- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/440V

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

upon equipment model

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

CANGAS Central oxygen supply system

-

Oxygen Purity:

-

93%

-

Oxygen Capacity:

-

1-200Nm3/h

-

Oxygen Dew point:

-

≤-45℃~-50℃

-

Oxygen Outlet pressure:

-

≤4bar/Customized

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

Standard:

-

GB/ASME/Customized

-

Distribution:

-

Acceptable

-

Certification:

-

CE,BV,ISO,GC3

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

CANGAS

-

Production Rate:

-

1-200Nm3/h

-

Voltage:

-

220/380/440V

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

upon equipment model

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

CANGAS Central oxygen supply system

-

Oxygen Purity:

-

93%

-

Oxygen Capacity:

-

1-200Nm3/h

-

Oxygen Dew point:

-

≤-45℃~-50℃

-

Oxygen Outlet pressure:

-

≤4bar/Customized

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

Standard:

-

GB/ASME/Customized

-

Distribution:

-

Acceptable

-

Certification:

-

CE,BV,ISO,GC3

It ends days when medical facilities have to rely on traditional costly liquid oxygen and cylinder oxygen.

CANGAS® CAP-O series hospital oxygen gas supply system is specifically designed for medical facilities central oxygen supply, passed related medical equipment Registration Certification, and as medical gas, it meets the United States Pharmacopoeia (UPS) XXI Oxygen 93% Monograph.

CANGAS® hospital oxygen gas supply system wins good reputation from the customers from China Mainland, Kazakhstan, USA, Angola, Myanmar etc.

| CANGAS® PSA Oxygen Generator | ||||||

|

Capacity

(Nm3/h) |

Model | Dimensions(mm) | Inlet | Outlet | ||

| L | W | H | ||||

| 4 | CAPO-4 | 1050 | 600 | 1700 | DN15 | DN15 |

| 5 | CAPO-5 | 1150 | 600 | 1620 | DN15 | DN15 |

| 10 | CAPO-10 | 1300 | 700 | 1750 | DN15 | DN15 |

| 15 | CAPO-15 | 1450 | 750 | 2120 | DN15 | DN15 |

| 20 | CAPO-20 | 1550 | 800 | 2250 | DN15 | DN15 |

| 25 | CAPO-25 | 1550 | 800 | 2700 | DN20 | DN15 |

| 30 | CAPO-30 | 1550 | 850 | 2700 | DN20 | DN15 |

| 40 | CAPO-40 | 1750 | 900 | 2900 | DN20 | DN15 |

| 50 | CAPO-50 | 1850 | 950 | 3100 | DN25 | DN15 |

| 60 | CAPO-60 | 1900 | 1060 | 3210 | DN65 | DN25 |

| 100 | CAPO-100 | 2000 | 1200 | 3700 | DN80 | DN25 |

| 200 | CAPO-200 | 2450 | 1400 | 4500 | DN125 | DN40 |

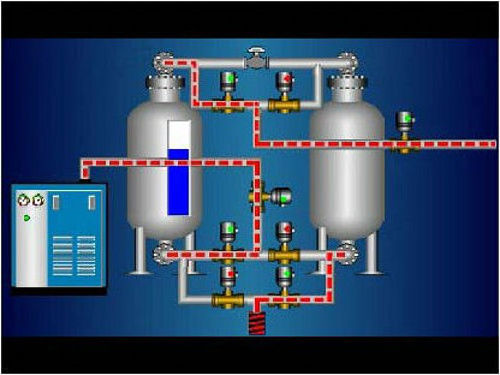

The PSA oxygen technology process for the generation of oxygen gas from compressed air utilizes the ability of Zeolite Molecular Sieve (ZMS) to absorb mainly nitrogen. While nitrogen concentrates in the pore system of the ZMS, purity oxygen gas is produced as a product.

