- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.25

-

Place of Origin:

-

Water Cooling ( option)

-

Voltage:

-

380V( option)

-

Dimension(L*W*H):

-

1100*700*1200 mm

-

Year:

-

CUSTOM

-

Power (kW):

-

2.2

-

Weight (KG):

-

1000 KG

-

Product name:

-

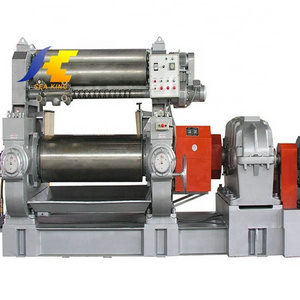

CE ISO Silicone Rubber Mixing Mill/Open mill Rubber Mixer XK-450

-

Roller diameter:

-

450mm

-

Working length:

-

1200mm

-

Front roller line speed m/min:

-

21.8

-

Front and rear roller speed ratio:

-

1/1.27

-

Maximum Roll Distance:

-

12mm

-

One time dosage:

-

About 45-60KG

-

Main motor power:

-

55KW

-

Main motor speed:

-

980r/min

-

Design grid voltage/frequency:

-

380V/50HZ

Quick Details

-

Diameter of Roll(mm):

-

450 mm

-

Rotation Speed of Front Roll(rpm):

-

1 - 19 rpm

-

Length of Roll(mm):

-

1200 mm

-

Roll Ratio(Front/Back):

-

1:1.25

-

Place of Origin:

-

Water Cooling ( option)

-

Voltage:

-

380V( option)

-

Dimension(L*W*H):

-

1100*700*1200 mm

-

Year:

-

CUSTOM

-

Power (kW):

-

2.2

-

Weight (KG):

-

1000 KG

-

Product name:

-

CE ISO Silicone Rubber Mixing Mill/Open mill Rubber Mixer XK-450

-

Roller diameter:

-

450mm

-

Working length:

-

1200mm

-

Front roller line speed m/min:

-

21.8

-

Front and rear roller speed ratio:

-

1/1.27

-

Maximum Roll Distance:

-

12mm

-

One time dosage:

-

About 45-60KG

-

Main motor power:

-

55KW

-

Main motor speed:

-

980r/min

-

Design grid voltage/frequency:

