▲

▲

▲

▲

▲

▲

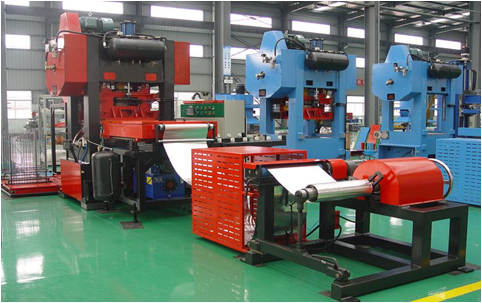

1. Machine Line includes: Coil Cradle, Oil tank, feeder, Power press, Sucker & Collector, Air system, Electric system, Hydraulic System.

2. Vacuum Stucker is controlled by converter

3. Collector has protecting system for fault operation, No material warning, no oil warning

4. The slide of power press has hydro-lifting function which will be convenient for dies installation / commissioning

5. Hydraulic rapid-dies changing device

6. PLC control

7. Industrial touch-screen controller

8. Photo-electric protecting device

9. Hydraulic overloading system: