- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2023

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

minderhightech

-

Weight (KG):

-

600

-

Marketing Type:

-

Hot Product 2023

Products Description

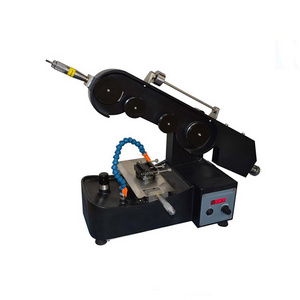

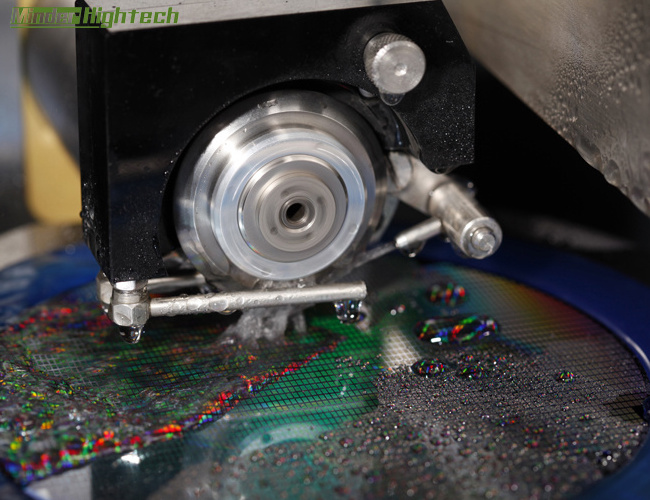

DS820--precision dicing machine

DS820

The precision dicing machine is equipped with a 15-inch LCD touch screen, with a friendly GUI interface, and easy and convenient to align the workpiece; using the DS-300 software control system, the frame is reasonable, the operation is convenient, and the production efficiency is improved; the equipment has stable performance, high reliability, and maintenance cost Low.

Specification

|

Configuration and performance

|

Processing size

|

φ200mm or φ180mm

|

|

|

Groove depth

|

≦4mm or customized

|

|

|

Flatness of worktable

|

±0.005mm/100mm

|

|

|

Alignment system

|

70*Straight light﹢Ring light (210*optional)

|

|

Spindle

|

range of rotation

|

10000~50000rpm

|

|

|

Output Power

|

1.5KW

|

|

X axis

|

Drive way

|

servo motor

|

|

|

Workbench left and right stroke

|

380mm

|

|

|

Stroke resolution

|

0.001mm

|

|

|

Speed setting range

|

0.1~400mm/s

|

|

Y axis

|

Drive way

|

Stepping motor ﹢ grating closed loop control system

|

|

|

Spindle back and forth stroke

|

210mm

|

|

|

Stroke resolution

|

0.0005mm

|

|

|

Single-step positioning accuracy

|

≦0.003mm/5mm

|

|

|

Full positioning accuracy

|

≦0.005mm/210mm

|

|

Z axis

|

Drive way

|

Stepper motor

|

|

|

Spindle up and down stroke

|

30mm

|

|

|

Stroke resolution

|

0.001mm

|

|

|

Repeatability

|

0.001mm

|

|

θ axis

|

Drive way

|

DD motor

|

|

|

Angle range

|

380º

|

|

|

Angle resolution

|

0.0005º

|

|

Basic specifications

|

power supply

|

Single phase, AC220±10%, 3.0kVA

|

|

|

power consumption

|

0.6KW during processing (reference value)

|

|

|

|

When warming up 0.4KW (reference value)

|

|

|

Compressed air

|

Pressure 0.5~0.6Mpa, maximum consumption 180L/min

|

|

|

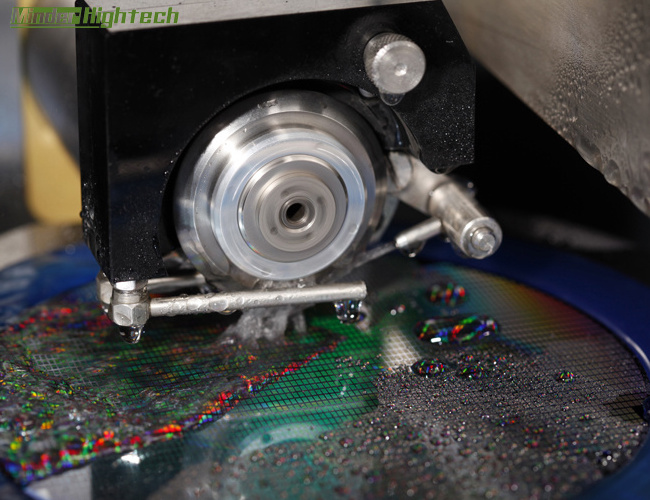

Cutting water

|

Pressure 0.2~0.3Mpa, maximum consumption 3.0L/min

|

|

|

Cooling water

|

Pressure 0.2~0.3Mpa, maximum consumption 1.5L/min

|

|

|

Exhaust volume

|

2.0m³/min(ANR)

|

|

|

Dimensions W×D×H

|

775mm*960mm*1650mm

|

|

|

weight

|

600kg

|

DS830--precision dicing machine

DS830

The precision dicing machine is equipped with an imported 1.5kw high-speed spindle; driven by the θ-axis DD motor, the accuracy of the rotation angle, the resolution of the rotation angle, and the flatness of the table are improved; the power distribution system is upgraded, and multiple functions can be selected according to customer needs.

Specification

|

Configuration and performance

|

Processing size

|

φ200mm or φ180mm

|

|

|

Groove depth

|

≦4mm or customized

|

|

|

Flatness of worktable

|

±0.005mm/150mm

|

|

|

Alignment system

|

70x straight light﹢ring light (210+optional)

|

|

Spindle

|

range of rotation

|

10000~50000rpm

|

|

|

Output Power

|

1.5KW (2.4KW optional)

|

|

X axis

|

Drive way

|

servo motor

|

|

|

Workbench left and right stroke

|

380mm

|

|

|

Stroke resolution

|

0.001mm

|

|

|

Speed setting range

|

0.1~500mm/s

|

|

Y axis

|

Drive way

|

Stepping motor ﹢ grating closed loop control system

|

|

|

Spindle back and forth stroke

|

210mm

|

|

|

Stroke resolution

|

0.0005mm

|

|

|

Single-step positioning accuracy

|

≦0.003mm/5mm

|

|

|

Full positioning accuracy

|

≦0.005mm/210mm

|

|

Z axis

|

Drive way

|

Stepper motor

|

|

|

Spindle up and down stroke

|

30mm

|

|

|

Stroke resolution

|

0.001mm

|

|

|

Repeatability

|

0.001mm

|

|

θ axis

|

Drive way

|

DD motor

|

|

|

Angle range

|

380º

|

|

|

Angle resolution

|

0.0002º

|

|

Basic specifications

|

power supply

|

Single phase, AC220±10%, 3.0kVA

|

|

|

power consumption

|

0.6KW during processing (reference value)

|

|

|

|

When warming up 0.4KW (reference value)

|

|

|

Compressed air

|

Pressure 0.5~0.6Mpa, maximum consumption 220L/min

|

|

|

Cutting water

|

Pressure 0.2~0.3Mpa, maximum consumption 3.5L/min

|

|

|

Cooling water

|

Pressure 0.2~0.3Mpa, maximum consumption 1.5L/min

|

|

|

Exhaust volume

|

2.0m³/min(ANR)

|

|

|

Dimensions W×D×H

|

775mm×960mm×1650mm

|

|

|

weight

|

600kg

|

Detail

Features:

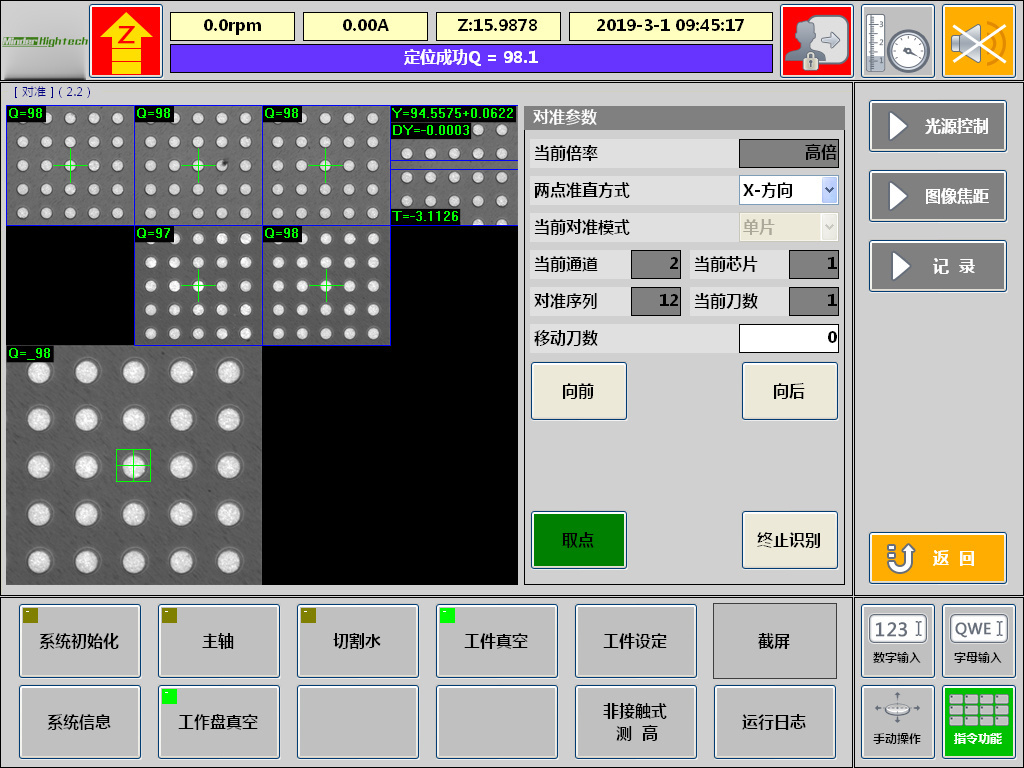

√ Blade database management

√ Workpiece cutting database management

√ Auto focus function

√ Two-way lifting knife cutting function

√ Compensation function for blade exposure

√ Multiple safety guarantees and alarm functions

√ Workpiece cutting database management

√ Auto focus function

√ Two-way lifting knife cutting function

√ Compensation function for blade exposure

√ Multiple safety guarantees and alarm functions

Conditions of Use:

1. Please set the machine in an environment of 20~25ºC (the fluctuation range is controlled within ±1ºC); the indoor humidity should be 40%~60%, keep constant without condensation.

2. Please use clean compressed air with atmospheric pressure dew point below -15ºC, residual oil content of 0.1ppm and filtration degree above 0.01um/99.5.

3. Please control the water temperature of the cutting water to room temperature 2ºC (fluctuation range within ±1ºC), and control the cooling water temperature to be the same as room temperature (fluctuation range control within ±1ºC).

4. Please avoid the device from gravitational impact and any external vibration threats. In addition, please do not install the equipment near blowers, vents, devices that generate high temperatures, and devices that generate oil.

5. Please install this equipment on a waterproof floor and a place with drainage treatment.

6. Please operate strictly in accordance with the company's product instruction manual.

2. Please use clean compressed air with atmospheric pressure dew point below -15ºC, residual oil content of 0.1ppm and filtration degree above 0.01um/99.5.

3. Please control the water temperature of the cutting water to room temperature 2ºC (fluctuation range within ±1ºC), and control the cooling water temperature to be the same as room temperature (fluctuation range control within ±1ºC).

4. Please avoid the device from gravitational impact and any external vibration threats. In addition, please do not install the equipment near blowers, vents, devices that generate high temperatures, and devices that generate oil.

5. Please install this equipment on a waterproof floor and a place with drainage treatment.

6. Please operate strictly in accordance with the company's product instruction manual.

Application areas:

diodes, triodes, LED packaging, NTC, MEMS, IC, photovoltaics, medical devices, scintillation crystals

Precision cutting materials

silicon wafer, PCB board, EMC, ceramics, glass, quartz, gallium arsenide, lithium niobate, sapphire, crystal

Auto focus function:

Through the visual algorithm, coordinated with the motion control, the lens can be automatically raised and lowered, and the clear position of the workpiece image can be quickly obtained.

Accessories Consumables

Application field

Brand customers

Well-known company

Colleges and universities

Factory

Hot Searches