- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

30-50kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

30000

-

Type 2:

-

Aluminium PVD vacuum Coating Line

-

Coating Technology:

-

Evaporation or Sputtering

-

After-sales Service Provided 1:

-

Free spare parts

-

After-sales Service Provided 2:

-

Field maintenance and repair service

-

After-sales Service Provided 3:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Machine Type:

-

HCMS+CA-, Coating Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HCVAC

-

Voltage:

-

380v

-

Power:

-

30-50kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

30000

-

Type 2:

-

Aluminium PVD vacuum Coating Line

-

Coating Technology:

-

Evaporation or Sputtering

-

After-sales Service Provided 1:

-

Free spare parts

-

After-sales Service Provided 2:

-

Field maintenance and repair service

-

After-sales Service Provided 3:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

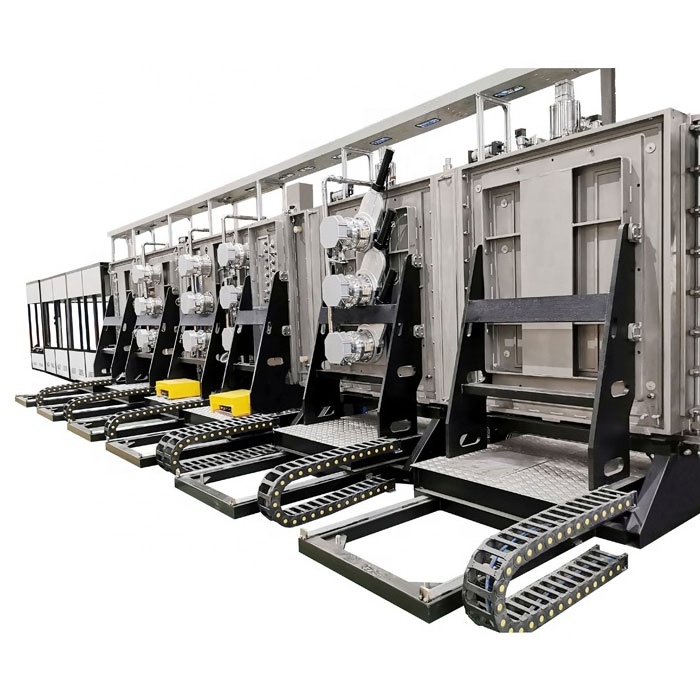

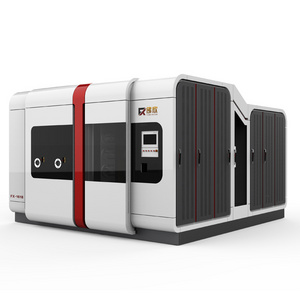

HCVAC Continuous Magnetron Sputtering Coating production line is mainly used in touch screen, acrylic, glass, ceramics, mobile shell, computers, PET, etc.. Coated high-quality, high-performance metal film, electromagnetic shielding film, reaction film, composite film, the transparent conductive film, radiation (AR), the reflection-increasing film, Aluminium glass mirror,color glass mirror,LOW-E film, etc.. The company can provide the design in demand of customer.At present, products and process throughout the country and overseas.

Whether it be architectural glass for facades, large display screens or special coatings, in all these cases large substrates are coated and millions of square meters receive highly complex functional layers which ultimately provide the desired properties. Piece by piece and with the highest precision and repeatability.

HCVAC provides the equipment to master the challenges of large-area coating for the applications mentioned above and many more. Modular design, optimized processes, energy efficiency, high throughput and accurate quality control are just some of the features you can expect from us.

Whatever your large-area application may be, HCVAC has the solution: from giant architectural glass coaters via precision display coating machines to sophisticated laboratory equipment.

Technical data

Substrate: GLASS,A crylic,PMMA ......

SIZE: 1830x2440m,2440x3660mm,2000MM*2500MM.... or customerize.

Application: LCD Panel,CIGS Thin-film photovoltaics,CdTe thin-film photovoltaics,Organic Photovoltaics,Aluminium mirror,color mirror,single Low-E, double Low-e, reflective glass,Window glass,Construction energy saving glass.

Target: Aluminium,stainless steel,silicon, ITO,SIO,TIO,ZNO,CRO,AZO,GZO,IGZO,METAL Layer and others

Power source: DC,PULSED DC or MF

Magntron type: Planar,single or dual rotatable

Type of transport: INLINE

Orientation of substrate during deposition: horizontal,LEL,SEL

System control: PLC

System dimensions: Min 20m*16.5m*3.5m and customerize

1. Large size chamber and large size glass applicable

2.High efficient cathode manufacturing technology

3. Partical control technology and film uniformity securing technology

*Most advanced five-section gas supply

* High configuration vacuum system, stainless steel route and connnection with high vacuum baffle valve

*Imported motor and timing belt

*Latest cathode layout tecnology

* Industrial Computer Control System+Programmable Login Controller

| APPLIED INDUSTRY |

Whole plant output:

*Monolithic glass touch panel whole plant output

*CIGS whole plant output

*4AR/6AR whole plant output

*Coil to Coil ITO film whole plane output

*Solar engergy whole plant output

*Electricaly induced discoloration whole factory output

We can design the whole system according to customer's requirements.