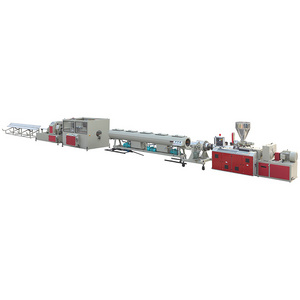

1. Double screws extruder(SJSZ51/105-92/188 )

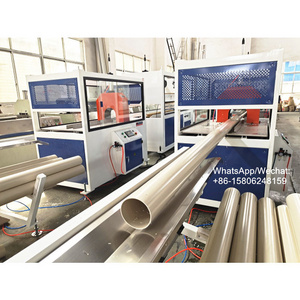

2. Vacuum calibration tank

3. Hauloff machine

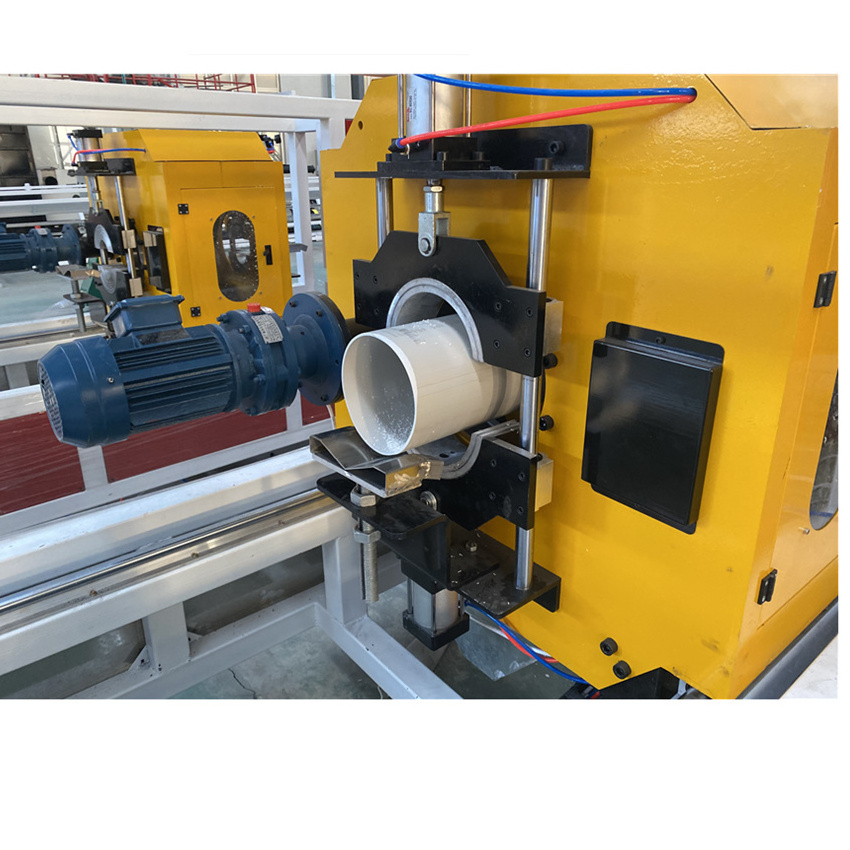

4. Cutting machine

5. Auto stacker

7. Mixer machine , Crusher machine ,Miller machine are also optional from your real needs .

8.

For more information,please contact Whatsapp/Wechat/Telegram/Viber: 008615966899953, Linda Zhang.

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ruijie

-

Voltage:

-

380V,50HZ or Customized

-

Dimension(L*W*H):

-

25m*1.5m-2.5m

-

Power (kW):

-

120

-

Weight:

-

12000 KG

-

Type of extruder:

-

Twin screw

-

Size Calibration Means:

-

Vacuum

-

Hauling Speed(m/min):

-

0.8-12

-

Air compressure:

-

0.6Mpa

-

Water consumption:

-

2CBM

-

Port:

-

Qingdao

-

Term of payment:

-

30%TT,70%TT

-

Keywords:

-

PVC Pipe Extruder Line

-

Machine type:

-

Extrusion Process

-

Final product:

-

CPVC Pipe

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

132:1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ruijie

-

Voltage:

-

380V,50HZ or Customized

-

Dimension(L*W*H):

-

25m*1.5m-2.5m

-

Power (kW):

-

120

-

Weight:

-

12000 KG

-

Type of extruder:

-

Twin screw

-

Size Calibration Means:

-

Vacuum

-

Hauling Speed(m/min):

-

0.8-12

-

Air compressure:

-

0.6Mpa

-

Water consumption:

-

2CBM

-

Port:

-

Qingdao

-

Term of payment:

-

30%TT,70%TT

-

Keywords:

-

PVC Pipe Extruder Line

-

Machine type:

-

Extrusion Process

-

Final product:

-

CPVC Pipe

-

Marketing Type:

-

Ordinary Product

Product Description

Extruder Pvc Tubes Twin Screw CPVC Pipe Extrusion/Pipe Pvc Machine/ Machine Fabrication Tube Pvc

This series of extrusion lines are mainly used to produce PVC drainage pipes and U-PVC,C-PVC water supply pipes.

