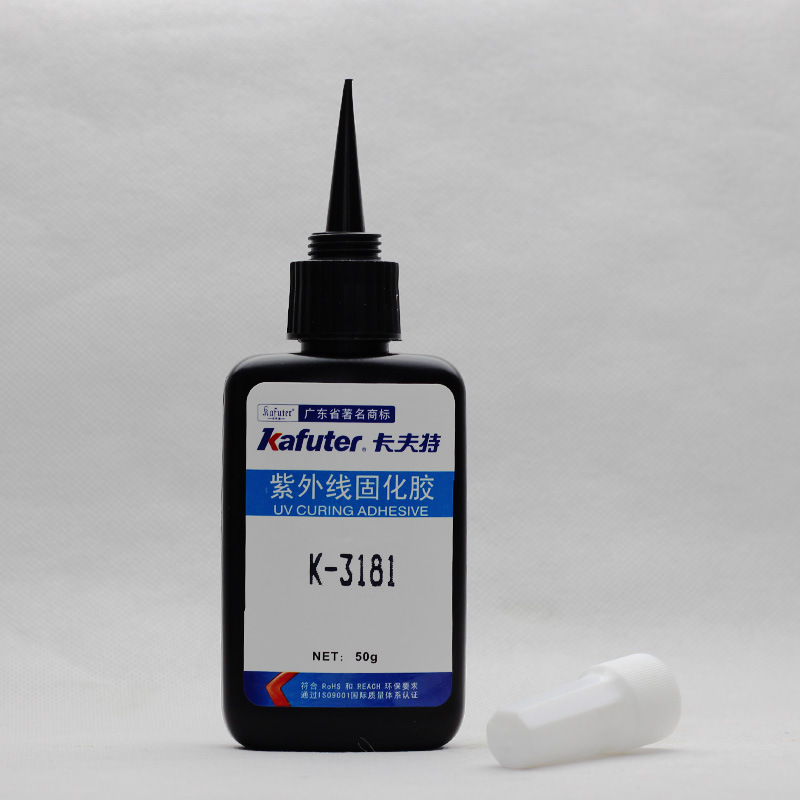

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

TQ2700000

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kafuter

-

Model Number:

-

k-3181-50g

-

Type:

-

uv glue

-

appearance:

-

Yellowish transparent liquid

-

Viscosity CPS:

-

10000~15000

-

Hardness (d):

-

55

-

Curing energy MJ:

-

1000

-

Certificate:

-

ISO9001/ ISO16949

-

Packing:

-

50g/piece, 80pieces/carton

Quick Details

-

CAS No.:

-

868-77-9

-

Other Names:

-

uv glue

-

MF:

-

(C4H6O2)x

-

EINECS No.:

-

TQ2700000

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kafuter

-

Model Number:

-

k-3181-50g

-

Type:

-

uv glue

-

appearance:

-

Yellowish transparent liquid

-

Viscosity CPS:

-

10000~15000

-

Hardness (d):

-

55

-

Curing energy MJ:

-

1000

-

Certificate:

-

ISO9001/ ISO16949

-

Packing:

-

50g/piece, 80pieces/carton

Products Description

K-3181 is a high strength UV curable acrylic adhesive with excellent adhesion to glass, metal and plastic substrates such as ABS,PVC, PS and PMMA.The adhesive has high viscosity, good versatility, can be cured under weak light intensity, high transparency and good flexibility.It is mainly used for fixing and arranging wires with high transparency requirements.The adhesive strength of PS and PMMA decreased at low temperature. It is suggested that the temperature of plastic substrate should be increased by pre baking, The bonding effect is better at 30-40 ℃.

