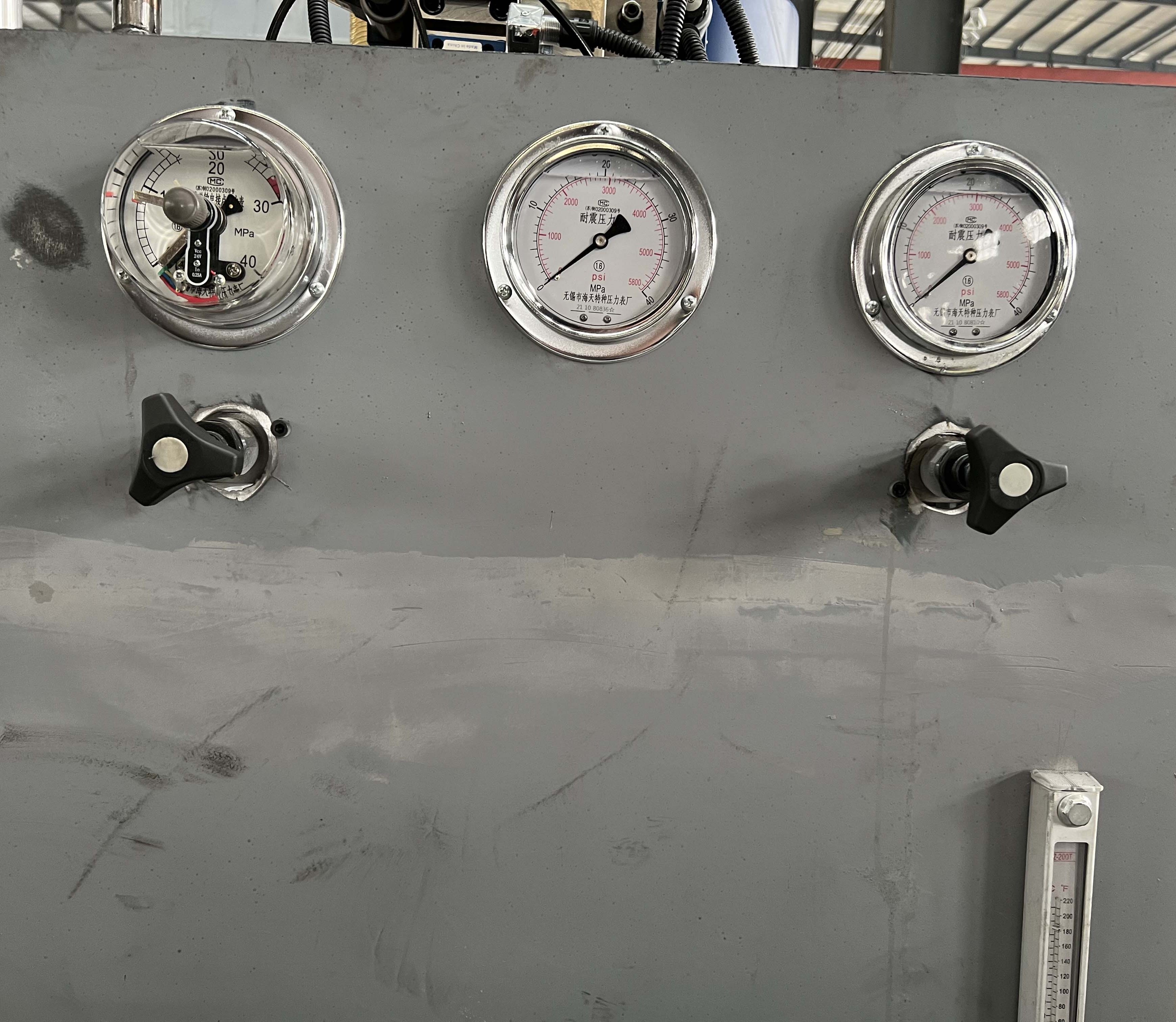

HYDRAULIC STATION

Hydraulic integrated system adopts independent control unit.