Advanced design for screws supplies powerful safeguard for the PVC plasticization.

Advanced design for screws supplies powerful safeguard for the PVC plasticization.

Unique inside oil controlling temperature system adapts different technology formulas.

Beautiful and practical stainless steel body for the vacuum calibration and spray cooling system, unique multi-section vacuum system ensures the stable sizing and cooling for pipes; special spray cooling system improves the cooling efficiency ; special water position, water temperature system make the machine more intelligent.

Hauling-off unit adopts particular pedrail structure, which is easy and convenient for operation; pedrail clamping uses

mechanical and pneumatic combining system, which is more reliable.

Cutting system adopts saw blades and planetary cutting means; sumping uses hydraulic system , which ensures the smooth cross-section; equipped with dust-collecting unit, which ensures the clean working environment.

For more information,please contact Whatsapp/Wechat/Telegram/Viber: 008615966899953, Linda Zhang.

|

Model

|

SJSZ51/105-92/188

|

|

Pipe size

|

16mm-630mm

|

|

Material

|

PVC Resin

|

|

Main motor

|

18.5kw-110kw

|

|

Cutter

|

Fixed-length cutting machine

|

|

Stacker

|

4/6 meters length

|

The line components

Extruder Advantages

1. Double screws feeder.

2. ABB/DELTA inverter, Siemens motors, Siemens contactors.

3. PLC control system is optional.

4. High quality gearbox, screws and barrel .

5. Automatic feeder.

3. PLC control system is optional.

4. High quality gearbox, screws and barrel .

5. Automatic feeder.

6.

For more information,please contact Whatsapp/Wechat/Telegram/Viber: 008615966899953, Linda Zhang.

Product usage

Related Products

After Sales Service

Our services

1. We provide factory design.

2. We will check your preparation on electricity, water source , air source, raw material and other preparation job .

3. We will send engieer to your country for machine installation and workders training .

4. We will prepare you excllent formula freely .

5. Technical support is all life long .

6. We offer spare parts with cost .

7. Please send inquiry to us for more information.

3. We will send engieer to your country for machine installation and workders training .

4. We will prepare you excllent formula freely .

5. Technical support is all life long .

6. We offer spare parts with cost .

7. Please send inquiry to us for more information.

Company Details Info

Q: Why do I choose your company?

A: 1) We are one of the leading manufacturers of extruder machinery .

2) Our company has made extruder machine about 14 years with strong experience and advanced technology.

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance.

4) We have Professional technical teams, and will supply 24 hours services.

A: 1) We are one of the leading manufacturers of extruder machinery .

2) Our company has made extruder machine about 14 years with strong experience and advanced technology.

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance.

4) We have Professional technical teams, and will supply 24 hours services.

Q: What should we prepare for Machine ?

A:You should prepare raw material, workshop, water line, electric line, compress air(if you need I can help you buy air

compressor).We would supply workshop layout drawing for you.

A:You should prepare raw material, workshop, water line, electric line, compress air(if you need I can help you buy air

compressor).We would supply workshop layout drawing for you.

Q: Where is your factory located? How can I visit you?

A: Our factory is located in Qingdao city, Shandong province, you can fly to Qingdao AirPort. When you confirm the flight No. and time, please tell me then we will pick you up at Airport.

A: Our factory is located in Qingdao city, Shandong province, you can fly to Qingdao AirPort. When you confirm the flight No. and time, please tell me then we will pick you up at Airport.

Q: If my machine can not work when I receive it, what will your factory do?

A: First of all, do not worry about the thing, we will test the machine before shipment. And if it happened, we will send our

engineer to your factory to repair the machine.

Q: How can I believe your factory and machines.

A: We have CE, ISO certificates. And we have customers all around the world, we can test the machine after it finished for your checking, if it do not reach your demands, we will change, or even give back your deposit.

A: First of all, do not worry about the thing, we will test the machine before shipment. And if it happened, we will send our

engineer to your factory to repair the machine.

Q: How can I believe your factory and machines.

A: We have CE, ISO certificates. And we have customers all around the world, we can test the machine after it finished for your checking, if it do not reach your demands, we will change, or even give back your deposit.

Hot Searches