weight:

-

10000 KG

-

Name:

-

SPC Plastic Profile Extrusion Line

-

Temperature control:

-

Omoron

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB or Delta Brand

-

PLC:

-

Siemens

-

Raw material:

-

PVC Resins+CaCo3

-

Cooling way:

-

Recycling Water Cooling

-

Feature:

-

Competitive price/Long service life/High-accuracy

-

Max output:

-

180kg/h

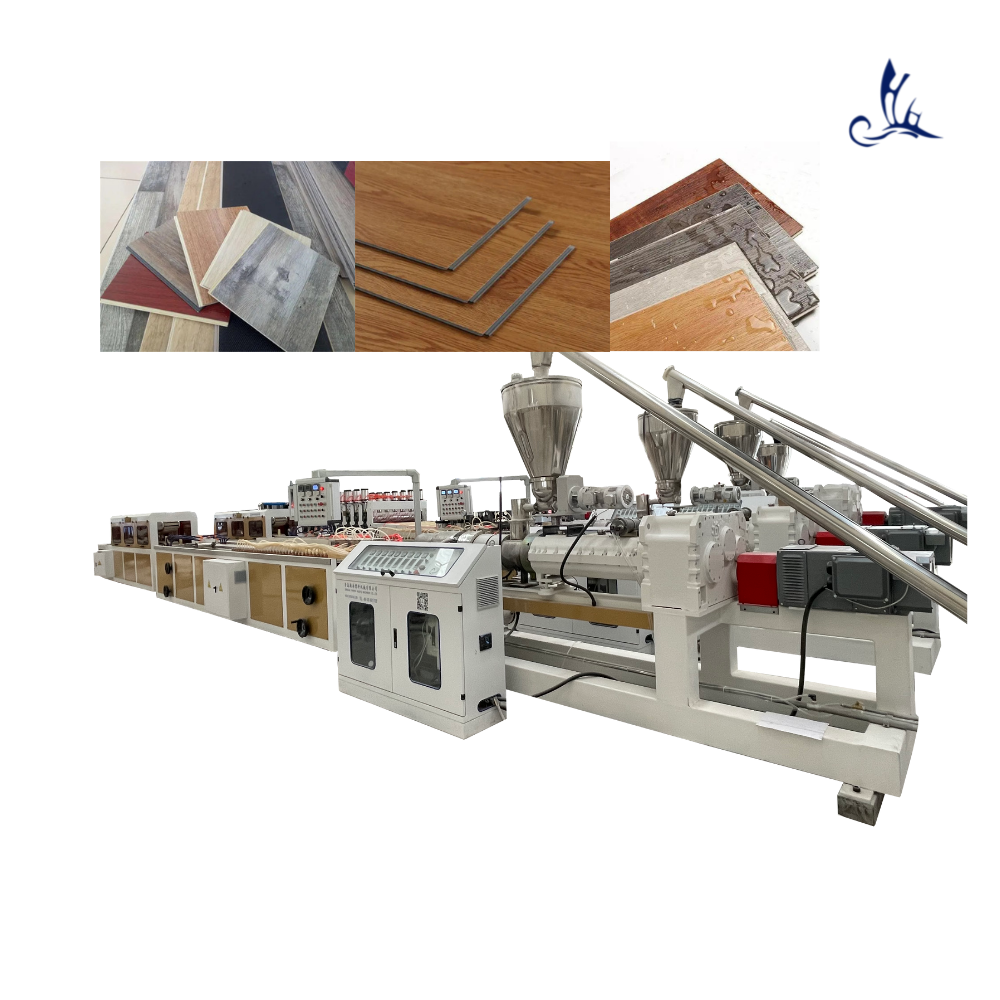

Hot Sale WPC PVC Vinyl Floor Production Line SPC Flooring Tile SPC Lamination Marble Board Making Machine

Product Description

|

NO.

|

Specification

|

Quantity

|

|

1

|

Automatic loading system

|

1set

|

|

2

|

SJSZ80/156 conical double screw extruder

|

1set

|

|

3

|

Mold

|

1set

|

|

4

|

Five roll calender with temperature controller

|

1set

|

|

5

|

Laminating device

|

1set

|

|

6

|

Edge cutting unit

|

1set

|

|

7

|

Hual off machine

|

1set

|

|

8

|

Cutting machine

|

1set

|

|

9

|

Auto stacker

|

1set

|

1.SJSZ80/156 conical double screw extruder with automatic loading system

(1)Big output & L/D ratio screw

(2) Barrel is made of special steel alloy.

(3) Gears are made of steel alloy with heat treatment and are finished with surface precision grinding.

(4)AC motor, selected famous brand products.

(5)Controlled by ABB Inverter.

(3) Gears are made of steel alloy with heat treatment and are finished with surface precision grinding.

(4)AC motor, selected famous brand products.

(5)Controlled by ABB Inverter.

2.Mold

(1)

Coated with chrome & polished

(2) Alloyed mold steel material

(3) Heating rod

(2) Alloyed mold steel material

(3) Heating rod

3.Five roller Calender and side winder with laminating equipemt

(1)

With emergency stop Adjusting method the roller space

(2) neumatic adjusting Temp-regulating of roller

(3) water-heating and cooling Blade method side cutting Electric part with CE certificate Temperature control system

(2) neumatic adjusting Temp-regulating of roller

(3) water-heating and cooling Blade method side cutting Electric part with CE certificate Temperature control system

4.Bracket and Haul-off Machine

(1)A pair of rubber rollers haul off

(2)Speed adjustable control, the up and down rollers are synchronized via drive unit.

(3)With emergency stop

(2)Speed adjustable control, the up and down rollers are synchronized via drive unit.

(3)With emergency stop

5.Cutting machine

(1)With Digital Meters, automatic control cutting length.

(2)Pneumatic system

(3)Push cylinder

(4)Knife

(2)Pneumatic system

(3)Push cylinder

(4)Knife

6. Final product bracket

(1) Material stainless steel

(2) Dimension 2500*1300*1000mm

(2) Dimension 2500*1300*1000mm

SPC Flooring Sheet Making Machine

production line is one of the most advanced sheet production lines with the most advanced technology, the most mature technology, and the most stable equipment in China, which meets the increasingly stringent requirements of the market for plastic sheet.

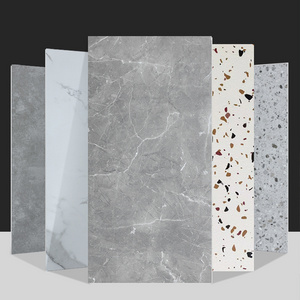

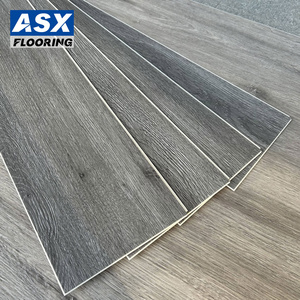

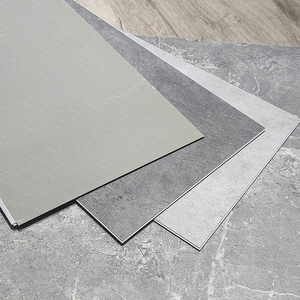

Final Products

Hot Searches