Convenient maintenance.

|

Specification

|

|

Unit

|

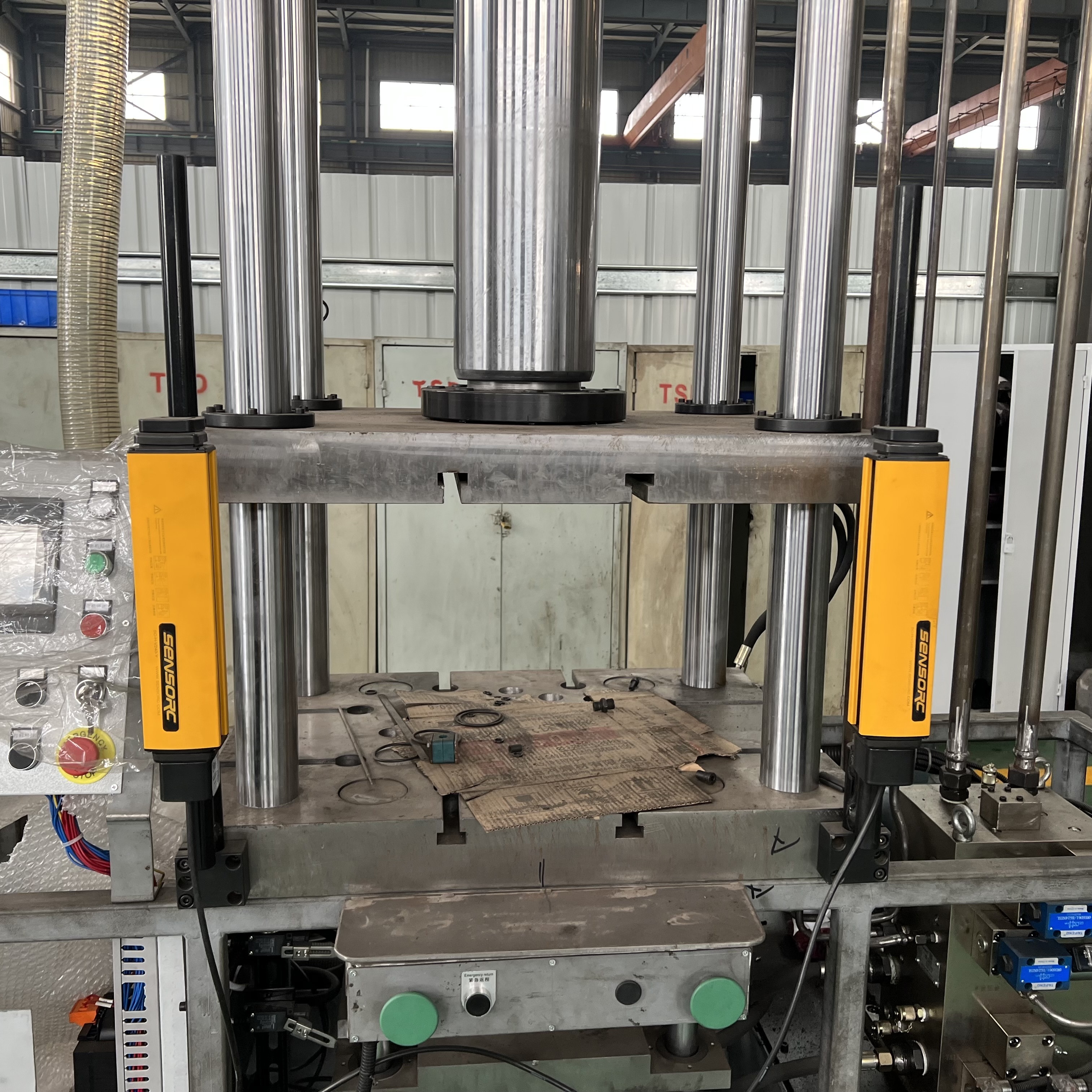

100T

|

100T

|

|

|

Nominal force

|

|

KN

|

1000

|

1000

|

|

|

Ejecting force

|

|

KN

|

20

|

20

|

|

|

Max. pressure of liquid

|

|

MPa

|

25

|

25

|

|

|

Stroke of slider

|

|

mm

|

400

|

500

|

|

|

Max. opening height

|

|

mm

|

700

|

800

|

|

|

Working table size

|

|

mm*mm

|

800x800

|

800x800

|

|

|

Ejecting stroke

|

|

mm

|

200

|

200

|

|

|

Speed of slider

|

Idle speed

|

mm/s

|

54

|

80

|

|

|

|

Working speed

|

mm/s

|

16-24

|

16-24

|

|

|

|

Return speed

|

mm/s

|

46

|

100

|

|

|

Motor power

|

|

KW

|

7.5

|

7.5

|

|

|

Net weight(KG)

|

|

T

|

2..5

|

2.

|

|