- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

40-150pcs/min

-

Weight (KG):

-

1100

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SOULYAM

-

Dimension(L*W*H):

-

2800x2800x1800mm

-

Product name:

-

Automatic Alcohol Prep Pad Making Machine

-

Bag type:

-

Four Side Seal

-

Control system:

-

PLC+Servo+Touch Screen

-

Packing speed:

-

70 - 130 bags/min

-

Material:

-

PE/OPP,PE/PET, paper film, aluminum laminated films, Composite film

-

Bag size range:

-

(L)40-130mm (W)40-80mm

-

Alcohol Pad Unfold Size:

-

(L):40-240mm , (W):30-240mm

-

Raw Material:

-

Air-laid paper, wet strength paper, spun lace non-woven fabric

-

Roller Film Width:

-

80-260mm

-

Folding option:

-

Max.10 folding vertical,4 folding horizontal

-

Marketing Type:

-

New Product 2022

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing, SLITTING, counting

-

Packaging Type:

-

case

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

40-150pcs/min

-

Weight (KG):

-

1100

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SOULYAM

-

Dimension(L*W*H):

-

2800x2800x1800mm

-

Product name:

-

Automatic Alcohol Prep Pad Making Machine

-

Bag type:

-

Four Side Seal

-

Control system:

-

PLC+Servo+Touch Screen

-

Packing speed:

-

70 - 130 bags/min

-

Material:

-

PE/OPP,PE/PET, paper film, aluminum laminated films, Composite film

-

Bag size range:

-

(L)40-130mm (W)40-80mm

-

Alcohol Pad Unfold Size:

-

(L):40-240mm , (W):30-240mm

-

Raw Material:

-

Air-laid paper, wet strength paper, spun lace non-woven fabric

-

Roller Film Width:

-

80-260mm

-

Folding option:

-

Max.10 folding vertical,4 folding horizontal

-

Marketing Type:

-

New Product 2022

Products Description

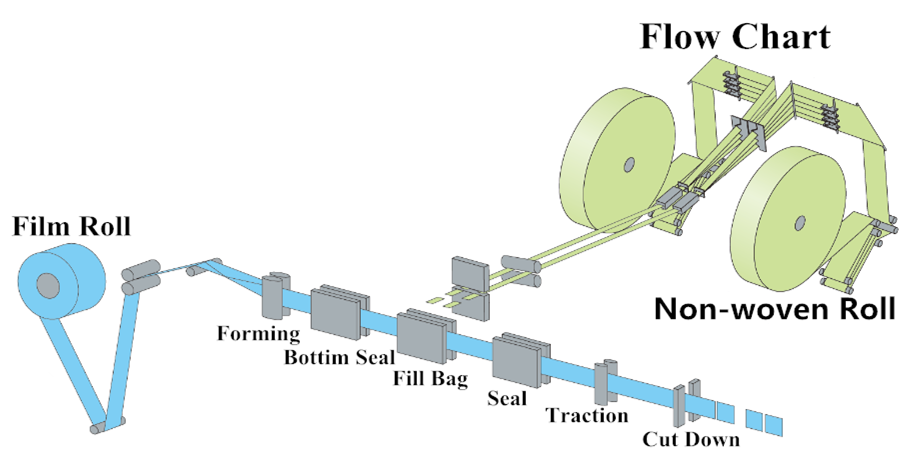

AWP-250 Fully Automatic Wet Wipes Production Line/Alcohol Prep Pads Packing Machine

|

Model

|

AWP-250

|

|

Packaging Form

|

Four-size Sealing

|

|

Packing Material

|

PE/OPP,PE/PET,CPP,BOPP/PE, paper film, aluminum laminated films, Composite film

|

|

Inner Material

|

30-90gsm Air laid paper, nonwoven, spun lace nonwoven fabric etc.

|

|

Material Inner Roller Dia.

|

Φ70-75MM

|

|

Bag size range

|

(L)40-140mm (W)40-110mm

|

|

Wet Wipes Unfold Size

|

(L):40-240mm , (W):30-240mm

|

|

Folding Way

|

Max 10 folding vertical, and 4 folding horizontal

|

|

Liquid Added Range

|

0-10ml

|

|

Packing Speed

|

70-130 PCS/M

|

|

Total Power

|

6KW

|

|

Power Supply

|

Single-phase two-wire 220V 50/60 or 3 phase 380V

|

|

Machine Noise

|

≤64.9dB(A)

|

|

Air Supply

|

0.6-1.0 MPa

|

|

Air Consumption

|

≥0.2m³/minute

|

|

Packing Box Dimensions

|

3600x1100x1950mm

|

|

Machine Weight

|

1200kgs

|

Product Featrues

1. Four sides sealing package bag,it makes your product looks nicer and different from the normal product in the market.

2. The machine use top quality brands component parts for drive and control system,ensure the stable,reliable and durable operation.