-

380V/50HZ

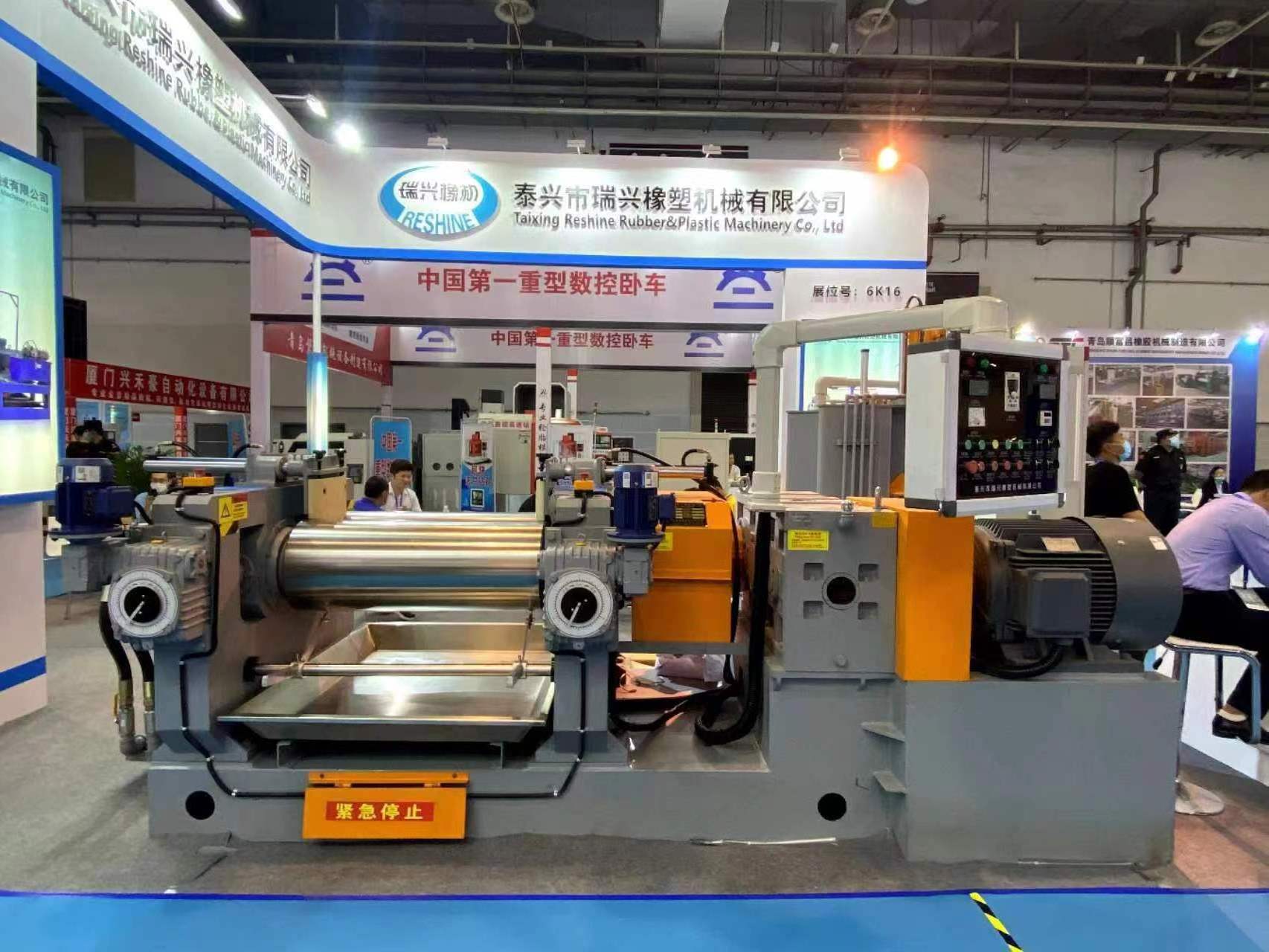

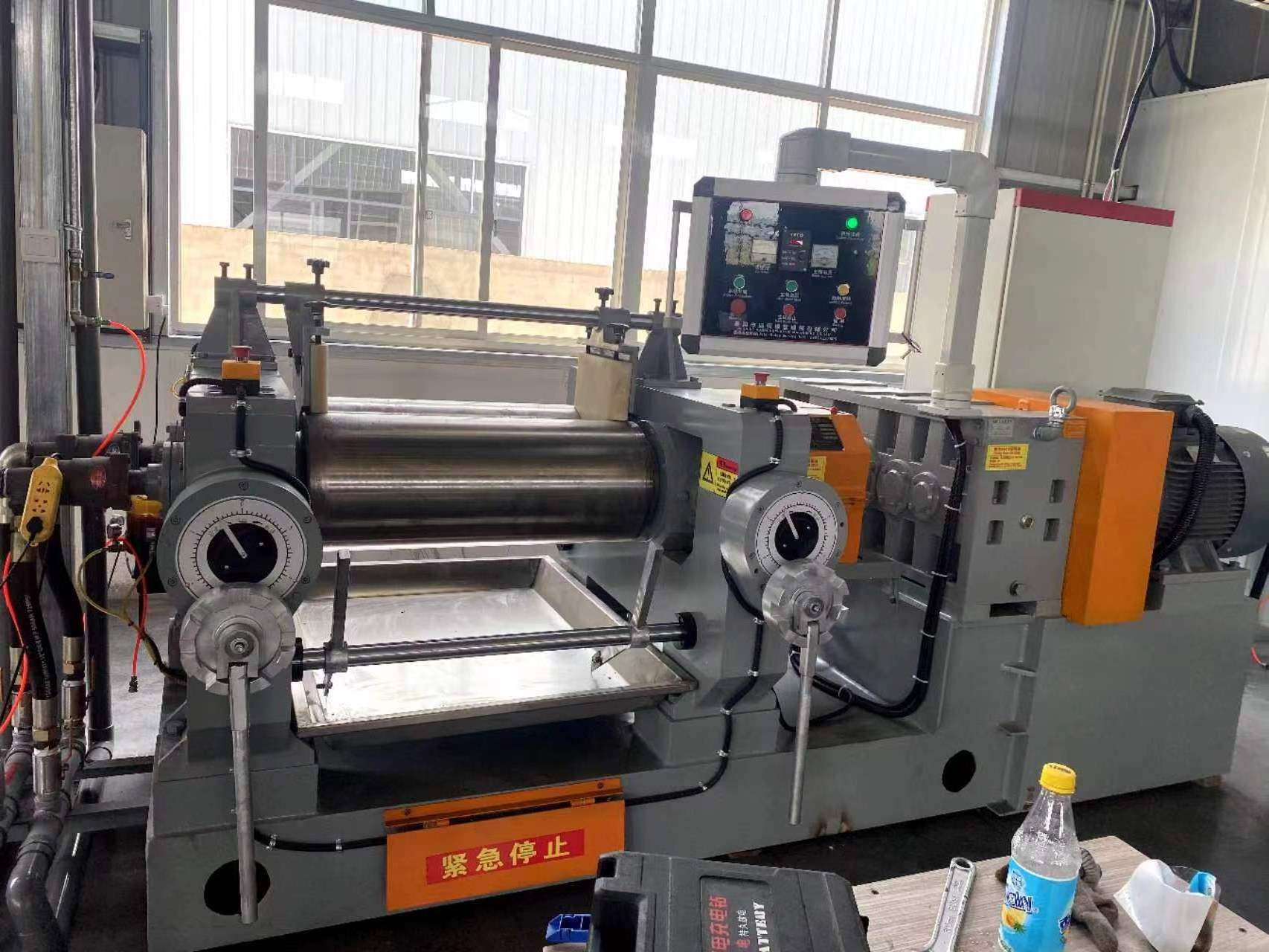

CE ISO Silicone Rubber Mixing Mill/Open mill Rubber Mixer XK-450

Supply of equipment:

