- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Model Number:

-

Calcium silicate board

-

High Capacity:

-

50,000m2 to 500,000m2 per year

-

Raw material:

-

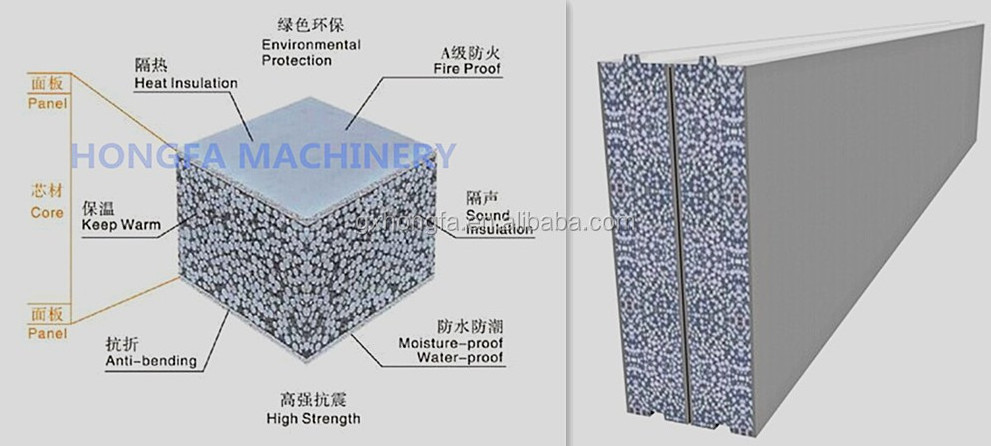

Calcium silicate board (face panel) and Cement and EPS (core)

-

Light weight:

-

60mm thickness, about 55kg/m2

-

excellent thermal conductivity:

-

≤1.45 W/m2.k

-

Standard products size:

-

1800/2440/2800mmx610mmx90/120/150/200mm

-

Advatanges:

-

Water and fire proof, lightweight

-

Insulation:

-

Reputable sound insulation

-

Easy handling:

-

Easy to cut and saw for any size and shape

-

Fast construction speed:

-

about 100m2 per day per worker

-

Certificate:

-

CE SGS ISO9001:2000

Quick Details

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Model Number:

-

Calcium silicate board

-

High Capacity:

-

50,000m2 to 500,000m2 per year

-

Raw material:

-

Calcium silicate board (face panel) and Cement and EPS (core)

-

Light weight:

-

60mm thickness, about 55kg/m2

-

excellent thermal conductivity:

-

≤1.45 W/m2.k

-

Standard products size:

-

1800/2440/2800mmx610mmx90/120/150/200mm

-

Advatanges:

-

Water and fire proof, lightweight

-

Insulation:

-

Reputable sound insulation

-

Easy handling:

-

Easy to cut and saw for any size and shape

-

Fast construction speed:

-

about 100m2 per day per worker

-

Certificate:

-

CE SGS ISO9001:2000

Calcium Silicate Faceplate Wall Panel/Polystyrene Particle Concrete Wallboard Making Machine

( 1 ) . What's the raw materials for making the Sandwich Wall Panel?

M ain raw materials of EPS wall panel are: fly ash, slag, ceramic, portland cement and EPS foam particles, the production process is simple and low cost.

( 2 ) . The light weight wall panel is suitable for modern building standard

The overall world development trend of brick from clay to non-clay, from solid to hollow, from the small to large, from heavy to light weight , from low intensity to high-strength, from high to low energy consumption. And the project is stressed to wall lightweight, high strength, thermal insulation, waste utilization, energy conservation and other functions.Therefore, the implementation of the project is imperative. The panel can meet the requirements of the modern building standard.

( 3 ) . Rich and Extensive Sources of Raw Materials.

The production of wall materials must be rich and extensive sources of raw materials. The main raw materials of wall panel are industrial residues,fly ash, slag and EPS foam particles,which not only is recycl able and reducing pollution,but also uses inexpensive ordinary chemical raw materials.The above two kinds of sources of raw materials are abundant and extensive.

( 4 ) . Obvious Advantages of Industry Competition

EPS new green wall panel has five features:

( A ) Lightweight: The raw materials used are Lightweight aggregates , fly ash ,etc , non-reinforced concrete, gravel and other heavy feedstock. So it has the characteristics of light weight , which is only 1/16 weight of the brick and concrete structure.It can significantly reduce the vertical load of the building structure and reduces building weight and project cost.

( B ) Insulation Resistance : As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products .

( C ) Permeability Resistance: The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry.

(D) F ireproof performance : this kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours.

( E ) Soundproofing : As new wall panel is using EPS as core, it has good sound insulation and air aspiration , which is more than 40 db sound insulation.

(6). With low business risk for establishing the EPS sandwich wall panel production line.

(A) long-term stability advantages: Due to the limit of functional requirements of the restrictions and sources of raw materials needed to be broad and rich , but also by limiting the requirements of the human environment, the wall construction material development developers is relatively difficult.Once this kind of wall material is successfully developed and is recognized by the government and society,its competitive advantage will be relatively stable and long-term business in the market.

(B) M echanization in production , so less workers but high output and stability.

(C) It is a comprehensive utilization of the industrial wastes project, and will get a great support from the Government .

T he three types of the machines:

1 : Horizontal type EPS wall panel making machine: high level of automatic operation,fewer workers required.

|

Horizontal Type |

|||||||

|

Overall dimensions |

Power |

Output with different thickness/pieces per mold |

|||||

|

60mm |

75mm |

90mm |

100mm |

120mm |

150mm |

||

|

2750x2504x1359 mm |

3kw |

16pcs |

14pcs |

12pcs |

12pcs |

10pcs |

8pcs |

2 : Automatic vertical type: automatic operation,high output,fewer workers required.

|

Automatic Vertical Type |

|||||||

|

Overall dimensions |

Power |

Output with different thickness/pieces per mold |

|||||

|

60mm |

75mm |

90mm |

100mm |

120mm |

150mm |

||

|

3380x3200x2680 mm |

4kw |

40pcs |

36pcs |

32pcs |

30pcs |

26pcs |

22pcs |

C: Manual vertical type partition wall board making machine: Manual operation,the highest output amount the three types, but requires more workers.

|

Manual Vertical Type |

|||||||

|

Overall dimensions |

Power |

Output with different thickness/pieces per mold |

|||||

|

60mm |

75mm |

90mm |

100mm |

120mm |

150mm |

||

|

3600x1320x2800 mm |

no |

58pcs |

50pcs |

42pcs |

40pcs |

34pcs |

28pcs |

How about your company/factory?

Hongfa company is direct factory to make the EPS wall panel machines in China since the early 1990s, is the largest and most influential manufacturer in light weight eps wall panel machines and concrete block machinery in China mainland, we have exported our machines to more than 76 countries and regions.