- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Power:

-

15kW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

5500

-

Fan motor power:

-

5.5Kw

-

Fan motor:

-

1pc

Quick Details

-

Machine Type:

-

Automatic powder coating line, Spray Booths, Conveying Equipment, Curing oven, Coating Equipment, Powder Coating Line

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Voltage:

-

380V/220V

-

Power:

-

15kW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

5500

-

Fan motor power:

-

5.5Kw

-

Fan motor:

-

1pc

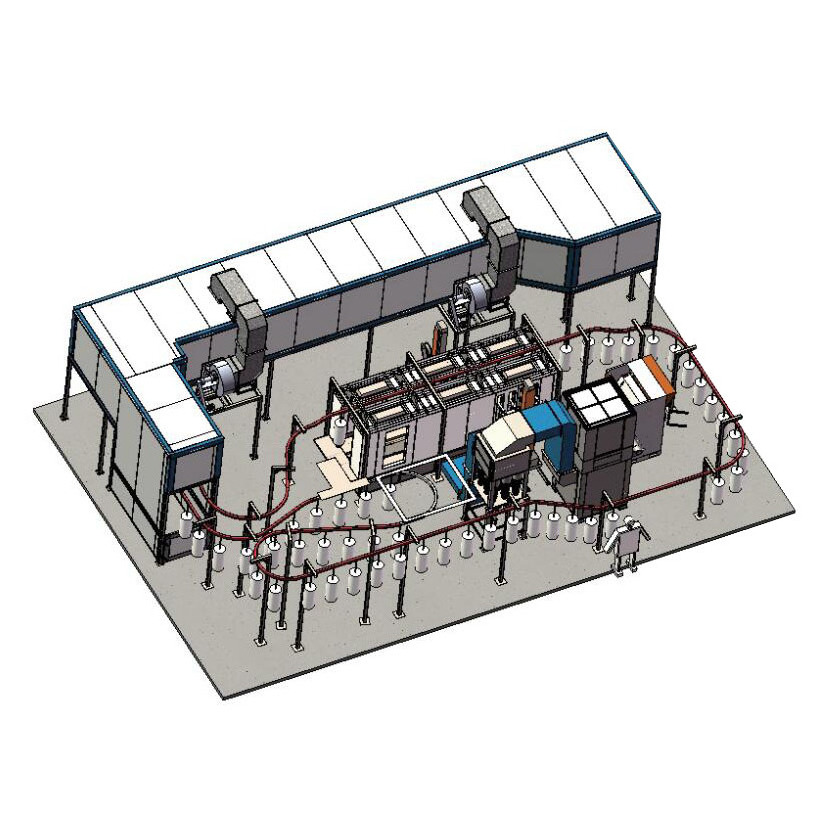

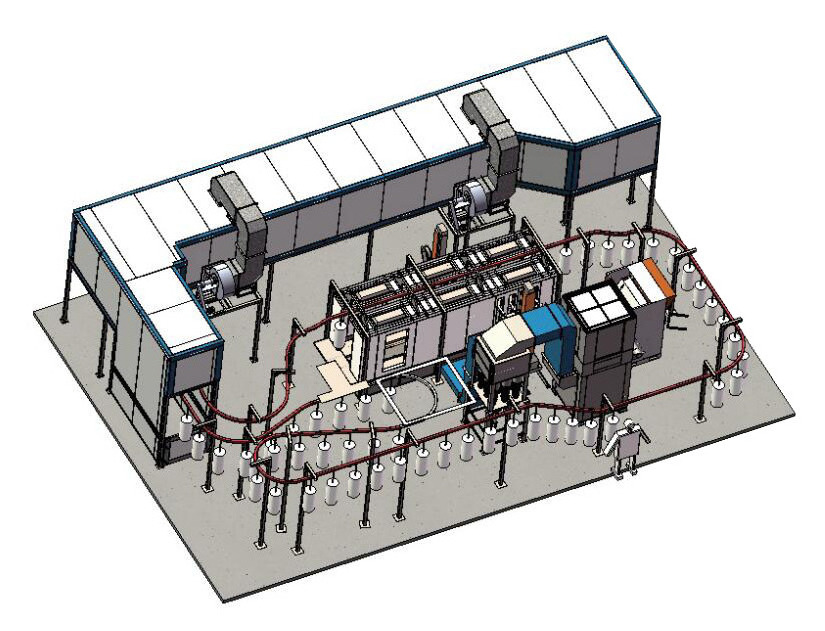

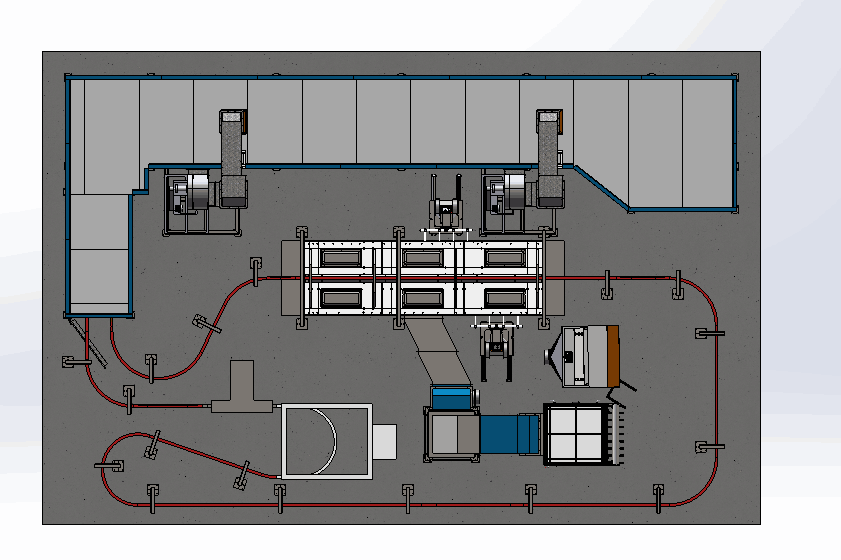

Automatic Powder Coating Spray Painting Line with Overhead Conveyor System

This is a design for a

ustralia

customer has limited workshop space, this full automatic powder coating line mainly include the automatic powder coating cyclone booth and the bridge oven and the automatic conveyor system.

The automatic powder coating booth equipment is a key part of high efficiency powder coating line system. It is not only setup for simple spraying but also comes with two step powder recovery system that is cyclone and after filter recovery units, to achieve fast color change and powder recovery, especially applicable in automatic powder coating line requiring quick color change.The bridge oven is grate to keep the curing air from loose.

|

Powder coating booth

|

with the multi-cyclone and after filter powder recycle system

|

|

|

|

|||

|

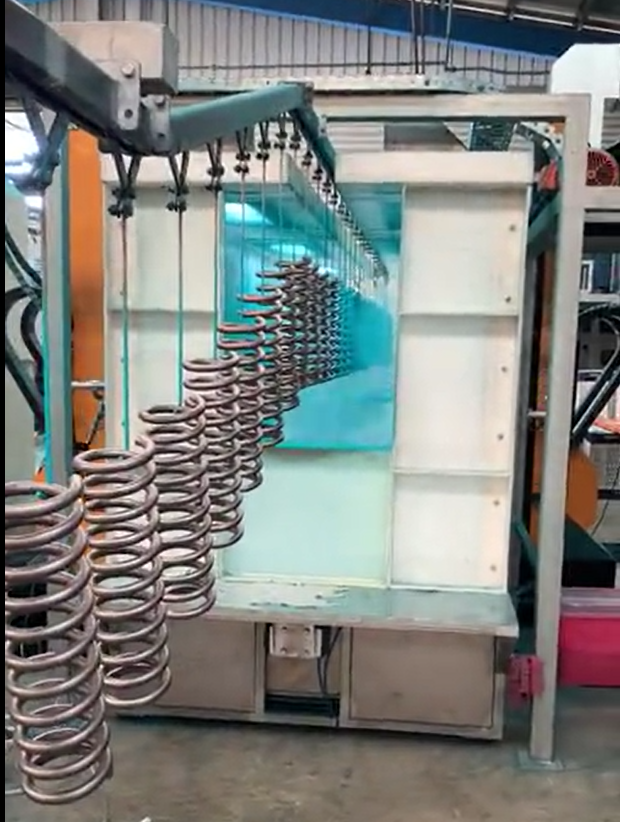

Conveyor system

|

automatic conveyor line on the powder coating booth

|

|

|

|

|||

|

Powder coating oven

|

The tunnel curing oven for designed for continuous operations

|

|

|

|

|||

|

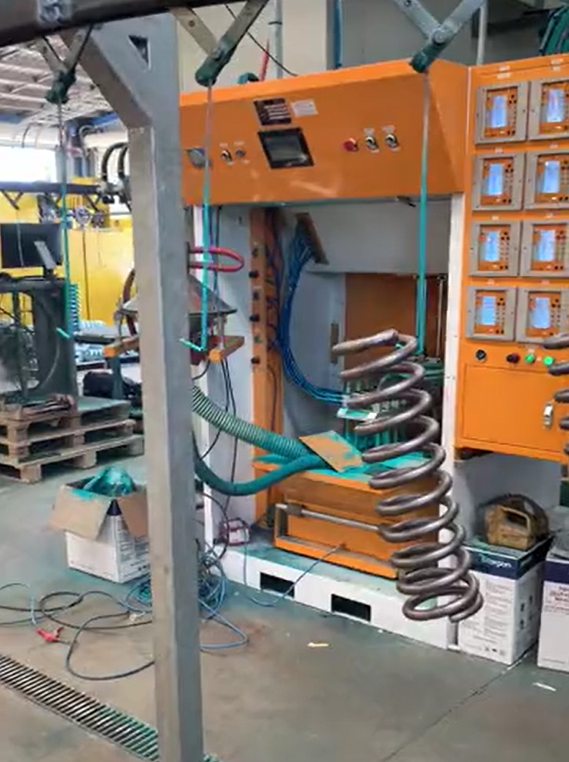

Automatic powder coating system

|

reciprocator ,automatic powder coating guns, powder feed center

|

|

|

|

|||

COLO-2000D reciprocator with COLO-191S automatic powder coating gun is a perfect set for automatic powder coating , the failure rate is low, frequent maintenance is not required, the service life is long, and the spraying quality is excellent.

We are a typical Chinese supplier and specialized in the research, development and production of powder coating equipments, such as powder coating gun, reciprocator, powder coating booth, powder coating oven, semi-auto powder coating line and full auto powder caoting line and so on. We also supply various kinds of powder caoting spare parts to our customer. We insist in offering superior quality products and efficient service.

If you are intereted in our products,please feel free to contact us.

We commited to your satisfactory and safety, if you are interested in our products,please feel free to contact us,thank you!

For small parts or powder coating machines, they will be packed with wooden case for good safety.

For powder coating booths and ovens, we will pack with foams and films and ship into a full container.