- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

blade shredder double shaft shredder knives for shredder

-

Precision:

-

Within 0.005mm

-

Surface Treatment:

-

Rust Proofing Treatment

-

Type:

-

Machine Blade

-

Hardness:

-

58-60 HRC

-

Capacity:

-

200KG-3000KG

-

Delivery Time:

-

15-20 days

-

Advantage:

-

High hardness and precision

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WANGGUO

-

Weight (KG):

-

90

-

Product name:

-

blade shredder double shaft shredder knives for shredder

-

Precision:

-

Within 0.005mm

-

Surface Treatment:

-

Rust Proofing Treatment

-

Type:

-

Machine Blade

-

Hardness:

-

58-60 HRC

-

Capacity:

-

200KG-3000KG

-

Delivery Time:

-

15-20 days

-

Advantage:

-

High hardness and precision

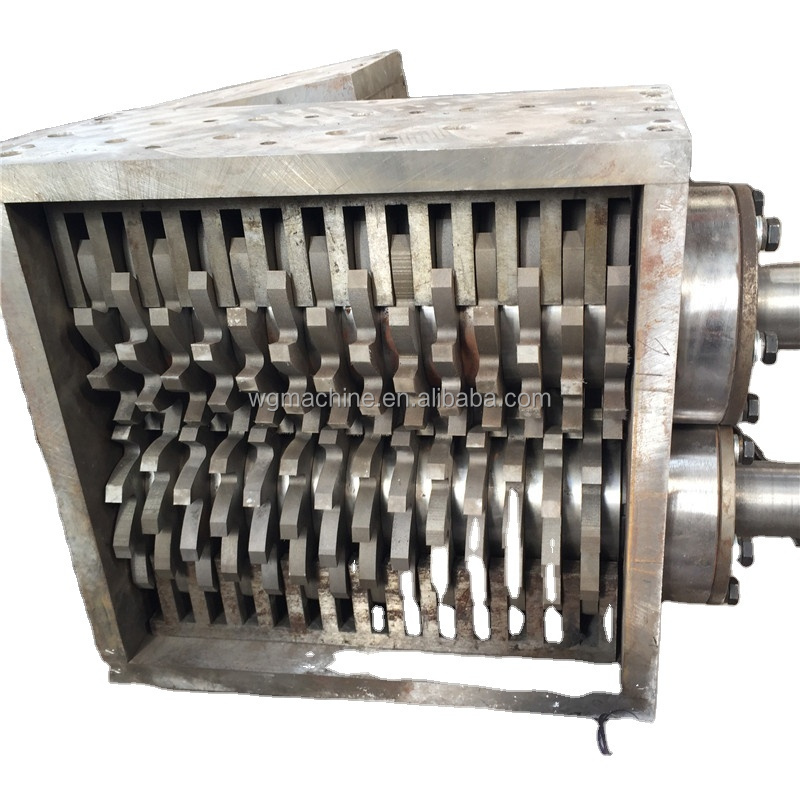

blade shredder double shaft shredder knives for shredder

|

Product name

|

shredder blade

|

|

Material

|

HSS; SKD11; SKD61; Cr12Mov; or selected by the customers

|

|

Hardness

|

58-60 HRC (by the material selected)

|

|

Dimension tolerance

|

OD:±0.1, ID:±0.03 -0.00, Thickness: ±0.03

|

|

OEM service

|

Available

|

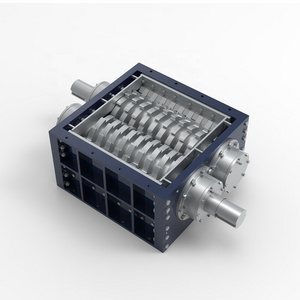

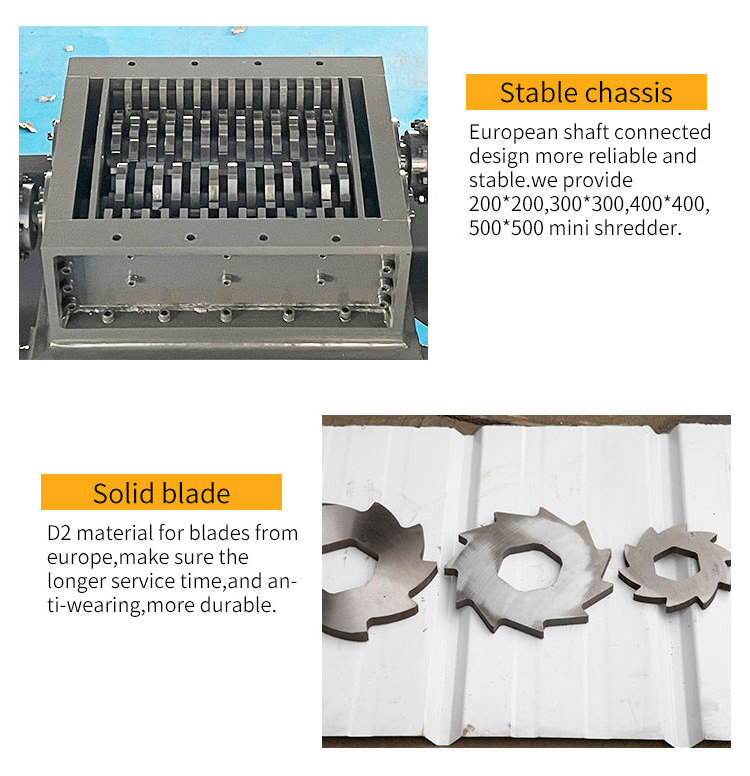

Multi shaft shredder blade

Multi-axis shredding machine blade for claw, according to the design of each company, shredding machine installed in biaxial or four axis, generally can be divided into three claw shredding machine blade, 8 claw shredding machine, 12 claw shredding machine blade, etc, used for crushing, tearing and extrusion to decrease the size of the material, the shredding machine blades are widely used in waste plastics, waste rubber, wood and other large volume of waste.

CR12MOV and skd-11 are cold-working die steel, which have similar properties, strong wear resistance and impact resistance, suitable for tearing up wood, used furniture and plastic with high hardness.

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We'll run the blade on the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.