1. Equipment name and quantity: ZW-301-450B(18 inch) Advanced Open Type Rubber Refining Machine a set of

2. Main parts: 1. chassis, 2. frame, 3. roller, 4. gear, 5. reducer, 6. motor, 7. hydraulic automatic rubber turning device; 8. main control cabinet;

Technical parameters:

|

Roller diameter |

450mm |

|

Working length |

1200mm |

|

Front roller line speed m/min |

21.8 |

|

Front and rear roller speed ratio |

1/1.27 |

|

Maximum Roll Distance |

12mm |

|

One time dosage |

About 45-60KG |

|

Main motor power |

55KW |

|

Main motor speed |

980r/min |

|

Design grid voltage/frequency |

380V/50HZ |

|

Overall dimensions |

3000 X 1760X1820 mm |

|

W eight |

~10 tons |

Configuration of the opening machine :

|

S peed reducer |

Adopting Shandong Lianfeng ZLY224 hardened gear reducer (domestic famous brand) |

|

E lectrical machinery |

Adopting Shandong Flying Horse motor (domestic famous brand) |

|

R oller |

Adoption of Wuxi Taihu cold hard alloy casting rolls (domestic famous brand) |

|

Bearings |

Adoption of Liaoning Wafangdian Metallurgical Group (Domestic Famous Brand) |

|

Electrical component |

Adopting Astronergy (domestic famous brand)) |

Characteristics of the refining machine:

The structure of the rubber refining machine mainly consists of a one-piece base, frame, front and rear rollers, transmission gears, speed reducer, manual pitch adjustment device, roller temperature adjustment device, safety switch, electrical control system.

The roller material is cold hard alloy casting, with high hardness and wear resistance, roller temperature regulating device, water cooling is used in the roller to regulate the roller temperature to meet the process requirements.

The machine is energy-saving, environmental protection, high efficiency, with bearings instead of nylon tiles, copper bushings, reducer selection ZSY hardened gear reducer, with high transmission efficiency, low noise, long service life and so on. In the use of the thinnest piece of 0.03mm, the bearings are lubricated by electric dry oil pump.

Equipment factory, test run and acceptance:

1. Factory acceptance criteria:

(1) In line with the contract annex "technical agreement" requirements;

(2) T est drive, acceptance, both sides of the organization in the supplier's plant to carry out load test drive, running work.

Delivery period: 30 days.

The main paint color of the equipment: sky blue/medium yellow

Quality assurance and technical services:

(1) The warranty period is 12 months after the site acceptance of the shipment date, during this period the machine itself quality problems by the supplier is responsible for repair, the required use by the supplier.

(2) Quality guarantee period, in the demand side under the correct use of the conditions of failure, by Party B is responsible for providing technical services, due to mismanagement of the demand side, improper maintenance or illegal operation of the damage caused by the demand side, the supply side to provide technical services, the demand side to bear the cost, the supply side in the notification within 2 hours to give a reply.

Dongguan Zhongwei Automation Technology Co., Ltd. was established in 2014, is a professional enterprise specializing in the design, research and development, manufacturing and sales of rubber and plastic machinery and equipment, such as Open Mixing Mil, Intensive kneader, Extruders, Pelletizing Equipment, etc. We have a team of nearly 100 people, and we are constantly improving our production management and expanding our production scale.

We have a very professional R&D team to meet the special requirements of customers and customize the machines for them. Our machines are not only used in rubber and plastic industry, but also by EVA, electrical, ceramic, metal and other industries, sold to more than 100 countries in the United States, Europe, Southeast Asia, South America, and have been praised by our customers and established a long-term and stable cooperative relationship.

1. How to choose the most suitable Mechanical Equipment ?

Our professional team will give you the best suggestion as long as you tell us what kind of produce you need to do andthe required specification.

2. What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

3. Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

5. Do you have customers of our country before?

Now our machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European , India, Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia, Brazil...and so on.

6. How about your warranty?

Generally,our warranty is two years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

7. How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many machines abroad by sea or by air without damage.

8. What is the order process?

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment - packing - delivery - customer receiving - after service.

9. How to install and use the product?

The product is shipped with an operating instructions and video of English version.

How to contact us?

Send your inquiry details in the below, click " Send " Now!

Click here >>>> More Information !!!