- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500 KG

-

Product name:

-

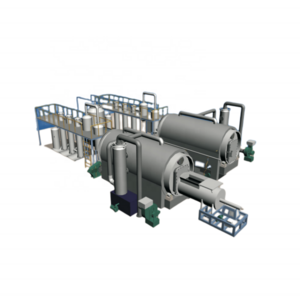

Tire Cracking Furnace

-

raw materials:

-

rubber, waste and scrap of plastics, acrylic, oil sludge, nylon, etc.

-

structural form:

-

Horizontal rotation

-

work pressure:

-

atmospheric

-

Main furnace speed (r/min):

-

0.1 ~0.5

-

Cooling form:

-

water-cooled

-

transmission method:

-

external gearing

-

Heating method:

-

direct heat

-

Noise DB (A):

-

Noise DB (A)

-

Forms of work:

-

intermittent

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuguang

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

500 KG

-

Product name:

-

Tire Cracking Furnace

-

raw materials:

-

rubber, waste and scrap of plastics, acrylic, oil sludge, nylon, etc.

-

structural form:

-

Horizontal rotation

-

work pressure:

-

atmospheric

-

Main furnace speed (r/min):

-

0.1 ~0.5

-

Cooling form:

-

water-cooled

-

transmission method:

-

external gearing

-

Heating method:

-

direct heat

-

Noise DB (A):

-

Noise DB (A)

-

Forms of work:

-

intermittent

This equipment takes waste tyre, waste rubber, waste plastic, acrylic and so on as raw materials, and adopts cracking process for oil refining project. Its main features are: horizontal rotating structure design, so that the equipment is heated evenly, longer service life; special construction of the air outlet to avoid clogging, safer operation; the use of automatic dregs, improve production efficiency; the system operates at atmospheric pressure, to prevent gas leakage, the process is more environmentally friendly; the new countercurrent wet dust removal process, so that the exhaust fumes and dust treatment fully meets the international standards; the whole system process design The whole system has excellent process design and high oil output rate; it can meet the user's cracking process requirements for cracking equipment.

|

sports event |

element |

||

|

structural form |

Horizontal rotation |

||

|

raw materials |

Waste and scrap of rubber, waste and scrap of plastics, acrylic, oil sludge, nylon, etc. |

||

|

Equipment Model |

Model L-500 |

Model L-6000 |

L- 1200 |

|

24h Capacity (T) |

0.5 |

6-7 |

12-13 |

|

24h oil production (T) |

0.2-0.3 |

2.7-3.2 |

5.4-5.8 |

|

work pressure |

atmospheric |

atmospheric |

atmospheric |

|

Main furnace speed (r/min) |

0.1~ 0.5 |

0.1 ~0.5 |

0.1~ 0.5 |

|

Main furnace power configuration (KW) |

2.2 |

4 |

7.5 |

|

Cooling form |

water cooling |

water cooling |

water cooling |

|

Water consumption (T/h) |

0.4 |

4 |

8 |

|

transmission method |

external gearing |

external gearing |

external gearing |

|

Heating method |

direct heat |

direct heat |

direct heat |

|

Installation |

basic |

basic |

basic |

|

Noise DB (A) |

≤85 |

≤85 |

≤85 |

|

Dimensions of the main unit |

Ø1500*3750 |

Ø2000*6600 |

Ø2600*6600 |

|

Forms of work |

intermittent |

intermittent |

intermittent |

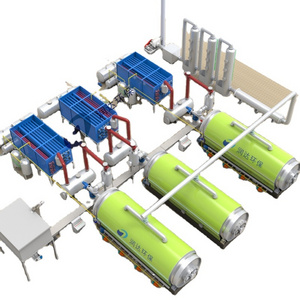

Working Principle:

The raw materials (waste plastics, waste tyres, etc.) are loaded into the oxygen-insulating furnace and heated to produce high-temperature fuel oil gas by cracking, and then produce fuel oil by distillation and condensation, which is a simple process with a high rate of oil production, which can be stabilised at 45% to 60%, and the maximum rate can reach 80%, and the products comply with the relevant national standards.

| End Product | Percentage | Usage |

| Fuel oil | 40-45% | 1. Used as fuel in Industrial such as steel8&iron factories, chemical industrial or hotels and restaurants. 2. For heavy oil generators to get electricity. 3. For distillation to non-standard diesel oil |

| Carbon black | 30-35% |

1. Used for construction bricks;

2. Deep-processed to N330, N660, N774 or color carbon black |

| Steel Wire | 12-15% | Sold or reprocessing |

| Sync gas | 3-5% | Recycling during the operation |

1.Outstanding Features:

a. The reactor need preheat at the first when the machine starts producing.

b. 24h continuous working for 20-30 days without any stops.

c. No need fuels, sync gas is recycled during the operation.

d. Large daily capacity:20-25T/D;25-30T/D

e. New desing of vertical condensers. Good oil quality with high profit.

f. Low requirement on the raw materials.

2. Security:

a: Adopting automatic submerged-arc welding technology

b: All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the

welding shape.

c: Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.

d: Equipped with anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming

system.

3. Environmental-friendly:

a: Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke

b: Smell during operation: Fully enclosed during the operation

c: Water pollution: No pollution at all.

d: Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep-processed or sold directly with its value.