3. Wide selection of operation language available in touch screen,including English,Arabic,Spanish,French,Korean,Japanese,Russian etc.

4. Easy tear V type notch device,to make your wet wipe friendly and easy use to customer.

5. Nice date coding device,same as pharmaceutical machinery standard.

6. The machine uses Electro-Optical Sensor System(EOSS) to realize automatic alignment on the packing films and guarantee the same appearance of each bag.

7. Machine runs at low DB,make your workshop low noisy.

8. The maintenance cost is low because of few damageable assemblies.

9. Highly automation,one person allowed to control several sets of machines.

10. Intellegient mechanical manipulator for wet wipe output control

11. Glass cover to ensure safe and clean operation.

2. The machine use top quality brands component parts for drive and control system,ensure the stable,reliable and durable operation.

3. Wide selection of operation language available in touch screen,including English,Arabic,Spanish,French,Korean,Japanese,Russian etc.

4. Easy tear V type notch device,to make your wet wipe friendly and easy use to customer.

5. Nice date coding device,same as pharmaceutical machinery standard.

6. The machine uses Electro-Optical Sensor System(EOSS) to realize automatic alignment on the packing films and guarantee the same appearance of each bag.

7. Machine runs at low DB,make your workshop low noisy.

8. The maintenance cost is low because of few damageable assemblies.

9. Highly automation,one person allowed to control several sets of machines.

10. Intellegient mechanical manipulator for wet wipe output control

11. Glass cover to ensure safe and clean operation.

Product Details

Air Shaft

Iwaki Liquid Pump

Panasonic Color Mark Sensor

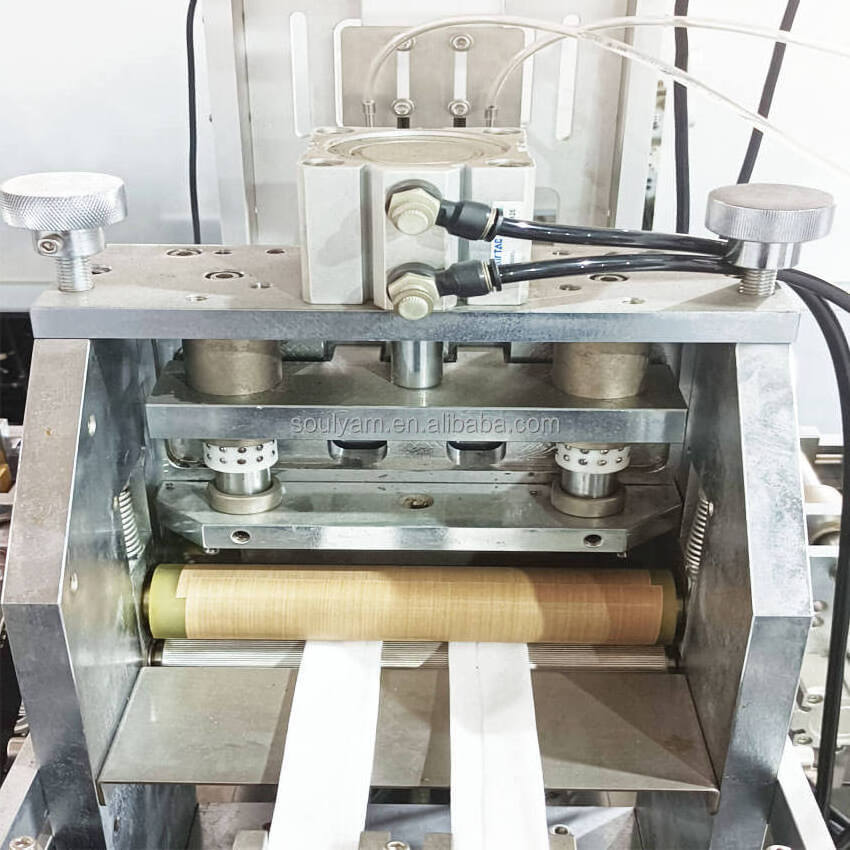

Bottom Sealing + Left Side Right Side Sealing(First Time)

Two Unwinding Station With Folding Board

Feeding the Non-woven Fabrics

Cutter

Filling Liquid into Bag

Integral arc folding device

Left Right Side Sealing(Second Time) &Top Side Sealing

Make Batch Number and Easy Tear Hole Station

Output finished wipes bag by Robot Arm

Sample Display

Hot Searches