Main performance index:

|

project

|

Index description

|

|

|

appearance

|

Yellowish transparent liquid

|

Visual inspection

|

|

Viscosity CPS

|

10000~15000

|

Brookfield DV - Ⅱ viscometer, 25 ℃, SC 4-15 rotor

|

|

Hardness (d)

|

55

|

GB / T 531-1999 curing test

|

|

Elongation at break%

|

-

|

GB / T 528-1998 curing test

|

|

Curing energy MJ

|

1000

|

High pressure mercury lamp

|

Typical curing properties:

K-3181 solidifies under ultraviolet light and slowly under sunlight.The light source of 220-260nm is helpful for surface curing.Curing rate, final The curing depth and surface drying effect are related to UV light source, illumination time and transmittance of material.It is suggested that the final curing process should be determined by experiments.

Dry time:

90s curing energy 400mj-125w Philips high voltage fluorescent lamp, 4.5 MW / cm 2 UVA

Full curing time:

180s - curing energy about 1000mj, 125w Philips high voltage fluorescent lamp, 4.5 MW / cm 2 UVA

Typical properties after curing:

Tensile shear strength (GB 7124-86) lap area 25 × 12.5 = 312.5mm: glass / stainless steel, ≥ 8Mpa, 30 ℃2

instructions

:

1. Clean sizing, dust, oil and dry the bonding surface before gluing, and determine the amount of dispensing as required

2. Recommended minimum light intensity 70mW / cm 2

3. Cooling devices are required for temperature sensitive materials such as thermoplastic materials

4. Check the solidification of plastic materials to prevent the liquid from causing stress cracks

5. Excess glue can be wiped off

6. The remaining glue should not be returned to the original package to avoid pollutionmatters needing attention

1. Clean sizing, dust, oil and dry the bonding surface before gluing, and determine the amount of dispensing as required

2. Recommended minimum light intensity 70mW / cm 2

3. Cooling devices are required for temperature sensitive materials such as thermoplastic materials

4. Check the solidification of plastic materials to prevent the liquid from causing stress cracks

5. Excess glue can be wiped off

6. The remaining glue should not be returned to the original package to avoid pollutionmatters needing attention

Avoid contact with eyes, skin and clothing.This product has slight irritation to eyes and skin.If it splashes into your eyes,please wash with plenty of water immediately. If you still feel unwell, please go to the hospital for examination.Wash with soapy water immediately after skin contact.Please wash the clothes after contact.Keep away from children.

keep in storage Objective:

This product is sensitive to light and heat. It needs to be stored in a cool, dry place, away from light, below 28 ℃, valid for one year.

Package specification:

50g / piece, 250G / piece or packing according to customer's requirement.

Explanation: the above data are based on our extensive experiments and the results are reliable.However, due to the diversity of practical applications, the application conditions are beyond our control, so users need to test before use to confirm whether the product is applicable.Our company does not guarantee the use of our products under specific conditions of the problem, do not bear any direct, indirect or accidental loss liability.Users in the process of using any problems, you can contact our technical service department, we will try our best to provide you with as much help as possible.

Explanation: the above data are based on our extensive experiments and the results are reliable.However, due to the diversity of practical applications, the application conditions are beyond our control, so users need to test before use to confirm whether the product is applicable.Our company does not guarantee the use of our products under specific conditions of the problem, do not bear any direct, indirect or accidental loss liability.Users in the process of using any problems, you can contact our technical service department, we will try our best to provide you with as much help as possible.

Applied Range

Hot Products

About Us

Logistic Transport

FAQ

Q: Can I buy samples placing orders?

A: Yes.Please feel free to contact us. The sample is free, you only need to pay the shipping cost.

Q: Can you provide OEM service?

A: Yes, we can produce under your own brand name. Logo and packing design need to be provided so as to make customized brand name.

Q: What is your payment term?

A: T/T, Western Union, L/C and Paypal. This is negotiable.

Q: What is the shipping method?

A: It could be shipped by sea, by air or by express(EMS, UPS, DHL, TNT, FEDEX and ect).Please confirm with us before placing orders.

Q: What other products do you have?

A: In addition to our main products are UV glue and silicone sealant, epoxy resin AB glue, we also have many other products, such as acrylic acid AB glue, anaerobic glue, instant dry glue, Ms glue, polyurethane glue and other thousands of high-performance adhesives.

|

|

Hot Searches