Features

-Professional expertise in oxygen treatment for fish

-Small investment, no material consumption except power

-Minimal maintenance with small operating spares

-Energy Efficiency System (EES) optional for O2 flow variety to save power

CAN GAS Systems Company Limited, identified as the Beijing Key High-tech Corporation, is one of the initial companies involved in air separation industry. CAN GAS is committed to continuously providing core value to customers in all industries. With 28,000 square meters’ production base, five national patents and ISO9001:2008 Certificate of Quality Management System Certification, CAN GAS has been an integration of R&D, design, manufacture, sales, service. Over the past ten years, CAN GAS has successfully provided over 4000 sets of air separation systems for many industries in over 100 countries and regions.

CAN GAS Systems have a range of PSA nitrogen & oxygen generators, membrane nitrogen & oxygen generators, nitrogen purification systems etc, and are widely used in industries of petroleum, oil & gas, chemicals, electronics, metallurgy, coals, pharmaceuticals, aerospace, autos, glass, plastics, food, medical treatment, grain, etc. With years research in air separation technology and rich solution experiences in various industries, CAN GAS sticks to providing our clients with more reliable, more economical, more convenient professional gas solutions.

By now we have supplied CANGAS® systems for clients including GE USA, WILMAR International Singapore, DEGUSSA Group Germany, SAMSUNG, ORION Korea, China Petrol, Sinopec, etc. CAN GAS has built up a global distributor system covering Russia, Bangladesh, Indonesia, Pakistan etc. During the 2008 Olympics, CAN GAS was selected by Beijing Food Safety Test Center as the supplier for nitrogen generator to test the Olympic food.

We have an experienced professional team always ready to be at your service. The sales engineers carefully analyze your specified requirements and offer suitable solutions for you. The after-sale service system guarantees swift response to your problems within 24 hours and their resolutions in the shortest time. CAN GAS is responsible for after-sales services to nitrogen/oxygen generators and other related equipment offered by us. Besides, CAN GAS global distributor system can provide prompt professional localized service.

CAN GAS is dedicated to supplying with our customers with more reliable, more economical and more convenient air separation solutions and professional service.

Prpduce Processes

Warranty & Site Services

The Guarantee/Warranty Period shall be a period of twelve (12) months after on-site startup & commissioning or eighteen (18) months after shipment, whichever occurs first.

If any trouble or defect, originating with the design, material, workmanship or operating characteristics of any Goods, arises at any time during GUARANTEE/WARRANTY period, CAN GAS shall, at his own expense and as promptly as possible, make such alterations, repairs and replacements as may be necessary to permit the Goods to function in accordance with the specifications and to fulfill the foregoing guarantees.

Site service

CAN GAS can do paid services of on-site startup, commissioning, installation supervision, training, by providing purchaser with the services of qualified English-speaking engineers at users site, by sending English-speaking engineer to users site.

CAN GAS shall obtain all permits and licenses required to perform the services under this Agreement.

CAN GAS will provide his personnel with valid visas, in maximum 10 days mobilization to site.

Customer visiting:

Trade shows:

Shipping and packing:

|

---Successful industrial Cases

---Successful Medical& Hospital Cases

1. What's the order to have an oxygen or nitrogen generator plant ?

a. Inquiry---provide us all clear requirements.

b. Quotation---official quotation form with all clear specifications.

c. Contract confirmation---provide correct contract details.

d. Payment terms

e. Production

f. Shipping

g. Installation and commissioning

h. Conducting routine after sales support

2. How to get a prompt quotation of Oxygen or Nitrogen Generator?

When you send the inquiry to us, pls kindly send it with below technical information.

1) O2/N2 flow rate: _____Nm3/hr( or How many cylinders/ liquid do you consume per day(24hours))

2) O2/N2 purity: _____%

3) O2/N2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/___PH/___HZ

5) Application:

6) Project Location:

7) Job site altitude___, ambient temperature___

8) Machine room availability Y/N