- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SINODER

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

refer to capacity

-

Weight:

-

10000 KG

-

function:

-

to extract oil from all kinds of oil cake

-

Raw material:

-

soybean oil cake, cottonseeds oil cake, sunflower oil cake, etc.

-

Application:

-

Edible Oil Production Line

-

Advantage:

-

Energy Saving Low Residual

-

Material:

-

Carbon Steel Stainless Steel

-

Capacity:

-

5-500t/d

-

Feature:

-

Multifunction High Efficient

-

Color:

-

Custom-made

-

Quality:

-

China Profesional High Quality

-

Product name:

-

50TPD n-hexane soybean solvent extraction plant

Quick Details

-

Max Capacity:

-

5-500t/d

-

Production Capacity:

-

98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SINODER

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

refer to capacity

-

Weight:

-

10000 KG

-

function:

-

to extract oil from all kinds of oil cake

-

Raw material:

-

soybean oil cake, cottonseeds oil cake, sunflower oil cake, etc.

-

Application:

-

Edible Oil Production Line

-

Advantage:

-

Energy Saving Low Residual

-

Material:

-

Carbon Steel Stainless Steel

-

Capacity:

-

5-500t/d

-

Feature:

-

Multifunction High Efficient

-

Color:

-

Custom-made

-

Quality:

-

China Profesional High Quality

-

Product name:

-

50TPD n-hexane soybean solvent extraction plant

50TPD n-hexane soybean solvent extraction plant with less than 1% oil residue

Brief introduction of solvent extraction plant

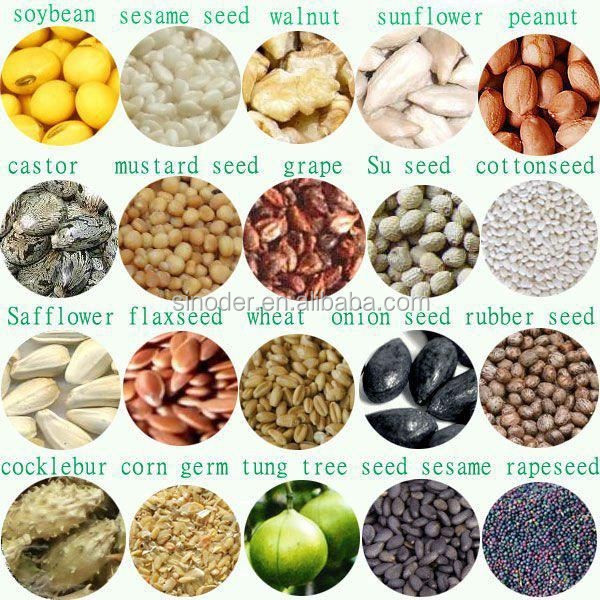

The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean fter flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower ,peanut ,cottonseed , palm kernel ,canola, copra ,castor, and variety of other vegetable seed raw material

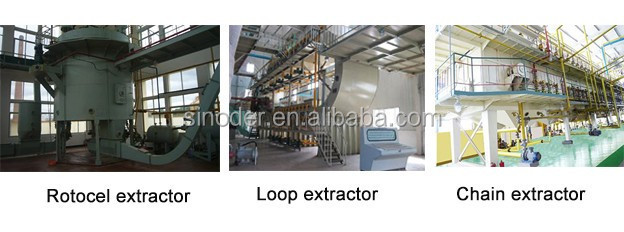

Main equipment and function :

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor;

(2) Rotocel extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be

dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3) DTDC: usd to separate the solvent from the wet meal.

(4) Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10%

saline water to it. The phospholipid and impurities in the miscella will react with the saline wter,

at last the reactant precipitate, reaching the goal of purifying.

(5) Miscella tank 2nd: the purified miscella will be pumped into it.

(6) Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be

discharged to condenser for recycling.

(7) Condensers : used to cooling the solvent gas separated from the wet meal and miscella for recycling.

what edible oil processing machines we supply?

Our Sinoder Indutech Machinery Company supply the complete set of Cooking oil production line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, jatropha seeds oil production line,moringa seeds oil production line and other vegetables oil processing machines.

Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm seeds and jatropha seeds.

We meet the demands of virtually every application in the vegetable oil processing industries. With premium quality oil mill machinery, oil extraction machines and professional oil processing systems & oil refining technologies in the field of vegetable oil extraction and refineries, you can depend on our equipment and expertise to help you hulling, crushing, conditioning, flaking, cooking, extruding, expelling, extracting, degumming, neutralizing,dewaxing/fractionation.

We (our Sinoder Company) supply small scale oil press machines for home or village use, Hydraulic Oil Press Machine for small scale oil factory and home use, large scale production oil screw pressing line and oil refinery lines for commercial production factory use.

Sinoder Brand 6YL Series Small Scale Oil Press Machines (for home or village family workshop use)

Sinoder Brand 6YL Series Small Scale Oil Press Machines Parameters:

|

Model |

6YL-60 |

6YL-80 |

6YL-100 |

6YL-120 |

6YL-160 |

|

|

Dia. |

φ 53mm |

φ 81mm |

φ 101mm |

φ 123mm |

φ 160mm |

|

|

Screw speed |

64r/min |

47r/min |

38r/min |

35r/min |

32r/min |

|

|

Motor Power |

Motor |

1.5-2.2kw |

5.5kw |

7.5kw |

11kw |

22kw |

|

Vacuum pump |

0.18kw |

0.55kw |

0.75kw |

1.1kw |

2.2kw |

|

|

Heater |

0.9kw |

2.2kw |

2.2kw |

2.2kw |

0.9kw |

|

|

Capacity |

40-60kg/h |

80-100kg/h |

150-200kg/h |

250-300kg/h |

500-600kg/h |

|

|

Weight |

268kg |

880kg |

1250kg |

1500kg |

1800kg |

|

|

Size (mm) |

1020×720 ×798 |

1500×1200 ×1750 |

2000×1300 ×1850 |

2100×1300 ×1850 |

2300×1300 ×1950 |

|

Sinoder Brand 6YZH Series Hydraulic Oil Press Machine for small scale oil factory and home use

Sinoder Brand 6YZH Series Hydraulic Oil Press Machine Parameters:

Large scale screw Oil pressing Machine for commercial oil factory use

Sinoder Brand ZX/ZY Series Screw Oil Expeller Machine Parameters:

♦ Cleaning process : Use vibration cleaning sieve and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc.

♦ Crushing Process: This Process is mainly to crush the peanut , as the peanut is big ,it is not easy to press .We must crush the peanut to 6-8 pieces,then we need to peel .The rate of peel is about 90%.

♦ Flaking Process : After crush and peel ,we need to flake the crushed sunflower , which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..

♦ Cooking Process: After the flaker,we need to cook the flaked sunflower , control the moisture at 5-7% ,the temperature is 110-115degree.

♦ Oil-pressing : After all the pretreatment , pre- press the sunflower , the oil can be extracted about 76% .

♦ Primary Oil Filtering Process: after the oil pressing, the crude oil will be primary filtered and for store to tank or for next process of oil refinery.

Solvent Extraction, as the name suggests is a process to extract the oil from oil bearing materials by means of Solvent, Solvent used being normal Hexane – a petroleum bye product.

The plant is designed to extract oil directly from oil seed containing less than 20% oil like soyabean after flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Edible oil refining contains vegetable oil refining, animal oil refining, microbial oil refining. The crude oil refining production line can remove impurity of oil and obtain high quality standard finished refined oil through washed

degumming

, alkali refining soap removal, mixed proportion, blenching, filtration, physical deacidification and deodorization, crystallization and maturing and including following process:

Decolorizing / Bleaching:

Remove color pigments contained in oil

Deodorizing

: Remove disagreeable flavor and odors that are naturally present or created during processing under high temperatur

Dewaxing (Optional):

Oils like sunflower oil or maize germ oil (corn oil) have waxes present in them. At low temperatures these waxes give a hazy appearance to the oil. So, in extremely cold areas, dewaxing should take into accout when processing these oil seeds.

We supply oil refining machines system with capacity from 1ton per day to 600 tons per day.